Question: Problem 2. Consider a distillation column operated at 1 atm. It separates a saturated liquid feed (flow rate: 100 kmol/hr) containing 40 mol% of hexane

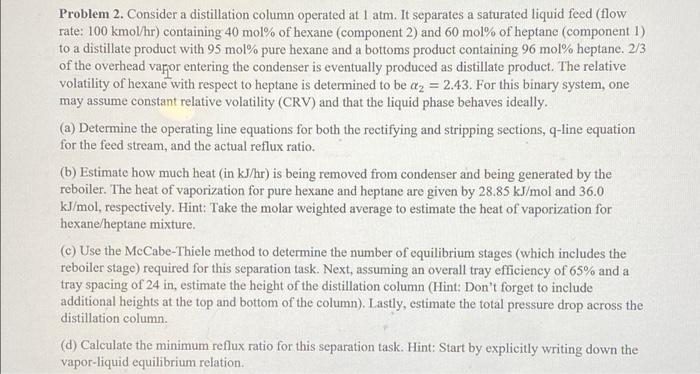

Problem 2. Consider a distillation column operated at 1 atm. It separates a saturated liquid feed (flow rate: 100 kmol/hr) containing 40 mol% of hexane (component 2) and 60 mol% of heptane (component 1) to a distillate product with 95 mol% pure hexane and a bottoms product containing 96 mol% heptane. 2/3 of the overhead vapor entering the condenser is eventually produced as distillate product. The relative volatility of hexane with respect to heptane is determined to be a 2 = 2.43. For this binary system, one may assume constant relative volatility (CRV) and that the liquid phase behaves ideally. (a) Determine the operating line equations for both the rectifying and stripping sections, q-line equation for the feed stream, and the actual reflux ratio. (b) Estimate how much heat (in kJ/hr) is being removed from condenser and being generated by the reboiler. The heat of vaporization for pure hexane and heptane are given by 28.85 kJ/mol and 36.0 kJ/mol, respectively. Hint: Take the molar weighted average to estimate the heat of vaporization for hexane/heptane mixture. (C) Use the McCabe-Thiele method to determine the number of equilibrium stages (which includes the reboiler stage) required for this separation task. Next, assuming an overall tray efficiency of 65% and a tray spacing of 24 in, estimate the height of the distillation column (Hint: Don't forget to include additional heights at the top and bottom of the column). Lastly, estimate the total pressure drop across the distillation column (d) Calculate the minimum reflux ratio for this separation task. Hint: Start by explicitly writing down the vapor-liquid equilibrium relation (e) Instead of being in saturated liquid state, suppose now the feed is in saturated vapor state. Estimate how much heat (in kJ/hr) is being generated by the reboiler to achieve the desired separation. And then, use the McCabe-Thiele method to determine the number of equilibrium stages in this case. Compare your results with what you obtain in Parts (b) and (c), and comment on how thermal quality of the feed stream affects separation performance in terms of the number of stages and reboiler heat duty requirement

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts