Question: Problem 8 (5 marks) Mitchell's Makeshift Manufacturing facility has three departments: shaping, pickling, and packaging. Mitchell's orders averaged 100 pieces each. Each of the three

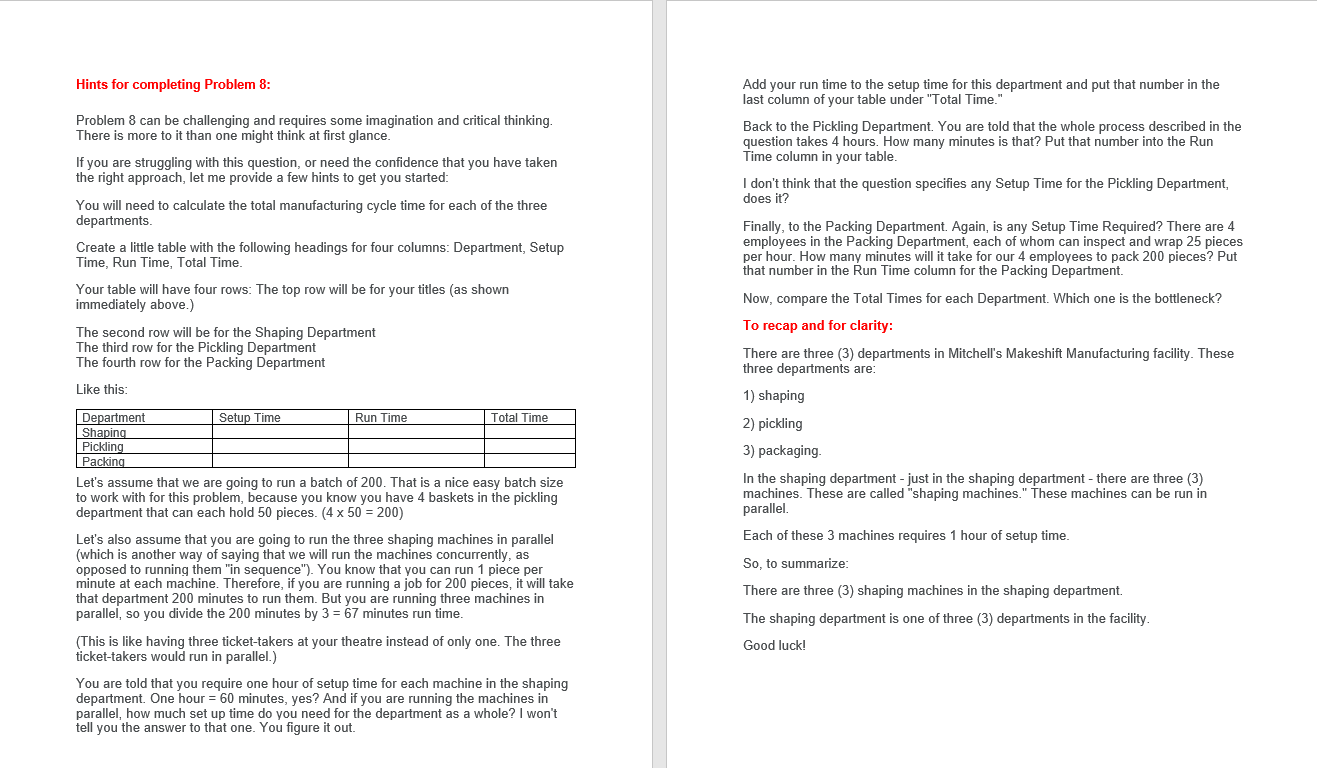

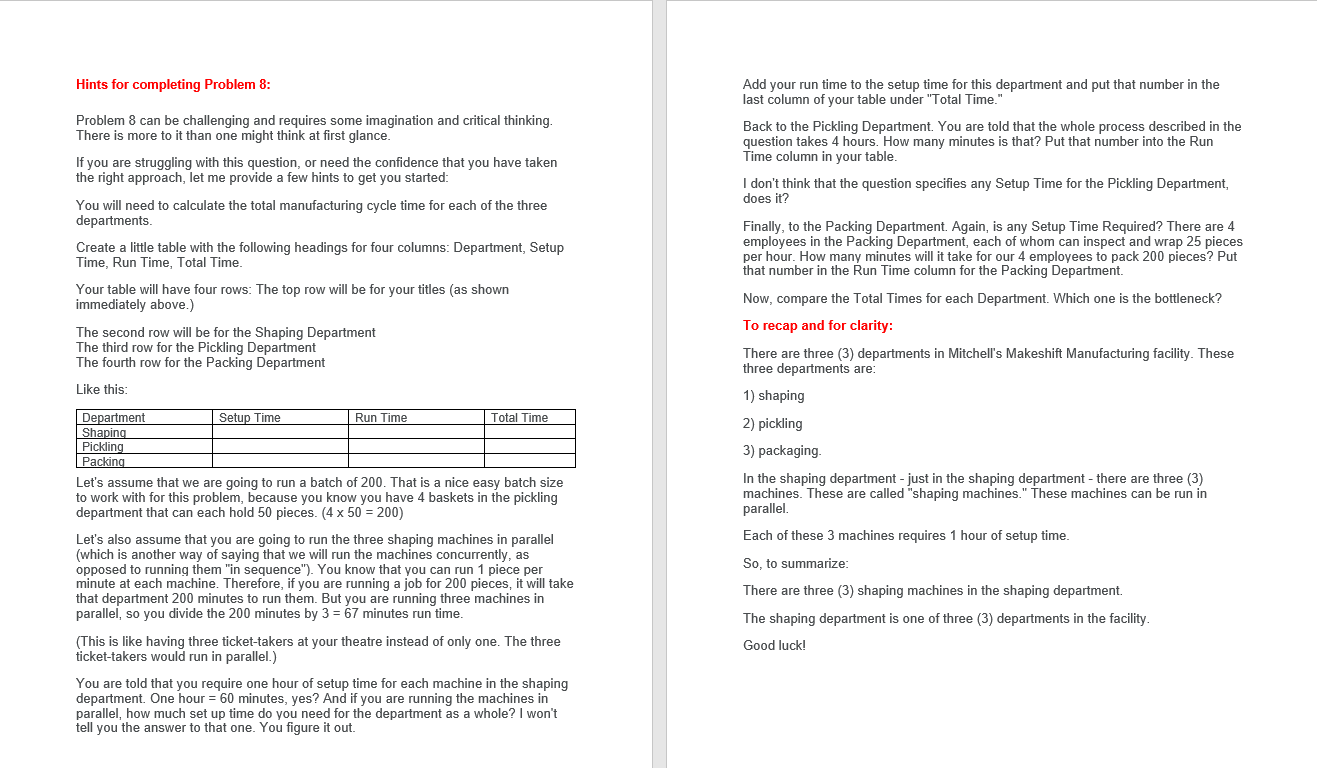

Problem 8 (5 marks) Mitchell's Makeshift Manufacturing facility has three departments: shaping, pickling, and packaging. Mitchell's orders averaged 100 pieces each. Each of the three shaping machines require one hour of setup but could run a piece in one minute. The shaping machines can run in parallel. The pickling department lowered baskets of pieces into brine tanks and subjected them to a low-voltage current, a heating and cooling, and a rinse. The whole process took 4 hours for any number of baskets or pieces. The only brine tank at the facility could hold four baskets, each of which could contain 50 pieces. (Baskets were loaded while another load was in the tank.) Each piece was inspected and wrapped in the packing department. Each of the four people in the packing department could do this at the rate of 25 pieces per hour. Mitchell had heard of the Theory of Constraints (TOC) and wanted to identify the bottleneck department. Which is it? (Show your calculations and / or reasoning for your answer). Here is the space to show your answer: Hints for completing Problem 8: Add your run time to the setup time for this department and put that number in the last column of your table under "Total Time. Back to the Pickling Department. You are told that the whole process described in the question takes 4 hours. How many minutes is that? Put that number into the Run Time column in your table. I don't think that the question specifies any Setup Time for the Pickling Department, does it? Problem 8 can be challenging and requires some imagination and critical thinking. There is more to it than one might think at first glance. If you are struggling with this question, or need the confidence that you have taken the right approach, let me provide a few hints to get you started: You will need to calculate the total manufacturing cycle time for each of the three departments Create a little table with the following headings for four columns: Department, Setup Time, Run Time, Total Time. Your table will have four rows: The top row will be for your titles (as shown immediately above.) Finally, to the Packing Department. Again, is any Setup Time Required? There are 4 employees in the Packing Department, each of whom can inspect and wrap 25 pieces per hour. How many minutes will it take for our 4 employees to pack 200 pieces? Put that number in the Run Time column for the Packing Department. Now, compare the Total Times for each Department. Which one is the bottleneck? To recap and for clarity: There are three (3) departments in Mitchell's Makeshift Manufacturing facility. These three departments are: 1) shaping The second row will be for the Shaping Department The third row for the Pickling Department The fourth row for the Packing Department Like this: : Department Setup Time Run Time Total Time Shaping Pickling | Packing Let's assume that we are going to run a batch of 200. That is a nice easy batch size to work with for this problem, because you know you have 4 baskets in the pickling department that can each hold 50 pieces. (4 x 50 = 200) Let's also assume that you are going to run the three shaping machines in parallel (which is another way of saying that we will run the machines concurrently, as opposed to running them "in sequence"). You know that you can run 1 piece per minute at each machine. Therefore, if you are running a job for 200 pieces, it will take that department 200 minutes to run them. But you are running three machines in parallel, so you divide the 200 minutes by 3 = 67 minutes run time. (This is like having three ticket-takers at your theatre instead of only one. The three ticket-takers would run in parallel.) You are told that you require one hour of setup time for each machine in the shaping department. One hour = 60 minutes, yes? And if you are running the machines in parallel, how much set up time do you need for the department as a whole? I won't tell you the answer to that one. You figure it out. 2) pickling 3) packaging In the shaping department - just in the shaping department - there are three (3) machines. These are called "shaping machines." These machines can be run in parallel. Each of these 3 machines requires 1 hour of setup time. So, to summarize: There are three (3) shaping machines in the shaping department. The shaping department is one of three (3) departments in the facility Good luck