Question: Problem No. 2 Consider a product produced from raw material using a single machine as shown in the figure below. The machine has production rate

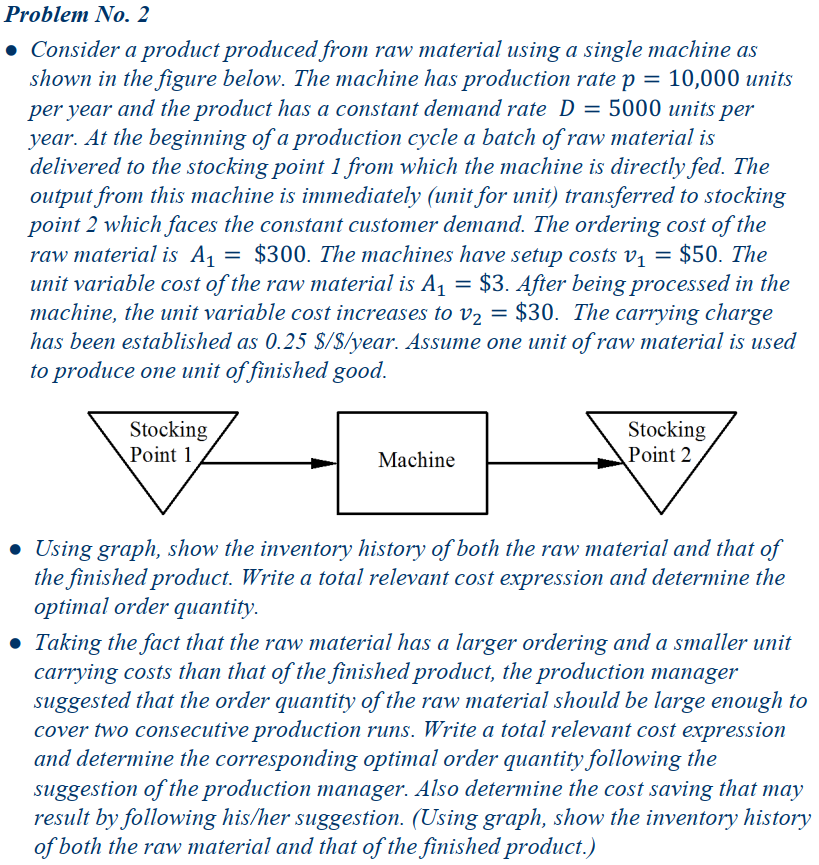

Problem No. 2 Consider a product produced from raw material using a single machine as shown in the figure below. The machine has production rate p - 10,000 units per year and the product has a constant demand rate D- 5000 units per year. At the beginning of a production cycle a batch of raw material is delivered to the stocking point I from which the machine is directly fed. The output from this machine is immediately (unit for unit) transferred to stocking point 2 which faces the constant customer demand. The ordering cost of the raw material is A1$300. The machines have setup costs v1$50. The unit variable cost of the raw material is A1 $3. After being processed in the machine, the unit variable cost increases to v $30. The carrying charge has been established as 0.25 S/Shyear. Assume one unit of raw material is used to produce one unit offinished good Stocking Point 1 Stocking Point 2 Machine Using graph, show the inventory history of both the raw material and that of the finished product. Write a total relevant cost expression and determine the optimal order quantity. Taking the fact that the raw material has a larger ordering and a smaller unit carrying costs than that of the finished product, the production manager suggested that the order quantity of the raw material should be large enough to cover two consecutive production runs. Write a total relevant cost expression and determine the corresponding optimal order quantity following the suggestion of the production manager. Also determine the cost saving that may result by following his/her suggestion. (Using graph, show the inventory history of both the raw material and that of the finished product.) Problem No. 2 Consider a product produced from raw material using a single machine as shown in the figure below. The machine has production rate p - 10,000 units per year and the product has a constant demand rate D- 5000 units per year. At the beginning of a production cycle a batch of raw material is delivered to the stocking point I from which the machine is directly fed. The output from this machine is immediately (unit for unit) transferred to stocking point 2 which faces the constant customer demand. The ordering cost of the raw material is A1$300. The machines have setup costs v1$50. The unit variable cost of the raw material is A1 $3. After being processed in the machine, the unit variable cost increases to v $30. The carrying charge has been established as 0.25 S/Shyear. Assume one unit of raw material is used to produce one unit offinished good Stocking Point 1 Stocking Point 2 Machine Using graph, show the inventory history of both the raw material and that of the finished product. Write a total relevant cost expression and determine the optimal order quantity. Taking the fact that the raw material has a larger ordering and a smaller unit carrying costs than that of the finished product, the production manager suggested that the order quantity of the raw material should be large enough to cover two consecutive production runs. Write a total relevant cost expression and determine the corresponding optimal order quantity following the suggestion of the production manager. Also determine the cost saving that may result by following his/her suggestion. (Using graph, show the inventory history of both the raw material and that of the finished product.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts