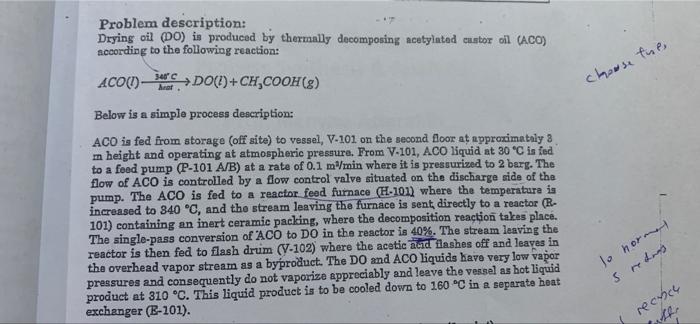

Question: Problem description: Drying oil (0) is produced by thermally decomposing acetylated custor oil (ACC) according to the following reaction: 340 ACO(I) DOC?)+CH COOH () chouse

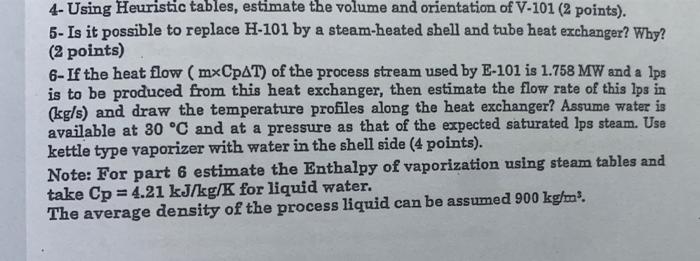

Problem description: Drying oil (0) is produced by thermally decomposing acetylated custor oil (ACC) according to the following reaction: 340" ACO(I) DOC?)+CH COOH () chouse fue Art. Below is a simple process description: ACO is fed from storage (off site) to vessel, V-101 on the second floor at approximately 3 m height and operating at atmospheric pressure. From V-101, ACO liquid at 30 C is fed to a food pump (P-101 A/B) at a rate of 0.1 m/min where it is pressurized to 2 barg. The flow of ACO is controlled by a flow control valve situated on the discharge side of the pump. The ACO is fed to a reactor feed furnace (H-101) where the temperature is increased to 840 C, and the stream leaving the furnace is sent directly to a reactor (B- 101) containing an inert ceramic packing, where the decomposition reaction takes place. The single-pass conversion of ACO to Do in the reactor is 40%. The stream leaving the reactor is then fed to flash drum (V-102) where the acetic nerd ilashes off and leaves in the overhead vapor stream as a byproduct. The DO and ACO liquids have very low vapor pressures and consequently do not vaporize appreciably and leave the vessel as hot liquid product at 310 C. This liquid product is to be cooled down to 160C in a separate heat exchanger (B-101). To hormat s rednas recher 4- Using Heuristic tables, estimate the volume and orientation of V-101 (2 points). 5- Is it possible to replace H-101 by a steam-heated shell and tube heat exchanger? Why? (2 points) 6- If the heat flow (mxCpAT) of the process stream used by E-101 is 1.758 MW and a lps is to be produced from this heat exchanger, then estimate the flow rate of this lps in (kg/s) and draw the temperature profiles along the heat exchanger? Assume water is available at 30 C and at a pressure as that of the expected saturated lps steam. Use kettle type vaporizer with water in the shell side (4 points). Note: For part 6 estimate the Enthalpy of vaporization using steam tables and take Cp = 4.21 kJ/kg/K for liquid water. The average density of the process liquid can be assumed 900 kg/ma

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts