Question: Problem 2- Network Design problem Drylce Inc., is a manufacturer of air conditioners that has seen its demand grow significantly. The company anticipates nationwide demand

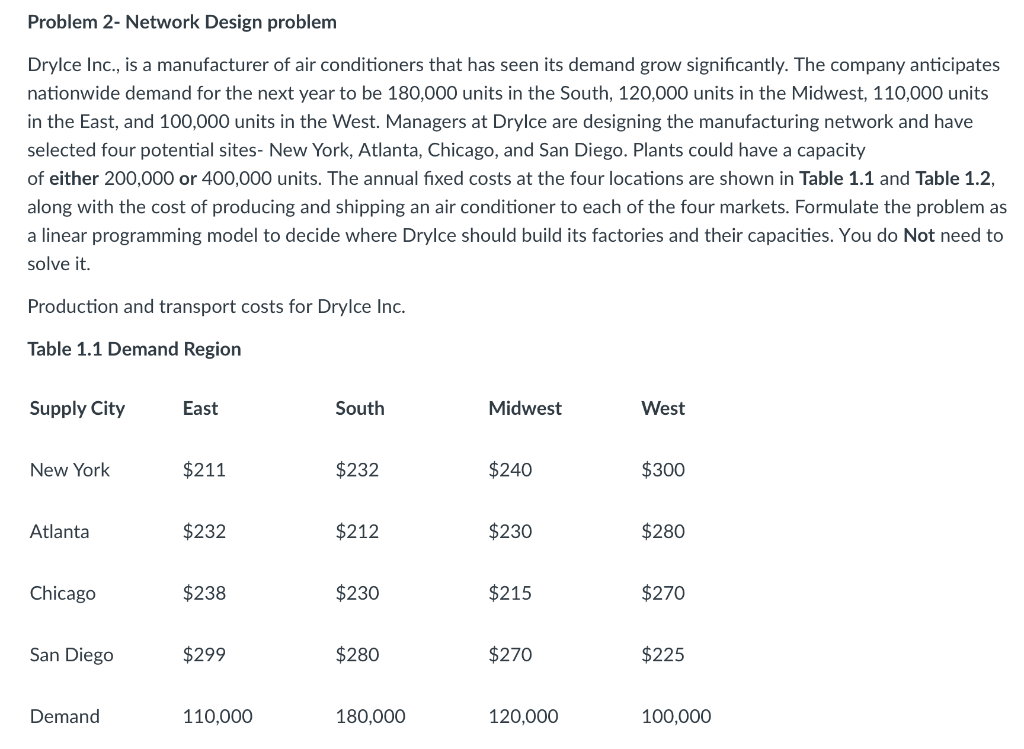

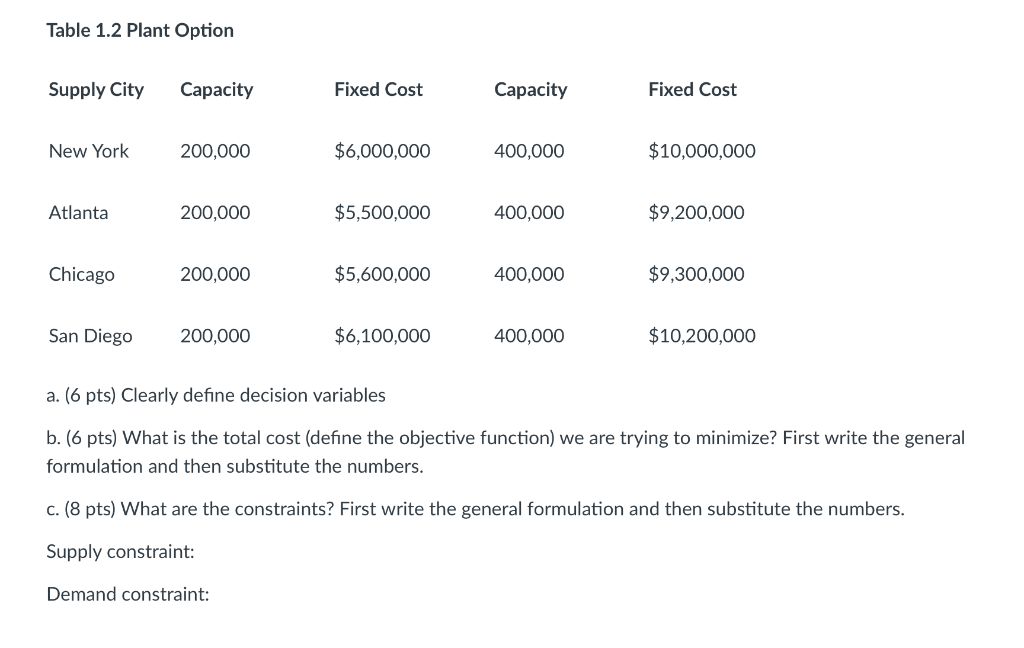

Problem 2- Network Design problem Drylce Inc., is a manufacturer of air conditioners that has seen its demand grow significantly. The company anticipates nationwide demand for the next year to be 180,000 units in the South, 120,000 units in the Midwest, 110,000 units in the East, and 100,000 units in the West. Managers at Drylce are designing the manufacturing network and have selected four potential sites- New York, Atlanta, Chicago, and San Diego. Plants could have a capacity of either 200,000 or 400,000 units. The annual fixed costs at the four locations are shown in Table 1.1 and Table 1.2, along with the cost of producing and shipping an air conditioner to each of the four markets. Formulate the problem as a linear programming model to decide where Drylce should build its factories and their capacities. You do Not need to solve it. Production and transport costs for Drylce Inc. Table 1.1 Demand Region Table 1.2 Plant Option a. (6 pts) Clearly define decision variables b. (6 pts) What is the total cost (define the objective function) we are trying to minimize? First write the general formulation and then substitute the numbers. c. (8 pts) What are the constraints? First write the general formulation and then substitute the numbers. Supply constraint: Demand constraint

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts