Question: Process Activity Analysis Brite Beverage Company bottles soft drinks into aluminum cans. The manufacturing process consists of three activities: 1. Mixing: water, sugar, and beverage

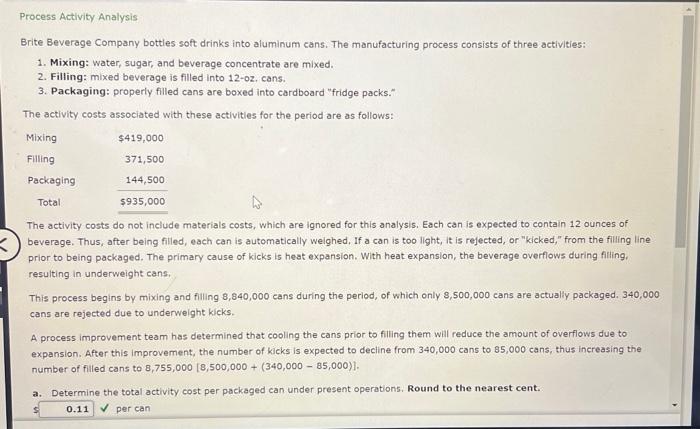

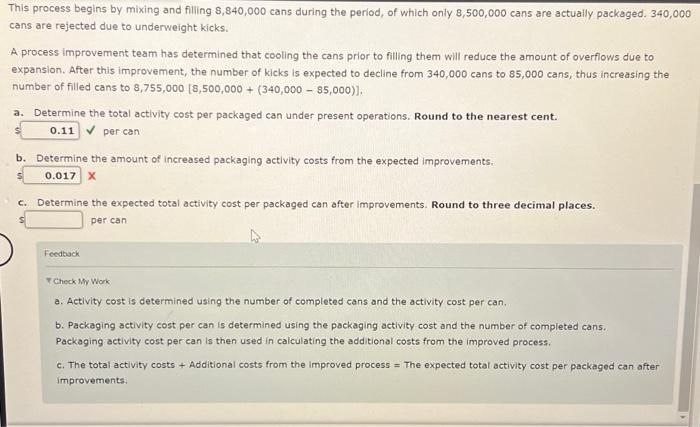

Process Activity Analysis Brite Beverage Company bottles soft drinks into aluminum cans. The manufacturing process consists of three activities: 1. Mixing: water, sugar, and beverage concentrate are mixed. 2. Filling: mixed beverage is filled into 120z, cans. 3. Packaging: properly flled cans are boxed into cardboard "fridge packs." The activity costs associated with these activities for the period are as follows: The activity costs do not include materials costs, which are ignored for this analysis. Each can is expected to contain 12 ounces of beverage. Thus, after being filled, each can is automatically welghed, If a can is too light, it is rejected, or "kicked," from the filling line prior to being packaged. The primary cause of kicks is heat expansion. With heat expansion, the beverage overflows during filling. resulting in underweight cans. This process begins by mixing and filling 8,840,000 cans during the period, of which only 8,500,000 cans are actually packaged. 340,000 cans are rejected due to underweight kicks. A process improvement team has determined that cooling the cans prior to filling them will reduce the amount of overflows due to expansion. After this improvement, the number of kicks is expected to decline from 340,000 cans to 85,000 cans, thus increasing the number of filled cans to 8,755,000[8,500,000+(340,00085,000)]. a. Determine the total activity cost per packaged can under present operations. Round to the nearest cent. s per can This process begins by mixing and filling 8,840,000 cans during the period, of which only 8,500,000 cans are actually packaged. 340,000 cans are rejected due to underweight kicks. A process improvement team has determined that cooling the cans prior to filling them will reduce the amount of overflows due to expansion. After this improvement, the number of kicks is expected to decline from 340,000 cans to 85,000 cans, thus increasing the number of filled cans to 8,755,000[8,500,000+(340,00085,000)]. a. Determine the total activity cost per packaged can under present operations. Round to the nearest cent. percan b. Determine the amount of increased packaging activity costs from the expected improvements. x c. Determine the expected total activity cost per packaged can efter improvements. Round to three decimal places. s. percan Feedback Theck My Work a. Activity cost is determined using the number of completed cans and the activity cost per can. b. Packaging activity cost per can is determined using the packaging activity cost and the number of completed cans. Packaging activity cost per can is then used in calculating the additional costs from the improved process. c. The total activity costs + Additional costs from the improved process = The expected total activity cost per packaged can after improvements

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts