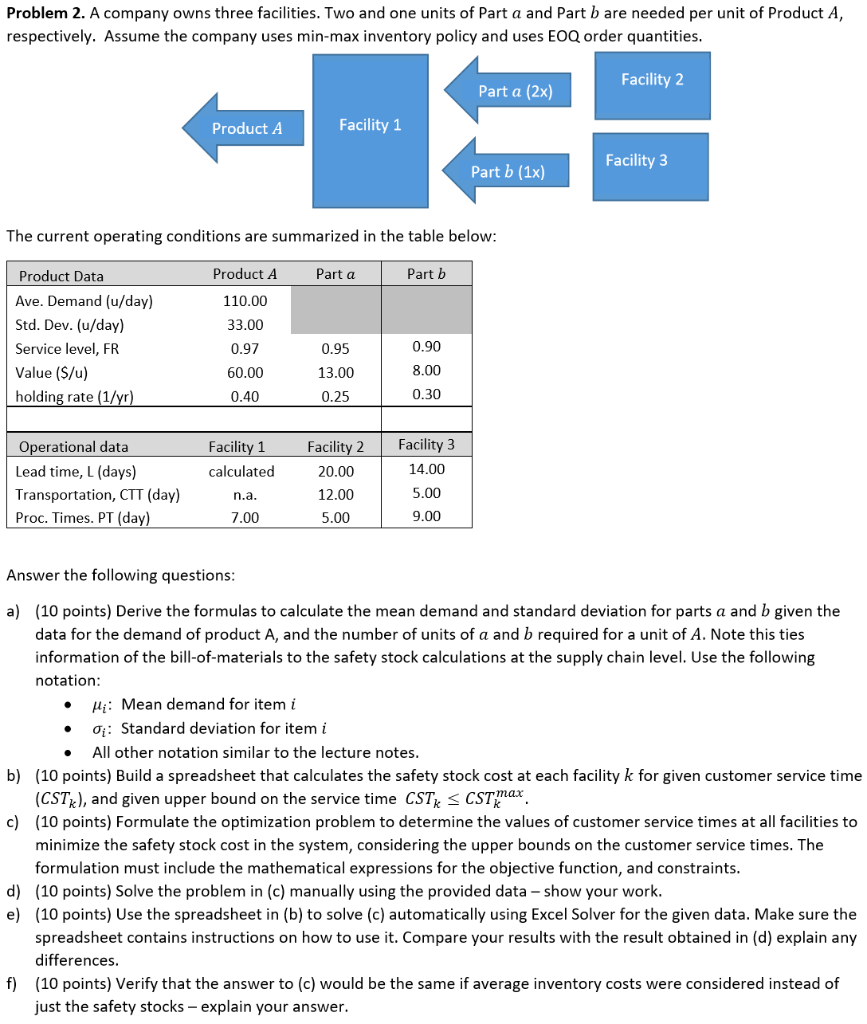

Question: Problem 2. A company owns three facilities. Two and one units of Part a and Part b are needed per unit of Product A, respectively.

Problem 2. A company owns three facilities. Two and one units of Part a and Part b are needed per unit of Product A, respectively. Assume the company uses min-max inventory policy and uses EOQ order quantities. Facility 2 Part a (2x) Product A Facility 1 Part b (1x) Facility 3 The current operating conditions are summarized in the table below: Product A Part a Part b 110.00 33.00 Product Data Ave. Demand (u/day) Std. Dev. (u/day) Service level, FR Value ($/u) holding rate (1/yr) 0.97 0.95 0.90 60.00 13.00 8.00 0.40 0.25 0.30 Facility 1 calculated Facility 3 14.00 Operational data Lead time, L (days) Transportation, CTT (day) Proc. Times. PT (day) Facility 2 20.00 12.00 5.00 n.a. 5.00 7.00 9.00 Answer the following questions: . . a) (10 points) Derive the formulas to calculate the mean demand and standard deviation for parts a and b given the data for the demand of product A, and the number of units of a and b required for a unit of A. Note this ties information of the bill-of-materials to the safety stock calculations at the supply chain level. Use the following notation: Mi: Mean demand for item i ai: Standard deviation for item i All other notation similar to the lecture notes. b) (10 points) Build a spreadsheet that calculates the safety stock cost at each facility k for given customer service time (CSTk), and given upper bound on the service time CSTK

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts