Question: Problem 2 ( 3 0 points ) : A two - piece pattern for the spool shown in the accompanying figure is to be sand

Problem points:

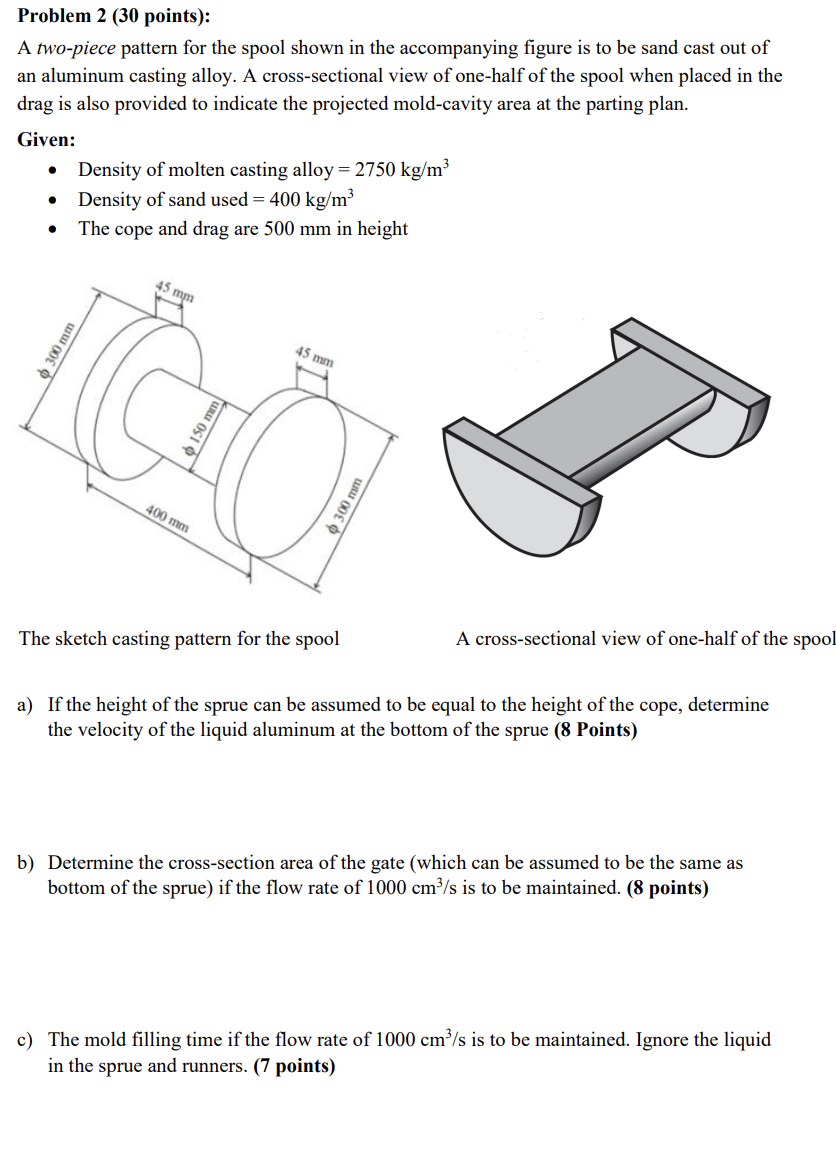

A twopiece pattern for the spool shown in the accompanying figure is to be sand cast out of

an aluminum casting alloy. A crosssectional view of onehalf of the spool when placed in the

drag is also provided to indicate the projected moldcavity area at the parting plan.

Given:

Density of molten casting alloy kgm

Density of sand used kgm

The cope and drag are mm in height

The sketch casting pattern for the spool

A crosssectional view of onehalf of the spool

a If the height of the sprue can be assumed to be equal to the height of the cope, determine

the velocity of the liquid aluminum at the bottom of the sprue Points

b Determine the crosssection area of the gate which can be assumed to be the same as

bottom of the sprue if the flow rate of cms is to be maintained. points

c The mold filling time if the flow rate of cms is to be maintained. Ignore the liquid

in the sprue and runners. points

d To save costs no clamping mechanism is allowed. If the width and length of rectangular

cope are equal, find the dimensions ie the width and length of the cope required to cast

the part without the need for clamping. Ignore the weight of the flask Points

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock