Question: Problem 6. (10 marks) a. Lear Corporation in Ajax assembles car seats for Fiat Chrysler in Brampton, Ontario. Assume that the company makes the seats

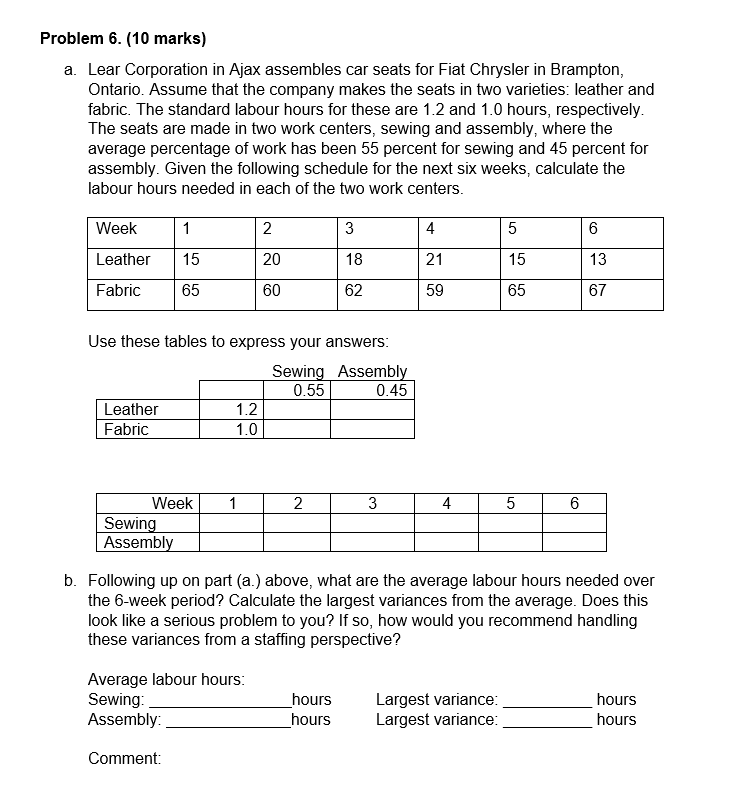

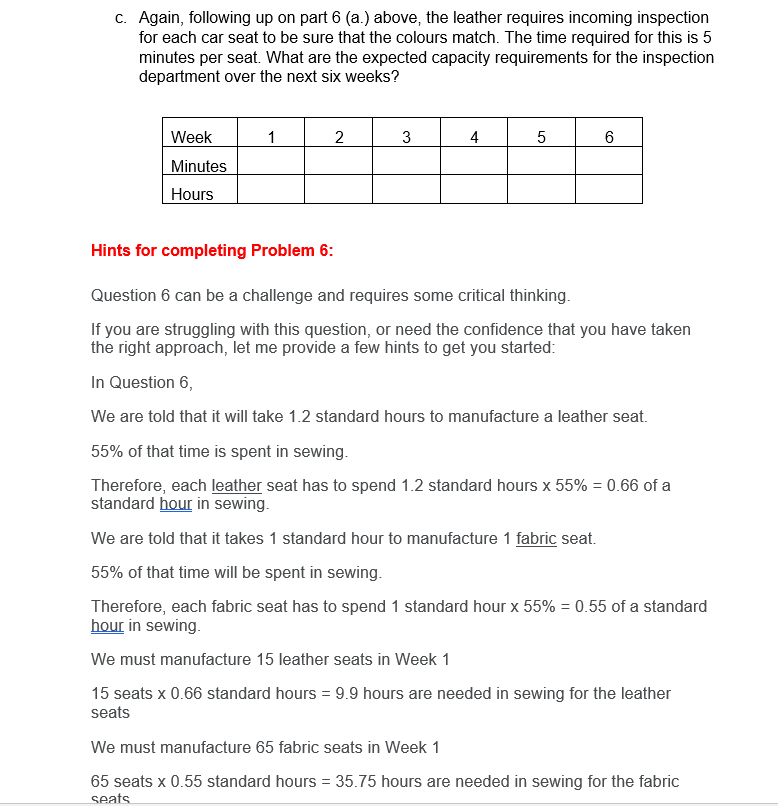

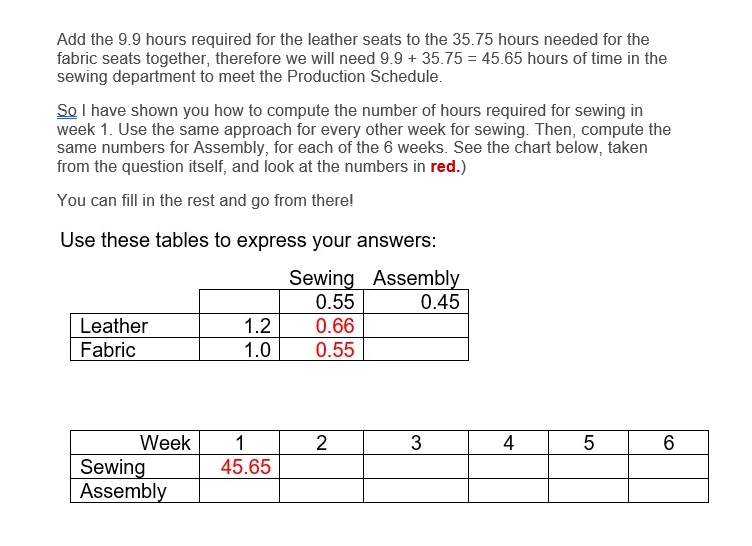

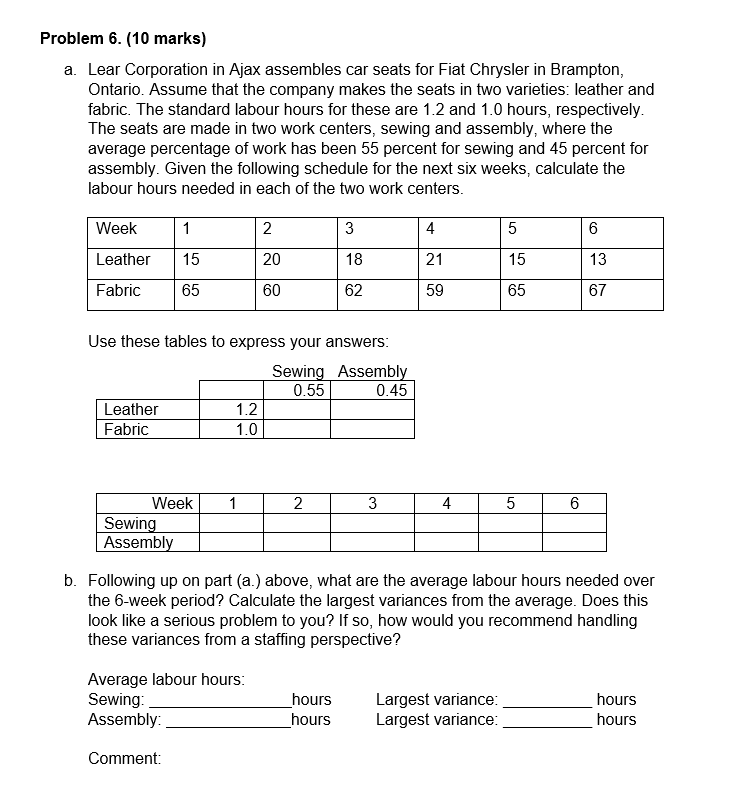

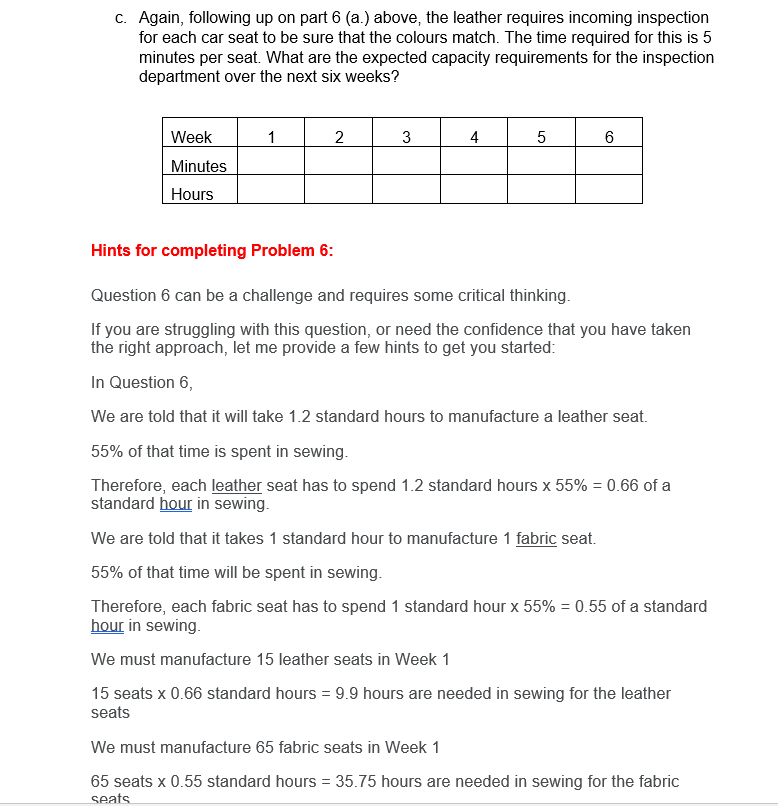

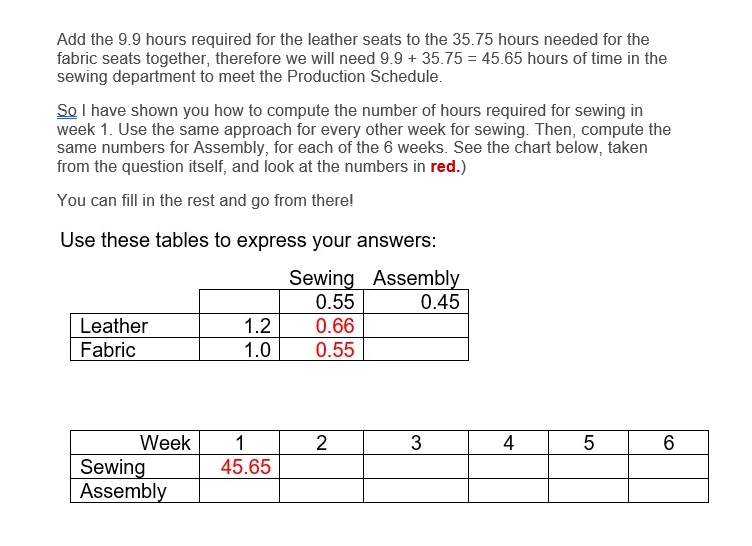

Problem 6. (10 marks) a. Lear Corporation in Ajax assembles car seats for Fiat Chrysler in Brampton, Ontario. Assume that the company makes the seats in two varieties: leather and fabric. The standard labour hours for these are 1.2 and 1.0 hours, respectively. The seats are made in two work centers, sewing and assembly, where the average percentage of work has been 55 percent for sewing and 45 percent for assembly. Given the following schedule for the next six weeks, calculate the labour hours needed in each of the two work centers. Week 1 2 3 4 5 6 Leather 15 20 18 21 15 13 Fabric 65 60 62 59 65 67 Use these tables to express your answers: Sewing Assembly 0.55 0.45 Leather 1.2 Fabric 1.0 1 2 3 4 5 6 Week Sewing Assembly b. Following up on part (a.) above, what are the average labour hours needed over the 6-week period? Calculate the largest variances from the average. Does this look like a serious problem to you? If so, how would you recommend handling these variances from a staffing perspective? Average labour hours: Sewing: Assembly: hours hours Largest variance: Largest variance: hours hours Comment: C. Again, following up on part 6 (a.) above, the leather requires incoming inspection for each car seat to be sure that the colours match. The time required for this is 5 minutes per seat. What are the expected capacity requirements for the inspection department over the next six weeks? 1 2 3 4 5 6 Week Minutes Hours Hints for completing Problem 6: Question 6 can be a challenge and requires some critical thinking. If you are struggling with this question, or need the confidence that you have taken the right approach, let me provide a few hints to get you started: In Question 6, We are told that it will take 1.2 standard hours to manufacture a leather seat. 55% of that time is spent in sewing. Therefore, each leather seat has to spend 1.2 standard hours x 55% = 0.66 of a standard hour in sewing. We are told that it takes 1 standard hour to manufacture 1 fabric seat. 55% of that time will be spent in sewing. Therefore, each fabric seat has to spend 1 standard hour x 55% = 0.55 of a standard hour in sewing. We must manufacture 15 leather seats in Week 1 15 seats x 0.66 standard hours = 9.9 hours are needed in sewing for the leather seats We must manufacture 65 fabric seats in Week 1 65 seats x 0.55 standard hours = 35.75 hours are needed in sewing for the fabric seats Add the 9.9 hours required for the leather seats to the 35.75 hours needed for the fabric seats together, therefore we will need 9.9 + 35.75 = 45.65 hours of time in the sewing department to meet the Production Schedule. So I have shown you how to compute the number of hours required for sewing in week 1. Use the same approach for every other week for sewing. Then, compute the same numbers for Assembly, for each of the 6 weeks. See the chart below, taken from the question itself, and look at the numbers in red.) You can fill in the rest and go from there! Use these tables to express your answers: Sewing Assembly 0.55 0.45 Leather 1.2 0.66 Fabric 1.0 0.55 2 3 4 5 6 Week Sewing Assembly 1 45.65