Question: Problem A large milling machine has three different bearings that fail in service. The distribution of the life of each bearing is identical, as shown

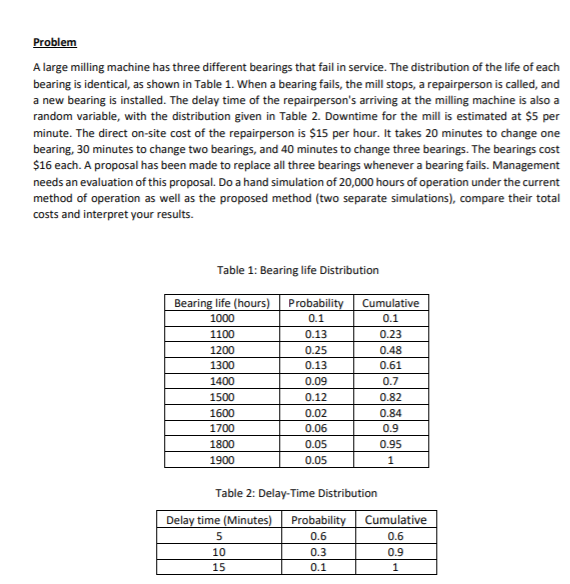

Problem A large milling machine has three different bearings that fail in service. The distribution of the life of each bearing is identical, as shown in Table 1. When a bearing fails, the mill stops, a repairperson is called, and a new bearing is installed. The delay time of the repairperson's arriving at the milling machine is also a random variable, with the distribution given in Table 2. Downtime for the mill is estimated at $5 per minute. The direct on-site cost of the repairperson is $15 per hour. It takes 20 minutes to change one bearing, 30 minutes to change two bearings, and 40 minutes to change three bearings. The bearings cost $16 each. A proposal has been made to replace all three bearings whenever a bearing fails. Management needs an evaluation of this proposal. Do a hand simulation of 20,000 hours of operation under the current method of operation as well as the proposed method (two separate simulations), compare their total costs and interpret your results. Table 1: Bearing life Distribution Cumulative 0.1 Bearing life (hours) Probability 1000 0.1 1100 0.13 1200 0.25 1300 0.13 1400 0.09 1500 0.12 1600 0.02 1700 0.06 1800 0.05 1900 0.05 0.23 0.48 0.61 0.7 0.82 0.84 0.9 0.95 1 Table 2: Delay-Time Distribution Delay time (Minutes) 5 10 15 Probability 0.6 0.3 0.1 Cumulative 0.6 0.9 1 Problem A large milling machine has three different bearings that fail in service. The distribution of the life of each bearing is identical, as shown in Table 1. When a bearing fails, the mill stops, a repairperson is called, and a new bearing is installed. The delay time of the repairperson's arriving at the milling machine is also a random variable, with the distribution given in Table 2. Downtime for the mill is estimated at $5 per minute. The direct on-site cost of the repairperson is $15 per hour. It takes 20 minutes to change one bearing, 30 minutes to change two bearings, and 40 minutes to change three bearings. The bearings cost $16 each. A proposal has been made to replace all three bearings whenever a bearing fails. Management needs an evaluation of this proposal. Do a hand simulation of 20,000 hours of operation under the current method of operation as well as the proposed method (two separate simulations), compare their total costs and interpret your results. Table 1: Bearing life Distribution Cumulative 0.1 Bearing life (hours) Probability 1000 0.1 1100 0.13 1200 0.25 1300 0.13 1400 0.09 1500 0.12 1600 0.02 1700 0.06 1800 0.05 1900 0.05 0.23 0.48 0.61 0.7 0.82 0.84 0.9 0.95 1 Table 2: Delay-Time Distribution Delay time (Minutes) 5 10 15 Probability 0.6 0.3 0.1 Cumulative 0.6 0.9 1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts