Question: process 1 2 3 use Maxi-Min programming to formulate problem (25 pts) A factory manufacturer produces a specialized product. Each unit of the product

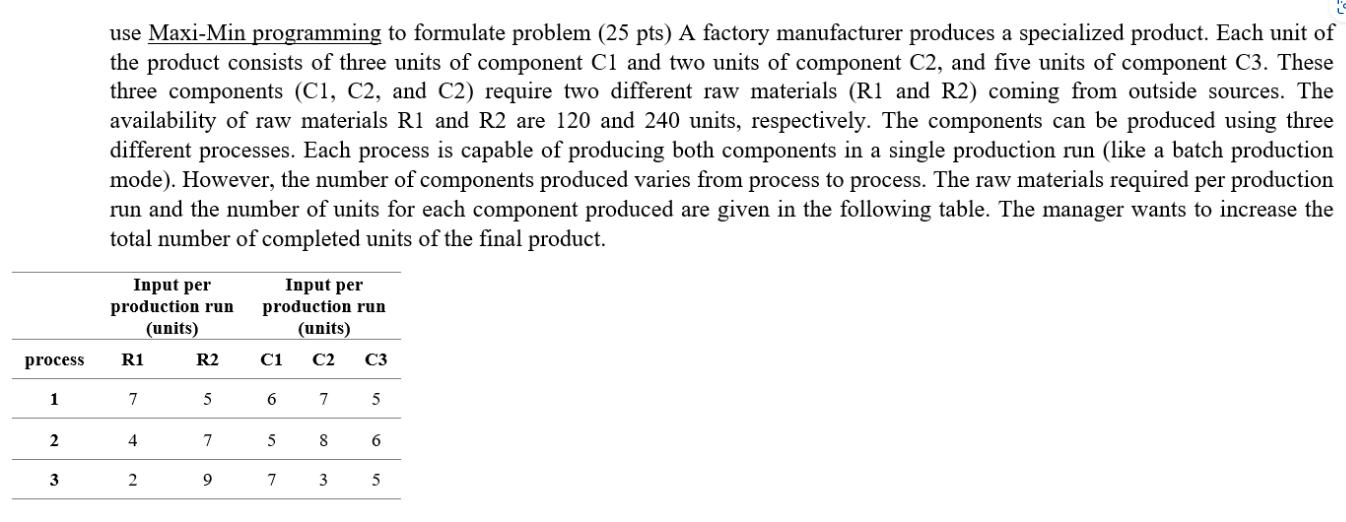

process 1 2 3 use Maxi-Min programming to formulate problem (25 pts) A factory manufacturer produces a specialized product. Each unit of the product consists of three units of component C1 and two units of component C2, and five units of component C3. These three components (C1, C2, and C2) require two different raw materials (R1 and R2) coming from outside sources. The availability of raw materials R1 and R2 are 120 and 240 units, respectively. The components can be produced using three different processes. Each process is capable of producing both components in a single production run (like a batch production mode). However, the number of components produced varies from process to process. The raw materials required per production run and the number of units for each component produced are given in the following table. The manager wants to increase the total number of completed units of the final product. Input per production run (units) R1 7 4 2 R2 5 7 9 Input per production run (units) C1 6 5 7 C2 C3 7 8 3 5 6 5

Step by Step Solution

3.52 Rating (155 Votes )

There are 3 Steps involved in it

Solution Here is the MaxiMin formulation for this production planning problem Sets P set of produc... View full answer

Get step-by-step solutions from verified subject matter experts