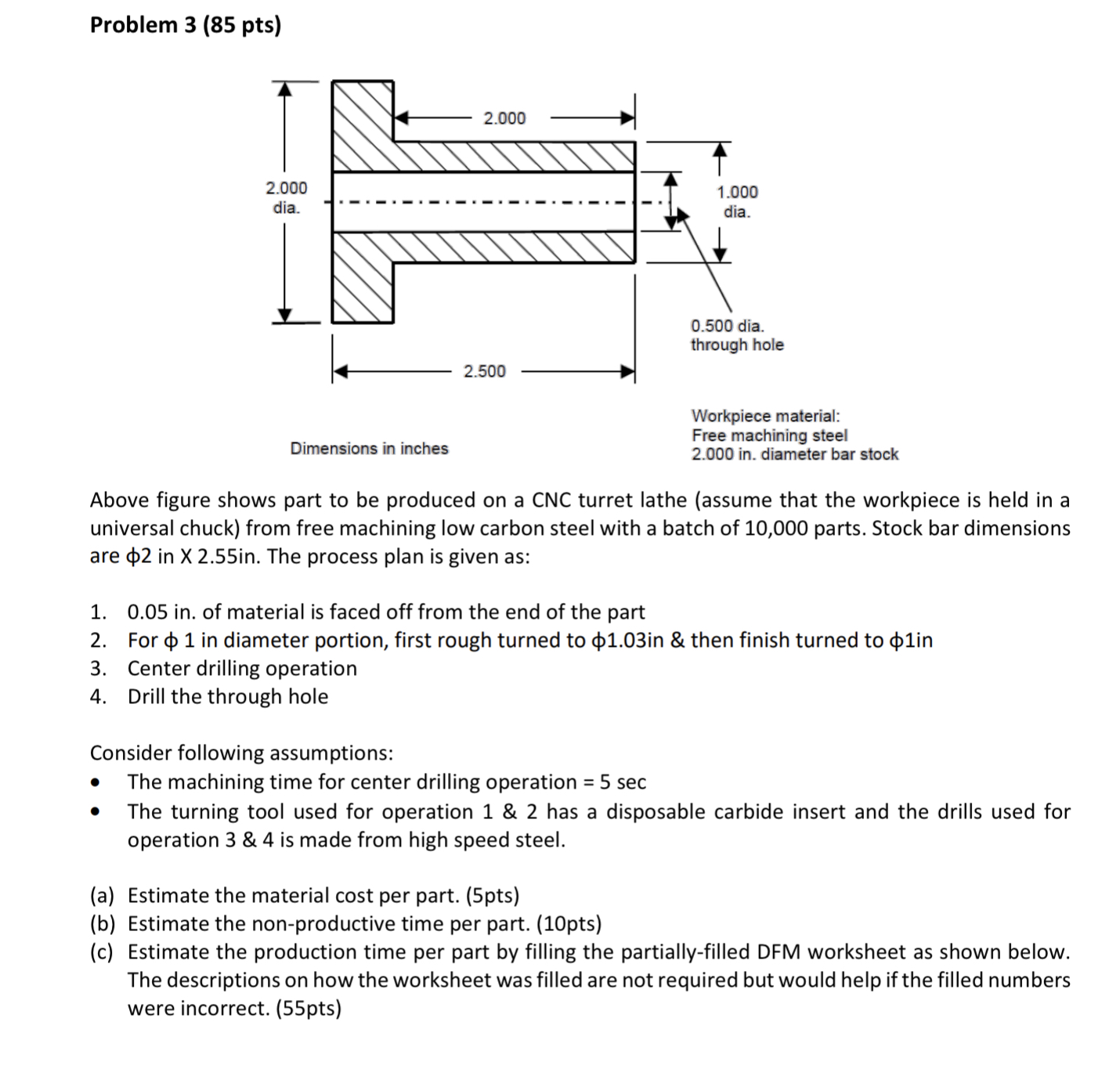

Question: Problem 3 (85 pts) 2.000 dia. 2.000 2.500 1.000 dia. 0.500 dia. through hole Dimensions in inches Workpiece material: Free machining steel 2.000 in.

Problem 3 (85 pts) 2.000 dia. 2.000 2.500 1.000 dia. 0.500 dia. through hole Dimensions in inches Workpiece material: Free machining steel 2.000 in. diameter bar stock Above figure shows part to be produced on a CNC turret lathe (assume that the workpiece is held in a universal chuck) from free machining low carbon steel with a batch of 10,000 parts. Stock bar dimensions are $2 in X 2.55in. The process plan is given as: 1. 0.05 in. of material is faced off from the end of the part 2. For 1 in diameter portion, first rough turned to 1.03in & then finish turned to 1in 3. Center drilling operation 4. Drill the through hole Consider following assumptions: The machining time for center drilling operation = 5 sec The turning tool used for operation 1 & 2 has a disposable carbide insert and the drills used for operation 3 & 4 is made from high speed steel. (a) Estimate the material cost per part. (5pts) (b) Estimate the non-productive time per part. (10pts) (c) Estimate the production time per part by filling the partially-filled DFM worksheet as shown below. The descriptions on how the worksheet was filled are not required but would help if the filled numbers were incorrect. (55pts)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts