Question: Products A, B, C, D and E require the same processing facility for their manufacture. At any one time, therefore, this facility can produce only

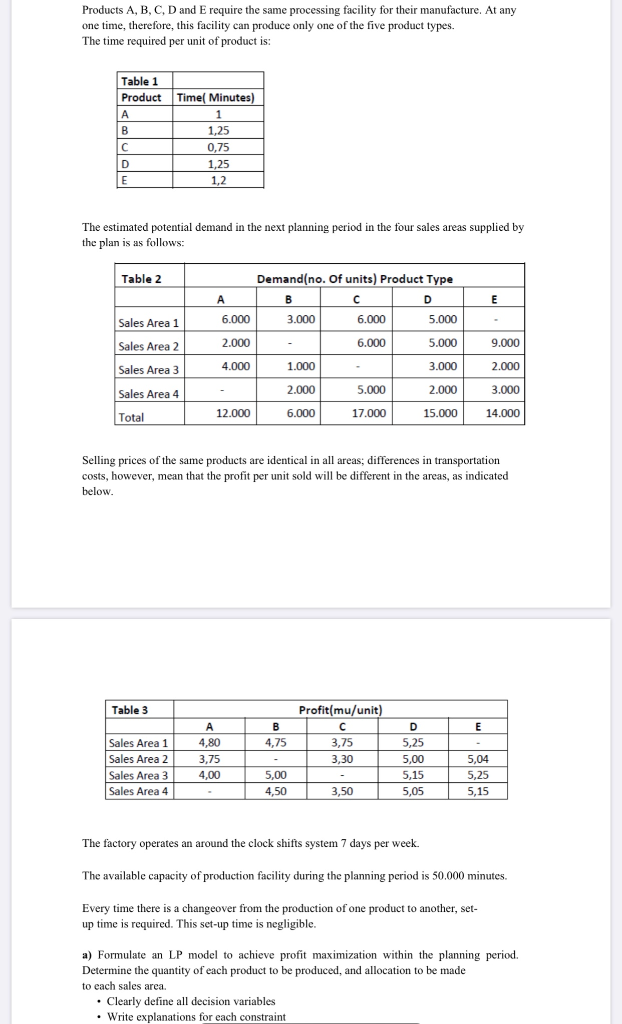

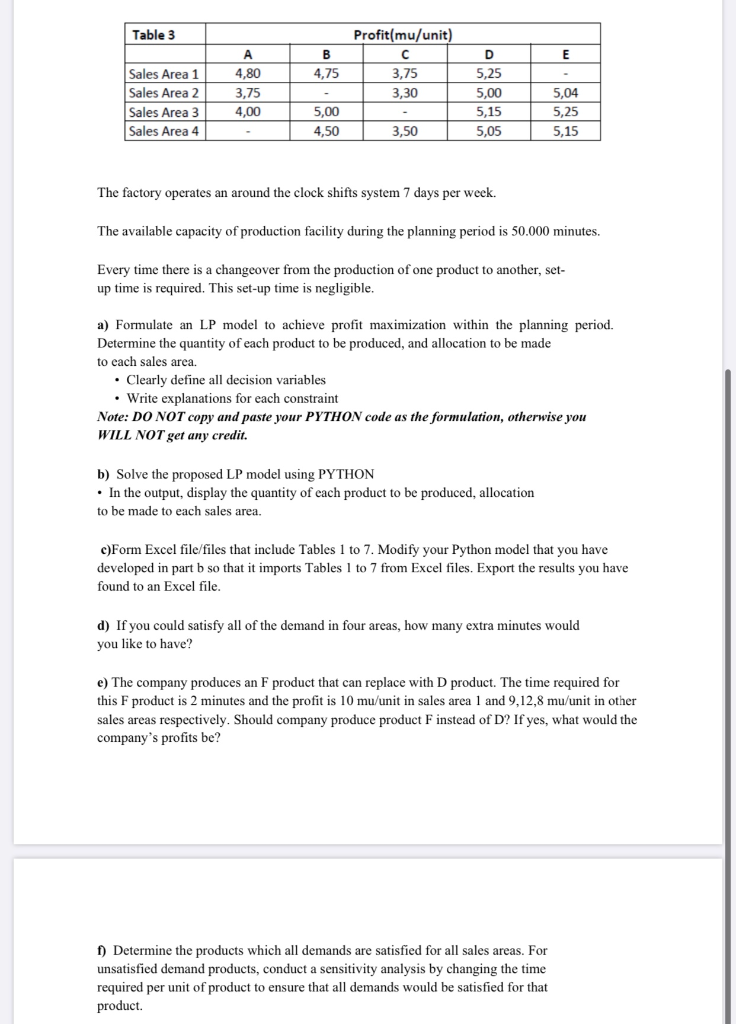

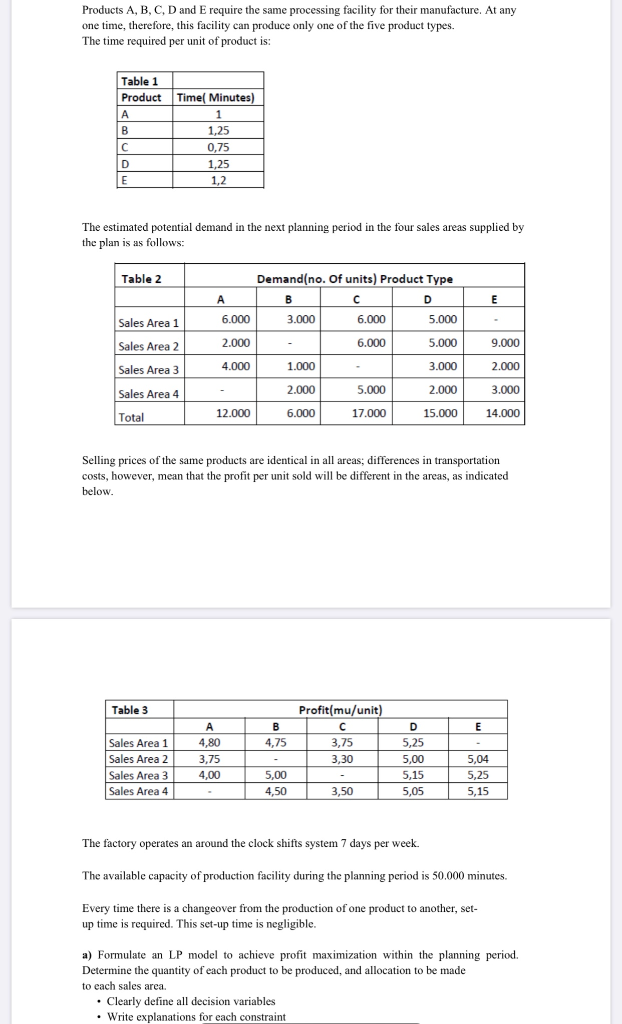

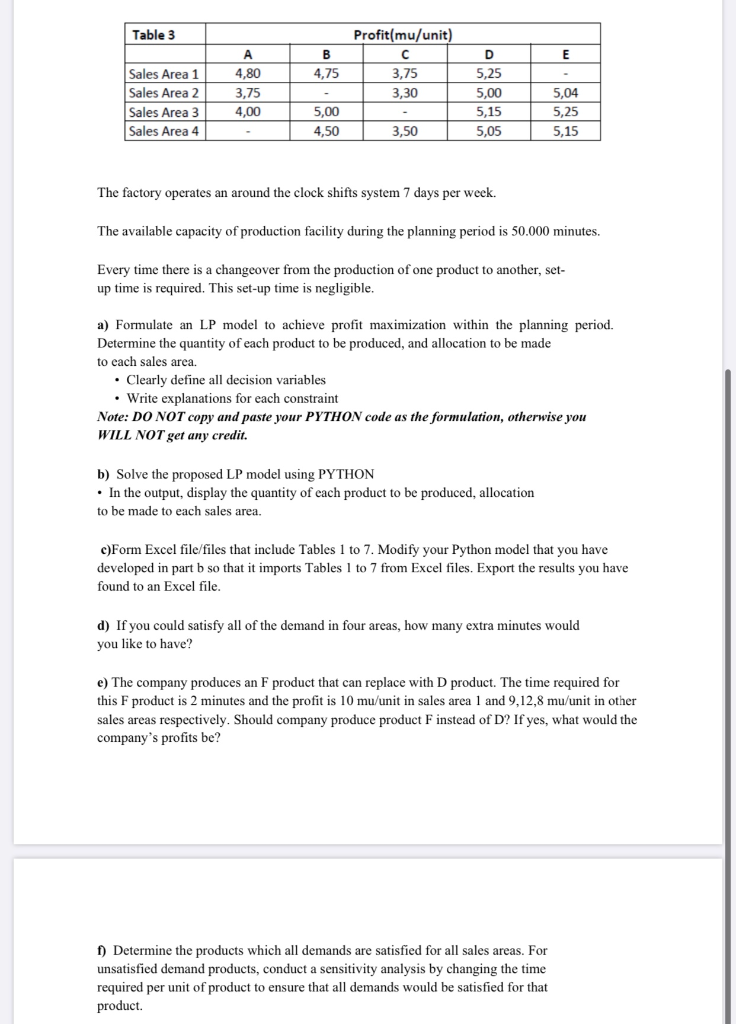

Products A, B, C, D and E require the same processing facility for their manufacture. At any one time, therefore, this facility can produce only one of the five product types. The time required per unit of product is: Table 1 Product Time Minutes) 1,25 0,75 1,25 1,2 The estimated potential demand in the next planning period in the four sales areas supplied by the plan is as follows: Table 2 Demand(no. Of units) Product Type 3.000 Sales Area 1 Sales Area 2 Sales Area 3 6.000 6.000 6.000 2.000 4.000 - 12.000 5.000 5.000 3.000 2.000 15.000 1.000 2.000 6.000 9.000 2.000 3.000 14.000 Sales Area 4 5.000 17.000 Total Selling prices of the same products are identical in all areas, differences in transportation costs, however, mean that the profit per unit sold will be different in the areas, as indicated below. Table 3 Sales Area 1 Sales Area 2 Sales Area 3 Sales Area 4 Profit(mu/unit) AB 4,80 4.75 3,75 3,75 3.30 4 ,00 5.00 4,50 3.50 5,05 The factory operates an around the clock shifts system 7 days per week. The available capacity of production facility during the planning period is 50.000 minutes. Every time there is a changeover from the production of one product to another, set- up time is required. This set-up time is negligible. a) Formulate an LP model to achieve profit maximization within the planning period. Determine the quantity of each product to be produced, and allocation to be made to each sales area. Clearly define all decision variables Write explanations for each constraint Table 3 Profit(mu/unit) 4,80 4,75 3. Sales Area 1 Sales Area 2 Sales Area 3 Sales Area 4 3,75 13,305,00 5,155 3,50 5,05 4 ,00 - ,25 5,15 1 4,50 The factory operates an around the clock shifts system 7 days per week. The available capacity of production facility during the planning period is 50.000 minutes. Every time there is a changeover from the production of one product to another, set- up time is required. This set-up time is negligible. a) Formulate an LP model to achieve profit maximization within the planning period. Determine the quantity of each product to be produced, and allocation to be made to each sales area. Clearly define all decision variables Write explanations for each constraint Note: DO NOT copy and paste your PYTHON code as the formulation, otherwise you WILL NOT get any credit. b) Solve the proposed LP model using PYTHON In the output, display the quantity of each product to be produced, allocation to be made to each sales area. c)Form Excel file/files that include Tables 1 to 7. Modify your Python model that you have developed in part b so that it imports Tables 1 to 7 from Excel files. Export the results you have found to an Excel file. d) If you could satisfy all of the demand in four areas, how many extra minutes would you like to have? e) The company produces an F product that can replace with D product. The time required for this F product is 2 minutes and the profit is 10 mu/unit in sales area 1 and 9,12,8 mu/unit in other sales areas respectively. Should company produce product F instead of D? If yes, what would the company's profits be? 1) Determine the products which all demands are satisfied for all sales areas. For unsatisfied demand products, conduct a sensitivity analysis by changing the time required per unit of product to ensure that all demands would be satisfied for that product. Products A, B, C, D and E require the same processing facility for their manufacture. At any one time, therefore, this facility can produce only one of the five product types. The time required per unit of product is: Table 1 Product Time Minutes) 1,25 0,75 1,25 1,2 The estimated potential demand in the next planning period in the four sales areas supplied by the plan is as follows: Table 2 Demand(no. Of units) Product Type 3.000 Sales Area 1 Sales Area 2 Sales Area 3 6.000 6.000 6.000 2.000 4.000 - 12.000 5.000 5.000 3.000 2.000 15.000 1.000 2.000 6.000 9.000 2.000 3.000 14.000 Sales Area 4 5.000 17.000 Total Selling prices of the same products are identical in all areas, differences in transportation costs, however, mean that the profit per unit sold will be different in the areas, as indicated below. Table 3 Sales Area 1 Sales Area 2 Sales Area 3 Sales Area 4 Profit(mu/unit) AB 4,80 4.75 3,75 3,75 3.30 4 ,00 5.00 4,50 3.50 5,05 The factory operates an around the clock shifts system 7 days per week. The available capacity of production facility during the planning period is 50.000 minutes. Every time there is a changeover from the production of one product to another, set- up time is required. This set-up time is negligible. a) Formulate an LP model to achieve profit maximization within the planning period. Determine the quantity of each product to be produced, and allocation to be made to each sales area. Clearly define all decision variables Write explanations for each constraint Table 3 Profit(mu/unit) 4,80 4,75 3. Sales Area 1 Sales Area 2 Sales Area 3 Sales Area 4 3,75 13,305,00 5,155 3,50 5,05 4 ,00 - ,25 5,15 1 4,50 The factory operates an around the clock shifts system 7 days per week. The available capacity of production facility during the planning period is 50.000 minutes. Every time there is a changeover from the production of one product to another, set- up time is required. This set-up time is negligible. a) Formulate an LP model to achieve profit maximization within the planning period. Determine the quantity of each product to be produced, and allocation to be made to each sales area. Clearly define all decision variables Write explanations for each constraint Note: DO NOT copy and paste your PYTHON code as the formulation, otherwise you WILL NOT get any credit. b) Solve the proposed LP model using PYTHON In the output, display the quantity of each product to be produced, allocation to be made to each sales area. c)Form Excel file/files that include Tables 1 to 7. Modify your Python model that you have developed in part b so that it imports Tables 1 to 7 from Excel files. Export the results you have found to an Excel file. d) If you could satisfy all of the demand in four areas, how many extra minutes would you like to have? e) The company produces an F product that can replace with D product. The time required for this F product is 2 minutes and the profit is 10 mu/unit in sales area 1 and 9,12,8 mu/unit in other sales areas respectively. Should company produce product F instead of D? If yes, what would the company's profits be? 1) Determine the products which all demands are satisfied for all sales areas. For unsatisfied demand products, conduct a sensitivity analysis by changing the time required per unit of product to ensure that all demands would be satisfied for that product