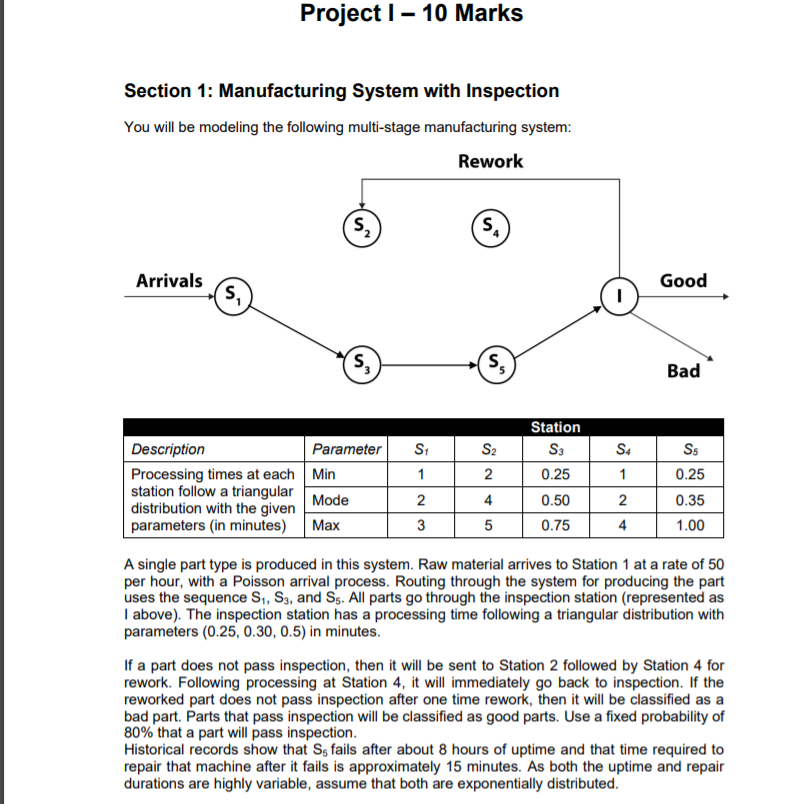

Question: Project | - 10 Marks Section 1: Manufacturing System with Inspection You will be modeling the following multi-stage manufacturing system: Rework sz $). Arrivals Good

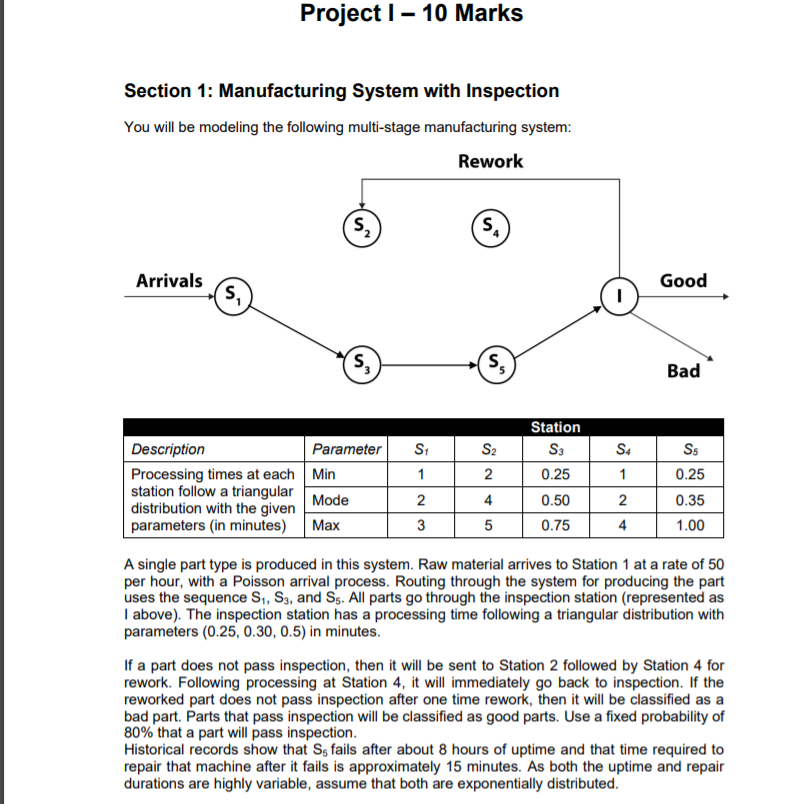

Project | - 10 Marks Section 1: Manufacturing System with Inspection You will be modeling the following multi-stage manufacturing system: Rework sz $). Arrivals Good s, 1 sz s, Bad S. S1 1 S2 2 Station S3 0.25 0.50 0.75 Ss 0.25 Description Parameter Processing times at each Min station follow a triangular distribution with the given Mode parameters (in minutes) Max 1 2 4 5 2 4 0.35 1.00 3 A single part type is produced in this system. Raw material arrives to Station 1 at a rate of 50 per hour, with a Poisson arrival process. Routing through the system for producing the part uses the sequence S1, S3, and Ss. All parts go through the inspection station (represented as | above). The inspection station has a processing time following a triangular distribution with parameters (0.25, 0.30, 0.5) in minutes. If a part does not pass inspection, then it will be sent to Station 2 followed by Station 4 for rework. Following processing at Station 4, it will immediately go back to inspection. If the reworked part does not pass inspection after one time rework, then it will be classified as a bad part. Parts that pass inspection will be classified as good parts. Use a fixed probability of 80% that a part will pass inspection Historical records show that Ss fails after about 8 hours of uptime and that time required to repair that machine after it fails is approximately 15 minutes. As both the uptime and repair durations are highly variable, assume that both are exponentially distributed. Project | - 10 Marks Section 1: Manufacturing System with Inspection You will be modeling the following multi-stage manufacturing system: Rework sz $). Arrivals Good s, 1 sz s, Bad S. S1 1 S2 2 Station S3 0.25 0.50 0.75 Ss 0.25 Description Parameter Processing times at each Min station follow a triangular distribution with the given Mode parameters (in minutes) Max 1 2 4 5 2 4 0.35 1.00 3 A single part type is produced in this system. Raw material arrives to Station 1 at a rate of 50 per hour, with a Poisson arrival process. Routing through the system for producing the part uses the sequence S1, S3, and Ss. All parts go through the inspection station (represented as | above). The inspection station has a processing time following a triangular distribution with parameters (0.25, 0.30, 0.5) in minutes. If a part does not pass inspection, then it will be sent to Station 2 followed by Station 4 for rework. Following processing at Station 4, it will immediately go back to inspection. If the reworked part does not pass inspection after one time rework, then it will be classified as a bad part. Parts that pass inspection will be classified as good parts. Use a fixed probability of 80% that a part will pass inspection Historical records show that Ss fails after about 8 hours of uptime and that time required to repair that machine after it fails is approximately 15 minutes. As both the uptime and repair durations are highly variable, assume that both are exponentially distributed