Question: Problem 4(a) A working part costing $80 is processed through the factory. The manufacturing lead time for the part is 12 weeks, and the total

Problem 4(a)

A working part costing $80 is processed through the factory. The manufacturing lead time for the part is 12 weeks, and the total time spent in processing during the lead time is 30h for all operations at a rate of $35/h. Non-operation costs total $70 during the lead time. The holding cost rate used by the company for work-in-process is 26%. The plant operates 40h/week, 52 weeks per year. If this part is typical of the 200 parts per week processed through the factory:

a) Determine the holding cost per part during the manufacturing lead time.

b) Determine the total annual holding costs to the factory.

c) If the manufacturing lead time were to be reduced from 12 weeks to 8 weeks, how much would the total holding costs be reduced on an annual basis?

Problem 4(b)

COURSE: Intelligent Production Systems

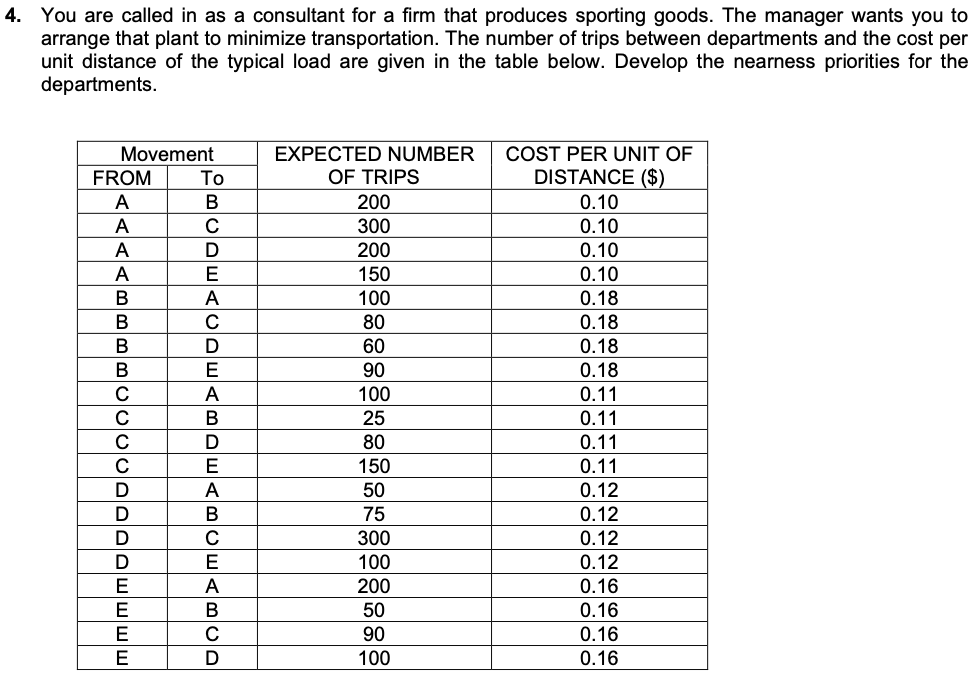

4. You are called in as a consultant for a firm that produces sporting goods. The manager wants you to arrange that plant to minimize transportation. The number of trips between departments and the cost per unit distance of the typical load are given in the table below. Develop the nearness priorities for the departments. Movement FROM To A B A C A D E B A B B D B E A B D E A D B D C D E E A E B E C E D EXPECTED NUMBER OF TRIPS 200 300 200 150 100 80 60 90 100 25 80 150 50 75 300 100 200 50 90 100 COST PER UNIT OF DISTANCE ($) 0.10 0.10 0.10 0.10 0.18 0.18 0.18 0.18 0.11 0.11 0.11 0.11 0.12 0.12 0.12 0.12 0.16 0.16 0.16 0.16Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts