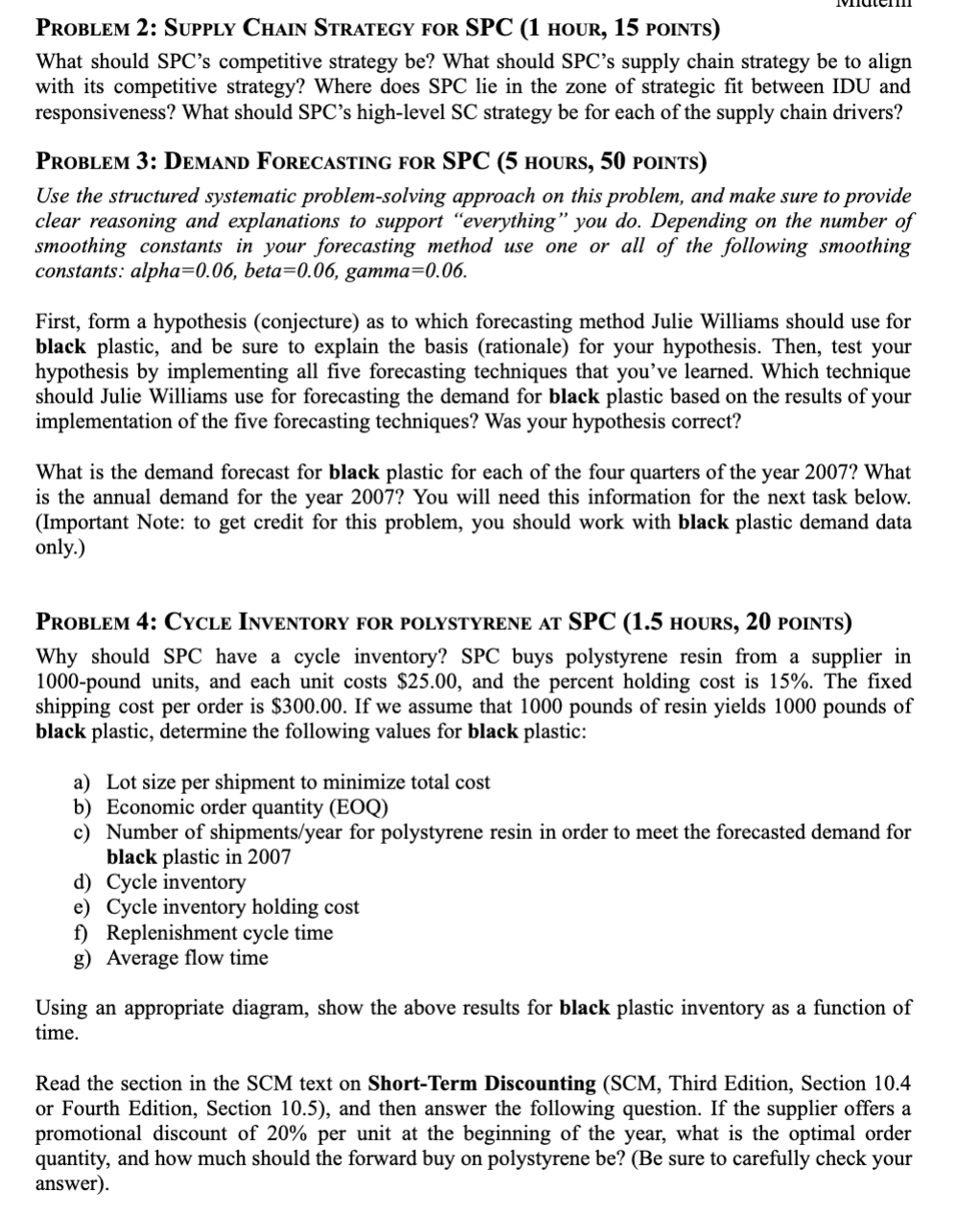

Question: Problem 2 : Supply Chain Strategy for SPC ( 1 hour, 1 5 points ) What should SPC ' s competitive strategy be ? What

Problem : Supply Chain Strategy for SPC hour, points

What should SPCs competitive strategy be What should SPCs supply chain strategy be to align

with its competitive strategy? Where does SPC lie in the zone of strategic fit between IDU and

responsiveness? What should SPCs highlevel SC strategy be for each of the supply chain drivers?

Problem : Demand Forecasting for SPC hours, points

Use the structured systematic problemsolving approach on this problem, and make sure to provide

clear reasoning and explanations to support "everything" you do Depending on the number of

smoothing constants in your forecasting method use one or all of the following smoothing

constants: alpha beta gamma

First, form a hypothesis conjecture as to which forecasting method Julie Williams should use for

black plastic, and be sure to explain the basis rationale for your hypothesis. Then, test your

hypothesis by implementing all five forecasting techniques that you've learned. Which technique

should Julie Williams use for forecasting the demand for black plastic based on the results of your

implementation of the five forecasting techniques? Was your hypothesis correct?

What is the demand forecast for black plastic for each of the four quarters of the year What

is the annual demand for the year You will need this information for the next task below.

Important Note: to get credit for this problem, you should work with black plastic demand data

only.

Problem : Cycle Inventory for polystyrene at SPC hours, points

Why should SPC have a cycle inventory? SPC buys polystyrene resin from a supplier in

pound units, and each unit costs $ and the percent holding cost is The fixed

shipping cost per order is $ If we assume that pounds of resin yields pounds of

black plastic, determine the following values for black plastic:

a Lot size per shipment to minimize total cost

b Economic order quantity EOQ

c Number of shipmentsyear for polystyrene resin in order to meet the forecasted demand for

black plastic in

d Cycle inventory

e Cycle inventory holding cost

f Replenishment cycle time

g Average flow time

Using an appropriate diagram, show the above results for black plastic inventory as a function of

time.

Read the section in the SCM text on ShortTerm Discounting SCM Third Edition, Section

or Fourth Edition, Section and then answer the following question. If the supplier offers a

promotional discount of per unit at the beginning of the year, what is the optimal order

quantity, and how much should the forward buy on polystyrene beBe sure to carefully check your

answer

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock