Question: Problems Note: Px mears tre problem may be solved with Problems 57.1-57.8 relate to Dupacity - S7.1 Amy Xia's plant was designed to produce 7,000

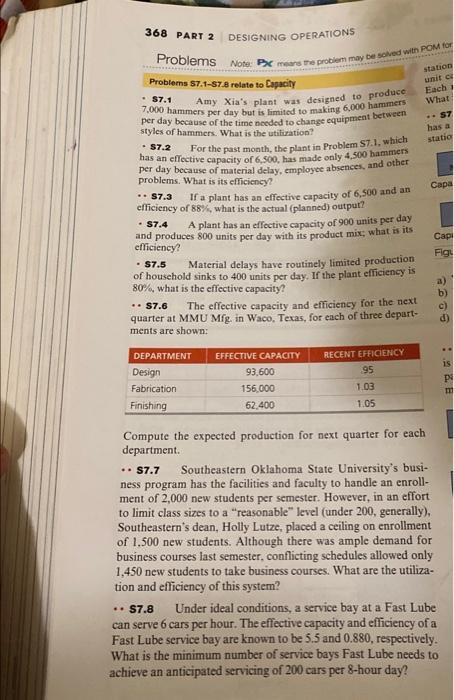

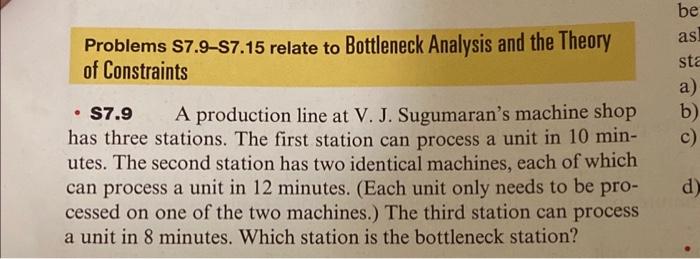

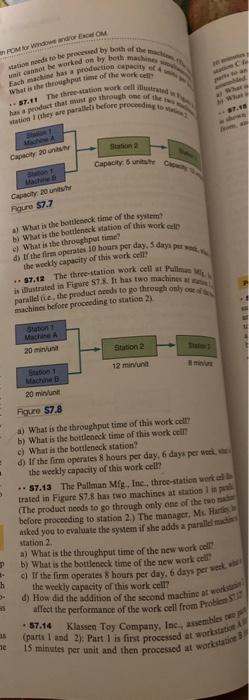

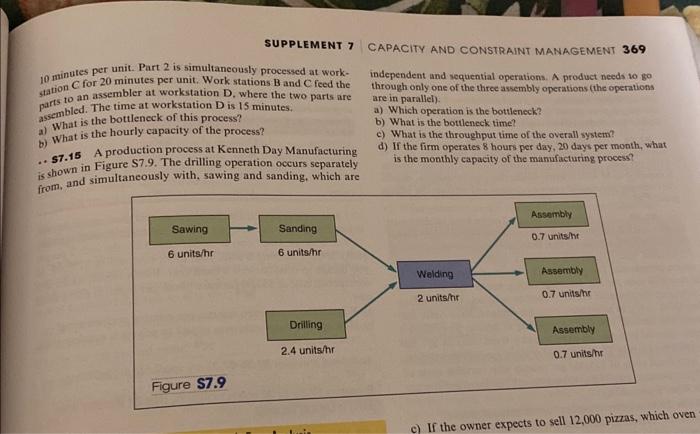

Problems Note: Px mears tre problem may be solved with Problems 57.1-57.8 relate to Dupacity - S7.1 Amy Xia's plant was designed to produce 7,000 hammers per day but is limited to making 6,000 hammers per day because of the time needed to change equipment between styles of hammers. What is the utifitation? - \$7.2 For the past month, the plant in Problem ST.1, which has an effective capacity of 6,500 , has made only 4,500 hammers per day because of material delay, employee absences, and other problems. What is its efficiency? 57.3 If a plant has an effective capacity of 6,500 and an efficiency of 88%, what is the actual (planned) output? - \$7.4 A plant has an effective capacity of 900 units per day and produces 800 units per day with its product mix; what is its efficiency? - 57.5 Material delays have routinely limited production of household sinks to 400 units per day. If the plant efficiency is 80%, what is the effective capacity? . \$7.6 The effective capacity and efficiency for the next quarter at MMU Mfg, in Waco, Texas, for ench of three depurtments are shown: Compute the expected production for next quarter for each department. \$7.7 Southeastern Oklahoma State University's business program has the facilities and faculty to handle an enrollment of 2,000 new students per semester. However, in an effort to limit class sizes to a "reasonable" level (under 200 , generally), Southeastern's dean, Holly Lutze, placed a ceiling on enrollment of 1,500 new students. Although there was ample demand for business courses last semester, conflicting schedules allowed only 1,450 new students to take business courses. What are the utilization and efficiency of this system? . \$7.8 Under ideal conditions, a service bay at a Fast Lube can serve 6 cars per hour. The effective capacity and efficiency of a Fast Lube service bay are known to be 5.5 and 0.880 , respectively. What is the minimum number of service bays Fast Lube needs to Problems S7.9-S7.15 relate to Bottleneck Analysis and the Theory of Constraints - s7.9 A production line at V. J. Sugumaran's machine shop has three stations. The first station can process a unit in 10min utes. The second station has two identical machines, each of which can process a unit in 12 minutes. (Each unit only needs to be processed on one of the two machines.) The third station can process a unit in 8 minutes. Which station is the bottleneck station? SUPPLEMENT 7 CAPACITY AND CONSTRAINT MANAGEMENT 369 10 minutes per unit. Part 2 is simultaneously processed at work- independent and sequential operations. A product needs to go gtation C for 20 minutes per unit. Work stations B and C feed the through only one of the three assembly operations (the operations parts to an assembler at workstation D, where the two parts are are in parallici). assembled. The time at workstation D is 15 minutes. a) What is the bottleneck of this process? a) Which operation is the bottieneck? b) What is the hourly capacity of the process? b) What is the botleneck time? c) What is the throughput time of the overall system? .57.15 A production process at Kenneth Day Manufacturing d) If the firm operates 8 hours per day, 20 days per month, what is shown in Figure S7.9. The drilling operation occurs separately from, and simultaneously with, sawing and sanding, which are is the monthly capacity of the manufacturing process? Problems Note: Px mears tre problem may be solved with Problems 57.1-57.8 relate to Dupacity - S7.1 Amy Xia's plant was designed to produce 7,000 hammers per day but is limited to making 6,000 hammers per day because of the time needed to change equipment between styles of hammers. What is the utifitation? - \$7.2 For the past month, the plant in Problem ST.1, which has an effective capacity of 6,500 , has made only 4,500 hammers per day because of material delay, employee absences, and other problems. What is its efficiency? 57.3 If a plant has an effective capacity of 6,500 and an efficiency of 88%, what is the actual (planned) output? - \$7.4 A plant has an effective capacity of 900 units per day and produces 800 units per day with its product mix; what is its efficiency? - 57.5 Material delays have routinely limited production of household sinks to 400 units per day. If the plant efficiency is 80%, what is the effective capacity? . \$7.6 The effective capacity and efficiency for the next quarter at MMU Mfg, in Waco, Texas, for ench of three depurtments are shown: Compute the expected production for next quarter for each department. \$7.7 Southeastern Oklahoma State University's business program has the facilities and faculty to handle an enrollment of 2,000 new students per semester. However, in an effort to limit class sizes to a "reasonable" level (under 200 , generally), Southeastern's dean, Holly Lutze, placed a ceiling on enrollment of 1,500 new students. Although there was ample demand for business courses last semester, conflicting schedules allowed only 1,450 new students to take business courses. What are the utilization and efficiency of this system? . \$7.8 Under ideal conditions, a service bay at a Fast Lube can serve 6 cars per hour. The effective capacity and efficiency of a Fast Lube service bay are known to be 5.5 and 0.880 , respectively. What is the minimum number of service bays Fast Lube needs to Problems S7.9-S7.15 relate to Bottleneck Analysis and the Theory of Constraints - s7.9 A production line at V. J. Sugumaran's machine shop has three stations. The first station can process a unit in 10min utes. The second station has two identical machines, each of which can process a unit in 12 minutes. (Each unit only needs to be processed on one of the two machines.) The third station can process a unit in 8 minutes. Which station is the bottleneck station? SUPPLEMENT 7 CAPACITY AND CONSTRAINT MANAGEMENT 369 10 minutes per unit. Part 2 is simultaneously processed at work- independent and sequential operations. A product needs to go gtation C for 20 minutes per unit. Work stations B and C feed the through only one of the three assembly operations (the operations parts to an assembler at workstation D, where the two parts are are in parallici). assembled. The time at workstation D is 15 minutes. a) What is the bottleneck of this process? a) Which operation is the bottieneck? b) What is the hourly capacity of the process? b) What is the botleneck time? c) What is the throughput time of the overall system? .57.15 A production process at Kenneth Day Manufacturing d) If the firm operates 8 hours per day, 20 days per month, what is shown in Figure S7.9. The drilling operation occurs separately from, and simultaneously with, sawing and sanding, which are is the monthly capacity of the manufacturing process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts