Question: Problem 5 In a soap manufacturing process, a cold die initially at - 2 0 C compresses soap material initially at + 2 0 C

Problem

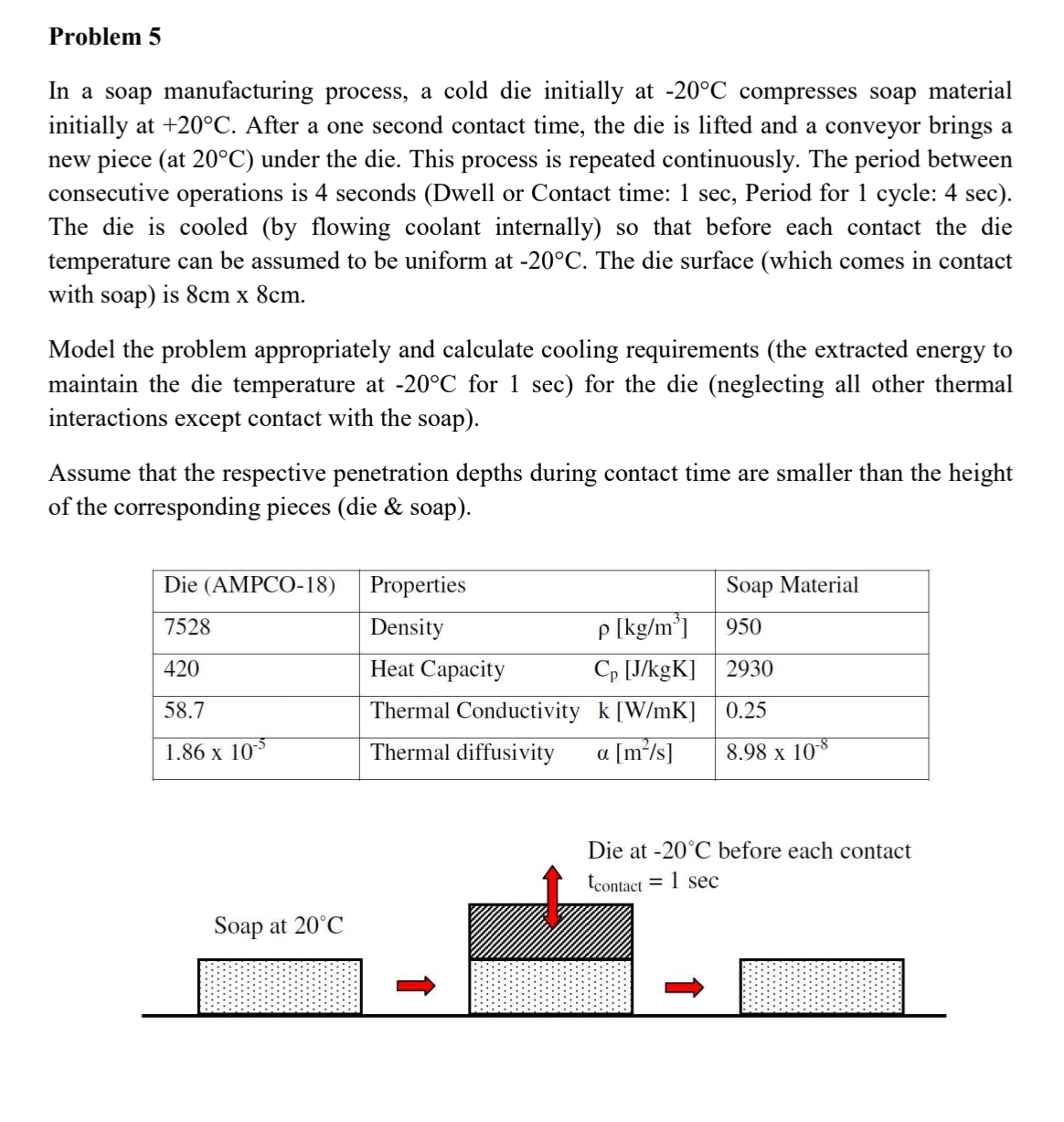

In a soap manufacturing process, a cold die initially at compresses soap material

initially at After a one second contact time, the die is lifted and a conveyor brings a

new piece at under the die. This process is repeated continuously. The period between

consecutive operations is seconds Dwell or Contact time: sec Period for cycle:

The die is cooled by flowing coolant internally so that before each contact the die

temperature can be assumed to be uniform at The die surface which comes in contact

with soap is

Model the problem appropriately and calculate cooling requirements the extracted energy to

maintain the die temperature at for sec for the die neglecting all other thermal

interactions except contact with the soap

Assume that the respective penetration depths during contact time are smaller than the height

of the corresponding pieces die & soap

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock