Question: Processing often requires that alloys be annealed so that the variations in composition can be smoothed out by atomic diffusion. Consider an alloy of

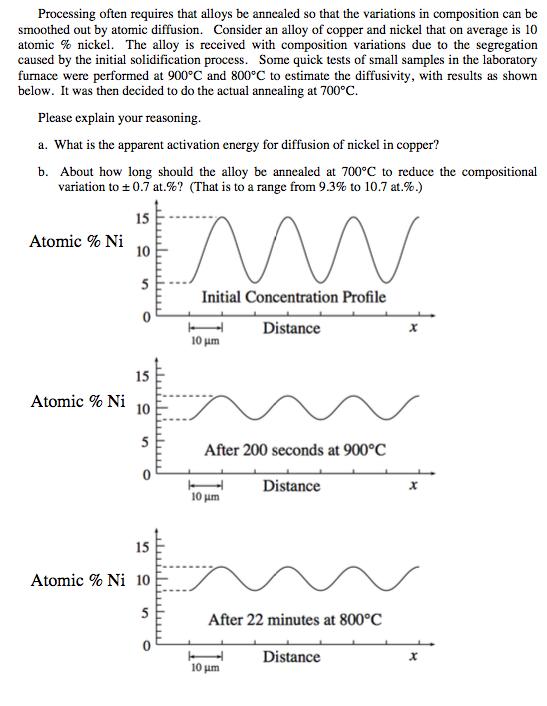

Processing often requires that alloys be annealed so that the variations in composition can be smoothed out by atomic diffusion. Consider an alloy of copper and nickel that on average is 10 atomic % nickel. The alloy is received with composition variations due to the segregation caused by the initial solidification process. Some quick tests of small samples in the laboratory furnace were performed at 900C and 800C to estimate the diffusivity, with results as shown below. It was then decided to do the actual annealing at 700C. Please explain your reasoning. a. What is the apparent activation energy for diffusion of nickel in copper? b. About how long should the alloy be annealed at 700C to reduce the compositional variation to 0.7 at.%? (That is to a range from 9.3% to 10.7 at.%.) 15 Atomic % Ni Atomic % Ni 10 5 15 10 O 15 Atomic % Ni 10 5 m Initial Concentration Profile Distance 10 m After 200 seconds at 900C Distance 10 m After 22 minutes at 800C 10 m. Distance X

Step by Step Solution

3.36 Rating (152 Votes )

There are 3 Steps involved in it

Answer b a Answer Quick dests of small samples in the lab wure Appar... View full answer

Get step-by-step solutions from verified subject matter experts