Question: Problem 9 . Cold and Hot Working Processes and Mechanical Properties We wish to produce a 0 . 3 - in . thick plate of

Problem Cold and Hot Working Processes and Mechanical Properties

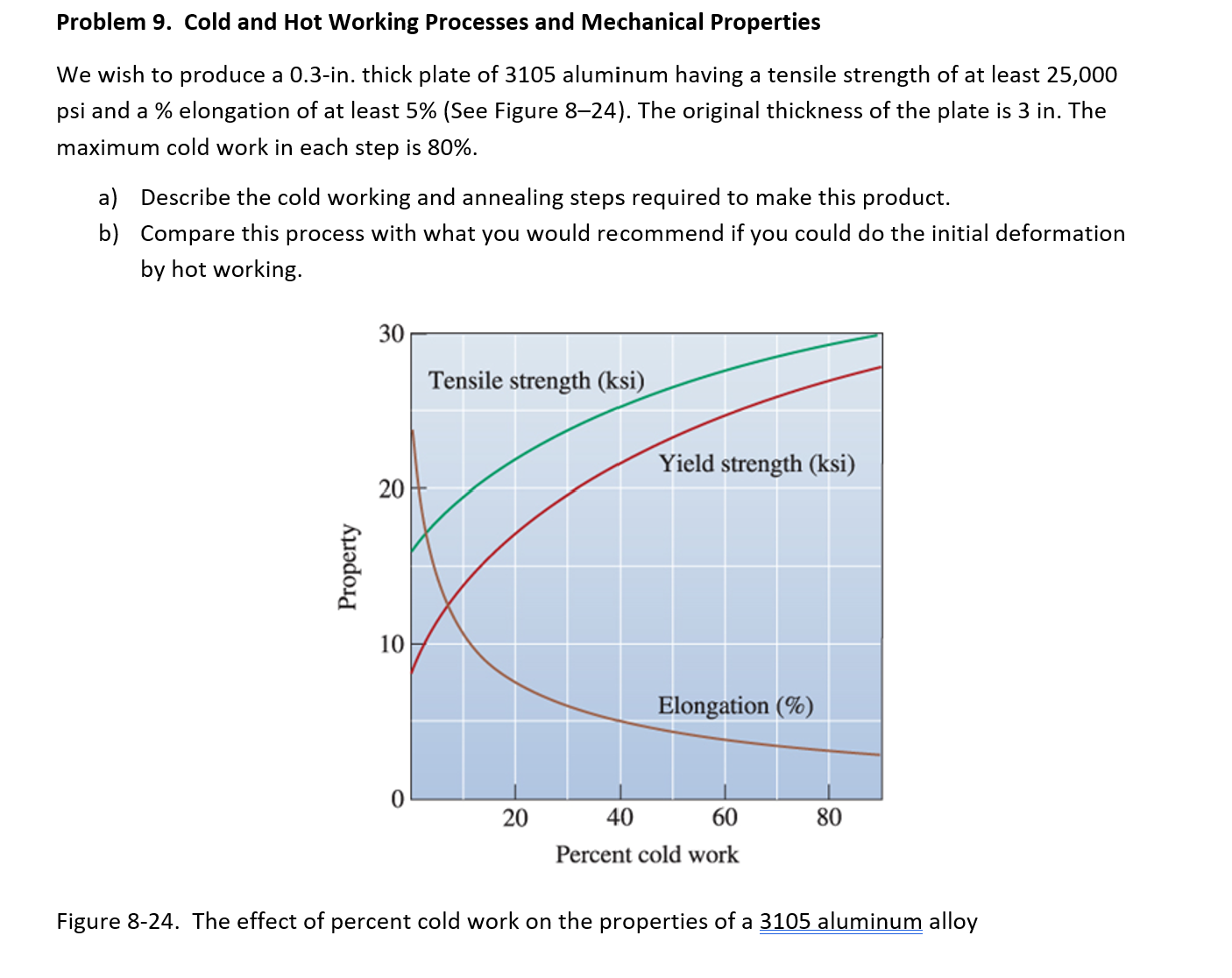

We wish to produce a in thick plate of aluminum having a tensile strength of at least psi and a elongation of at least See Figure The original thickness of the plate is in The maximum cold work in each step is

a Describe the cold working and annealing steps required to make this product.

b Compare this process with what you would recommend if you could do the initial deformation by hot working.

Figure The effect of percent cold work on the properties of a aluminum alloy

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock