Question: Problem 3: A machining shop has a single CNC milling machine for producing various mold inserts for injection molding, including oval, beveled, chamfered, and rounded

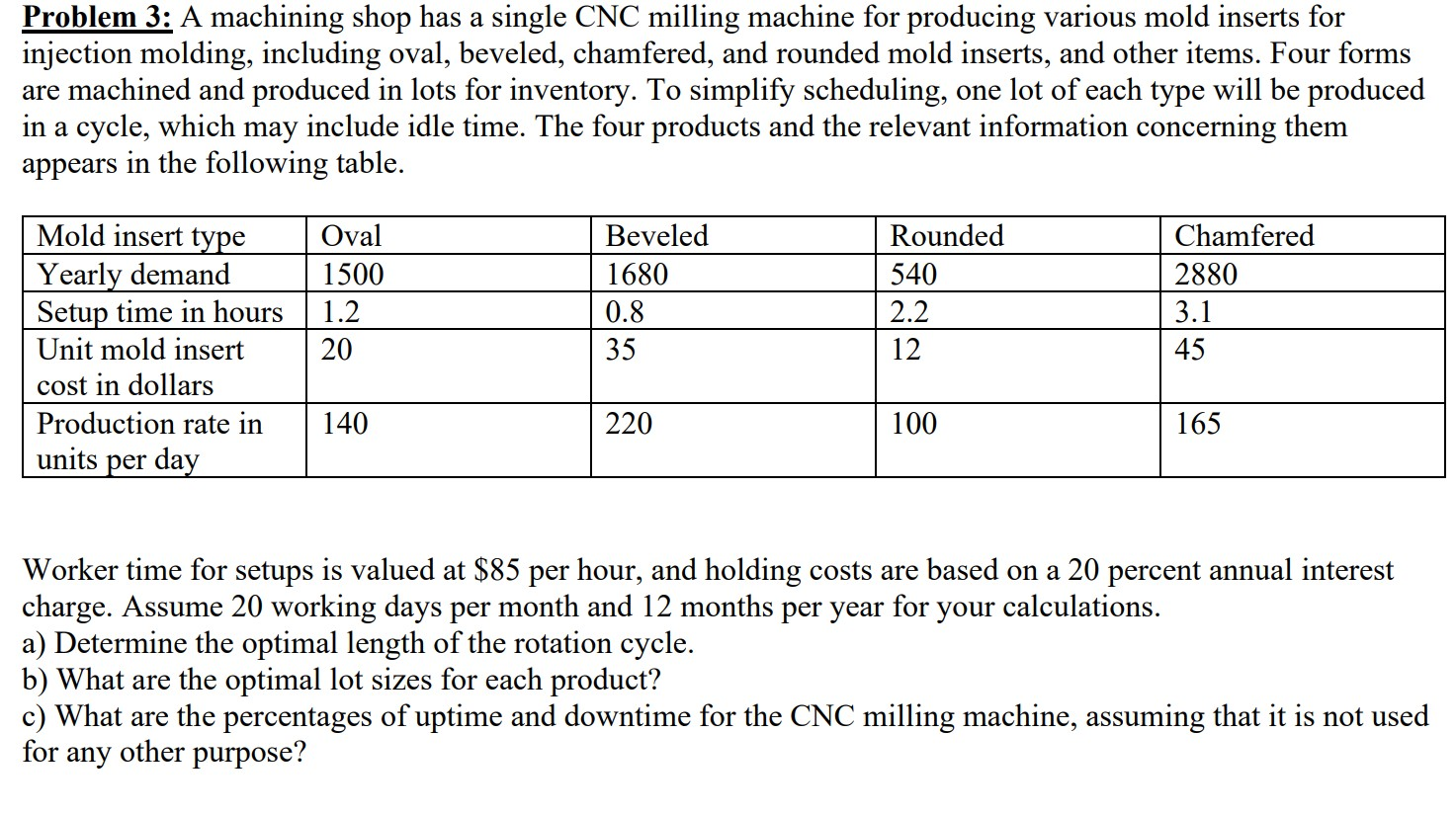

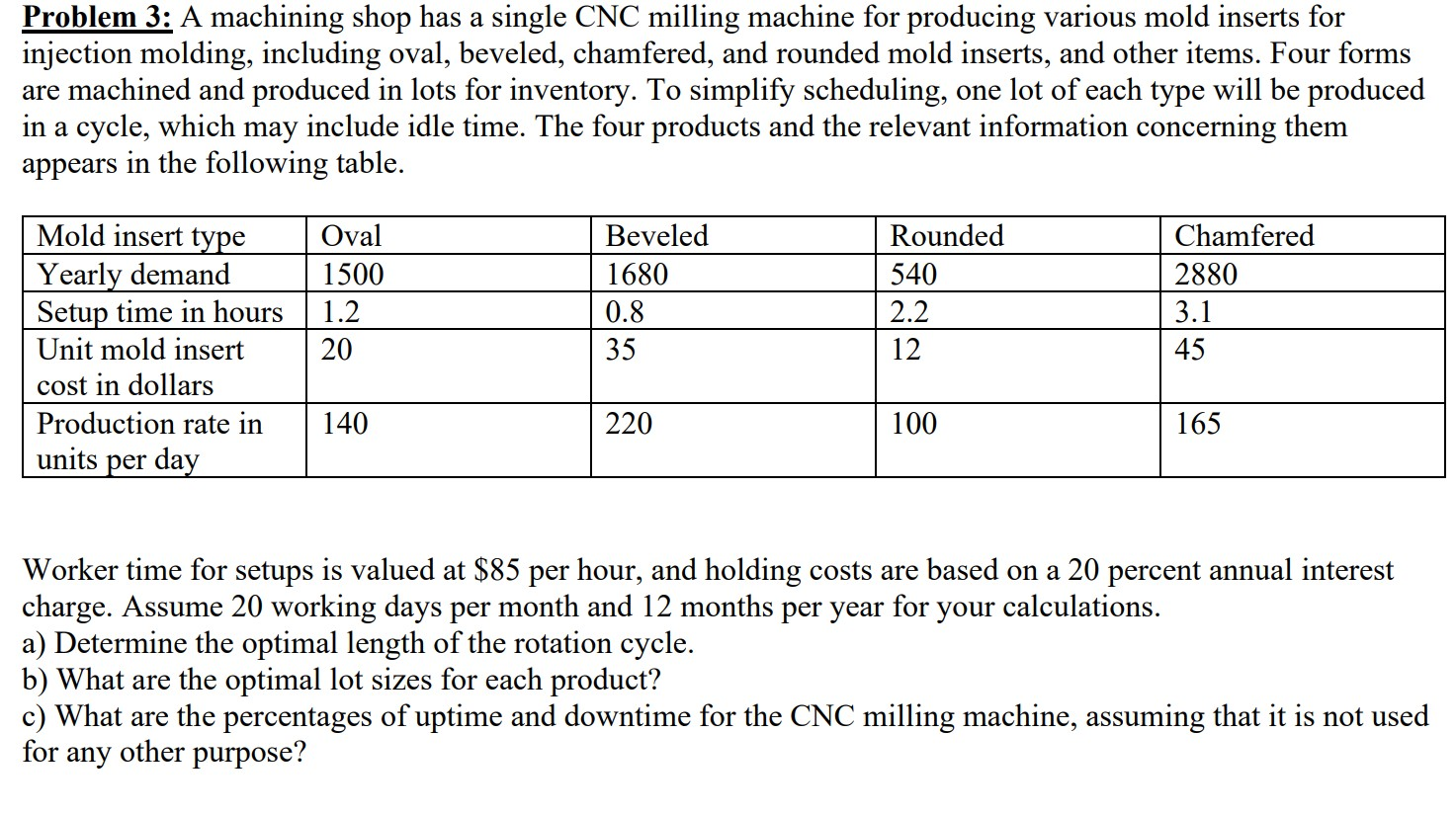

Problem 3: A machining shop has a single CNC milling machine for producing various mold inserts for injection molding, including oval, beveled, chamfered, and rounded mold inserts, and other items. Four forms are machined and produced in lots for inventory. To simplify scheduling, one lot of each type will be produced in a cycle, which may include idle time. The four products and the relevant information concerning them appears in the following table. Mold insert type Yearly demand Setup time in hours Unit mold insert cost in dollars Production rate in units per day Oval 1500 1.2 20 Beveled 1680 0.8 35 Rounded 540 2.2 12 Chamfered 2880 3.1 45 140 220 100 165 Worker time for setups is valued at $85 per hour, and holding costs are based on a 20 percent annual interest charge. Assume 20 working days per month and 12 months per year for your calculations. a) Determine the optimal length of the rotation cycle. b) What are the optimal lot sizes for each product? c) What are the percentages of uptime and downtime for the CNC milling machine, assuming that it is not used for any other purpose? Problem 3: A machining shop has a single CNC milling machine for producing various mold inserts for injection molding, including oval, beveled, chamfered, and rounded mold inserts, and other items. Four forms are machined and produced in lots for inventory. To simplify scheduling, one lot of each type will be produced in a cycle, which may include idle time. The four products and the relevant information concerning them appears in the following table. Mold insert type Yearly demand Setup time in hours Unit mold insert cost in dollars Production rate in units per day Oval 1500 1.2 20 Beveled 1680 0.8 35 Rounded 540 2.2 12 Chamfered 2880 3.1 45 140 220 100 165 Worker time for setups is valued at $85 per hour, and holding costs are based on a 20 percent annual interest charge. Assume 20 working days per month and 12 months per year for your calculations. a) Determine the optimal length of the rotation cycle. b) What are the optimal lot sizes for each product? c) What are the percentages of uptime and downtime for the CNC milling machine, assuming that it is not used for any other purpose