Question: Problem 2. ( 30 scores) Consider the production planning problem where an iron refinery is producing two types of steels from ore and coal. Producing

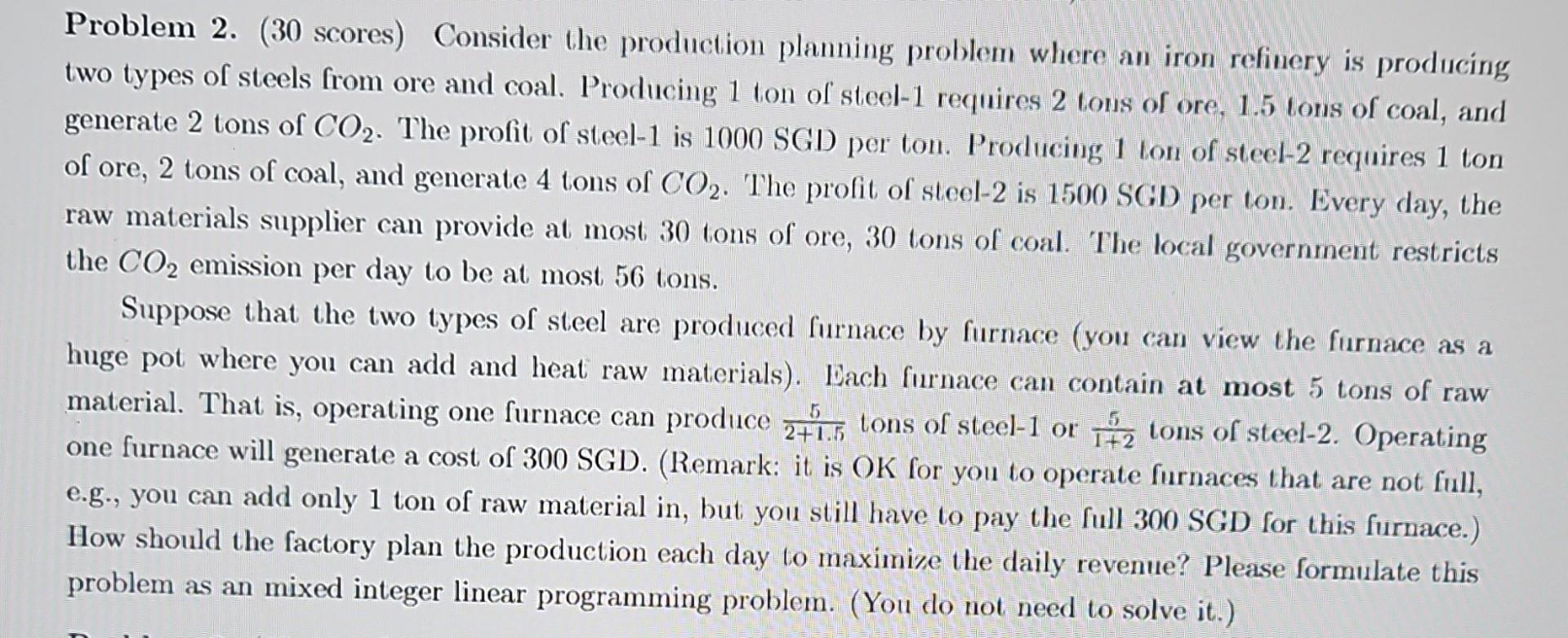

Problem 2. ( 30 scores) Consider the production planning problem where an iron refinery is producing two types of steels from ore and coal. Producing 1 ton of steel- 1 requires 2 tous of ore, 1.5 tons of coal, and generate 2 tons of CO2. The profit of steel- 1 is 1000 SGD per ton. Producing 1 ton of steel- 2 requires 1 ton of ore, 2 tons of coal, and generate 4 tons of CO2. The profit of steel- 2 is 1500SGD per ton. Every day, the raw materials supplier can provide at most 30 tons of ore, 30 tons of coal. The local government restricts the CO2 emission per day to be at most 56 tons. Suppose that the two types of steel are produced furnace by furnace (you can view the furnace as a huge pot where you can add and heat raw materials). Each furnace can contain at most 5 tons of raw material. That is, operating one furnace can produce 2+1.55 tons of steel-1 or 1+25 tons of steel-2. Operating one furnace will generate a cost of 300 SGD. (Remark: it is OK for you to operate furnaces that are not full, e.g., you can add only 1 ton of raw material in, but you still have to pay the full 300 SGD for this furnace.) How should the factory plan the production each day to maximize the daily revenue? Please formulate this problem as an mixed integer linear programming problem. (You do not need to solve it.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts