Question: (Problem 4) John Doe, operations manager at ABC electronics, has the following demand forecasting for one year in his factory: Quarter Q 1 Q2 Q3

(Problem 4) John Doe, operations manager at ABC electronics, has the following demand forecasting for one year in his factory:

| Quarter | Q 1 | Q2 | Q3 | Q4 |

| Demand | 10,000 | 20,000 | 16,000 | 4,000 |

At the beginning of quarter 1, there are 2,000 units in inventory. The firm has prepared the following data:

Hiring cost = $200/person

Firing cost = $400/person

Beginning workforce = 60 employees

Inventory carrying cost = $2/unit/quarter

Stock out cost = $5/unit/quarter (Max. Stock-out is 1,000 units/quarter)

Regular payroll = $1,200/employee/quarter

Overtime cost = $7/unit

Subcontract cost = $8/unit (lower and upper limits for the subcontracts are 1,000 units and 3,000 units per quarter)

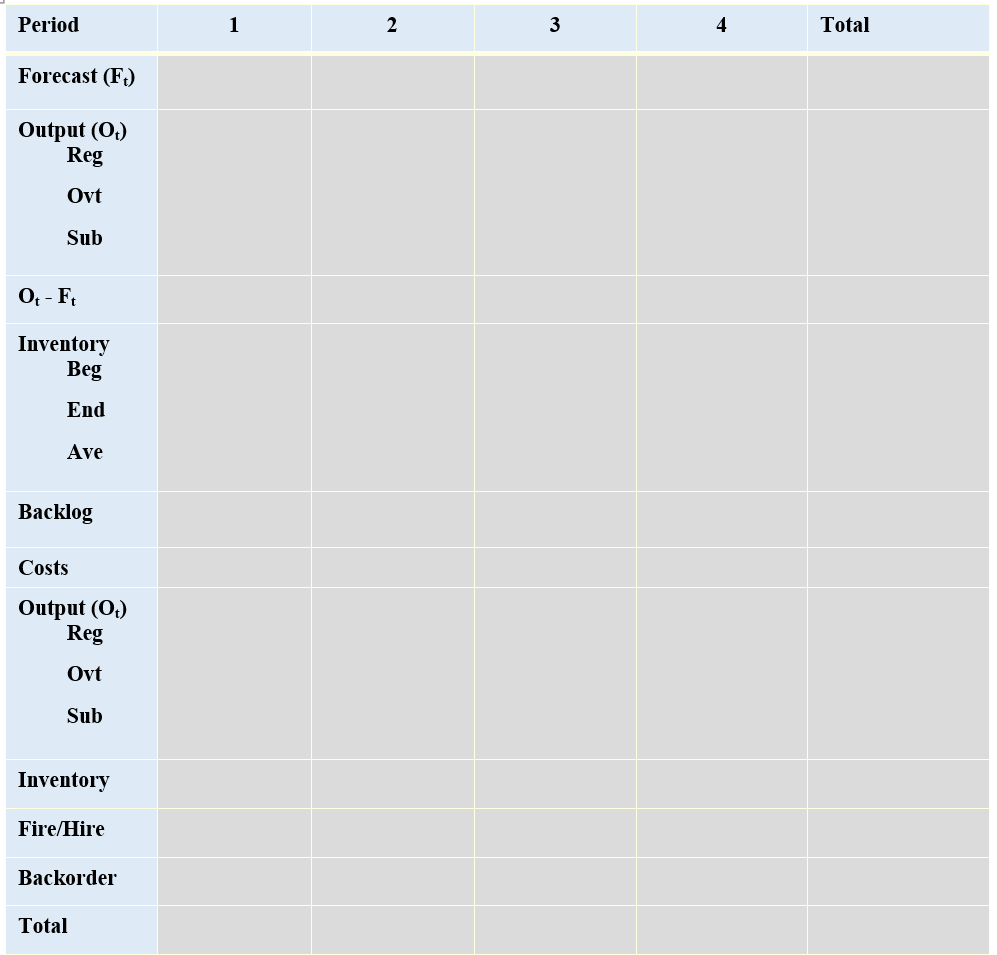

Each employee can produce 200 units per quarter. Demand not satisfied in any quarter is lost and incurs a stock-out penalty. Overtime capacity is 50 units per employee per quarter. When you hire workers, you cannot fire them within a year. Develop a feasible plan (level, chase, or mixed) that provides for an inventory of at least 1,000 units but no more than 3,000 units at the end of the year. Use the aggregate planning form attached next page.

Please complete this ONLY using chase, level or mix strategy. Don't use solver in excel.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts