Question: Problem # 2 : Sizing and Rating a Shell - Tube Heat Exchanger You are asked to size a shell - and - tube heat

Problem #: Sizing and Rating a ShellTube Heat Exchanger

You are asked to size a shellandtube heat exchanger that can be used to heat up water of a flow rate from to with highpressure psi hot distilled water available at Some preliminary design considerations are given below. You are asked to size an appropriate heat exchanger by following the design method based on the economic flow velocity in tubes as introduced in this class.

Some preliminary considerations lead to the following decisions:

Fluid placement: Highpressure hot water is placed inside the tube since a highpressure of psi is involved.

Shell and head type: The Utube bundle will be used because of easy cleaning and allowing for differential thermal expansion due to the larger temperature difference between the two streams. Hence, a type of AEU exchanger is specified and there will be one shell pass but possible multiple tube passes

Tubing: Following the design guidelines for a fouling fluid service, in BWG tubes are selected to sustain highpressure.

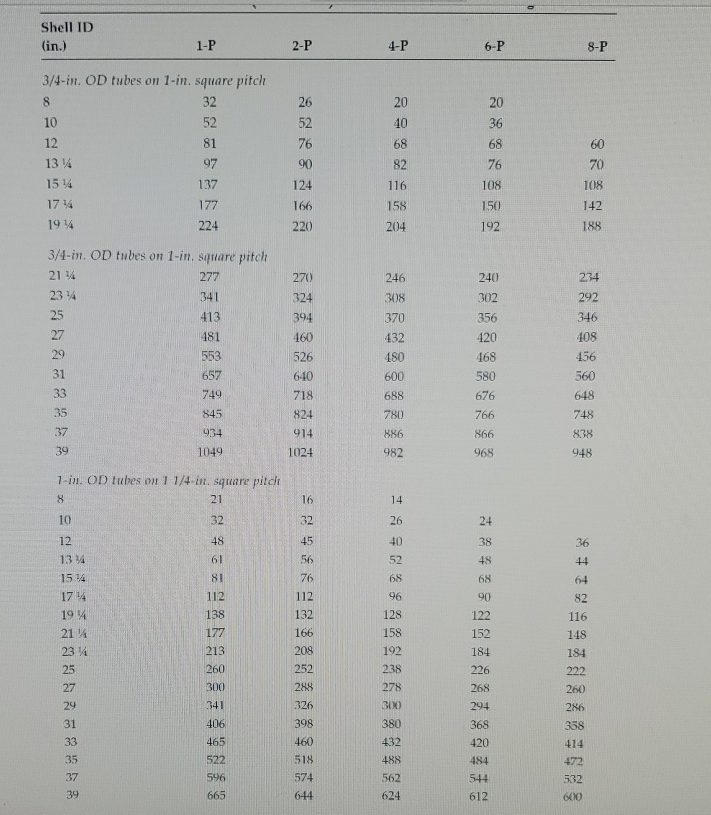

Tube layout: Since cleaning of the tube exterior surfaces is required, square pitch is specified Following the general design guidelines, for tubes a tube pitch of is specified.

You are asked to size an AEU type shell and tube heat exchanger of one shell pass by specifying the following:

tableInner diameter of shell:,

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock