Question: Project Assignment: COMPLETE TASK # 2 FOR ONLY 1 - 1 SHELL AND TUBE HEAT EXCHANGERS You are a Design Engineer at the petrochemical manufacturing

Project Assignment:

COMPLETE TASK # FOR ONLY SHELL AND TUBE HEAT EXCHANGERS

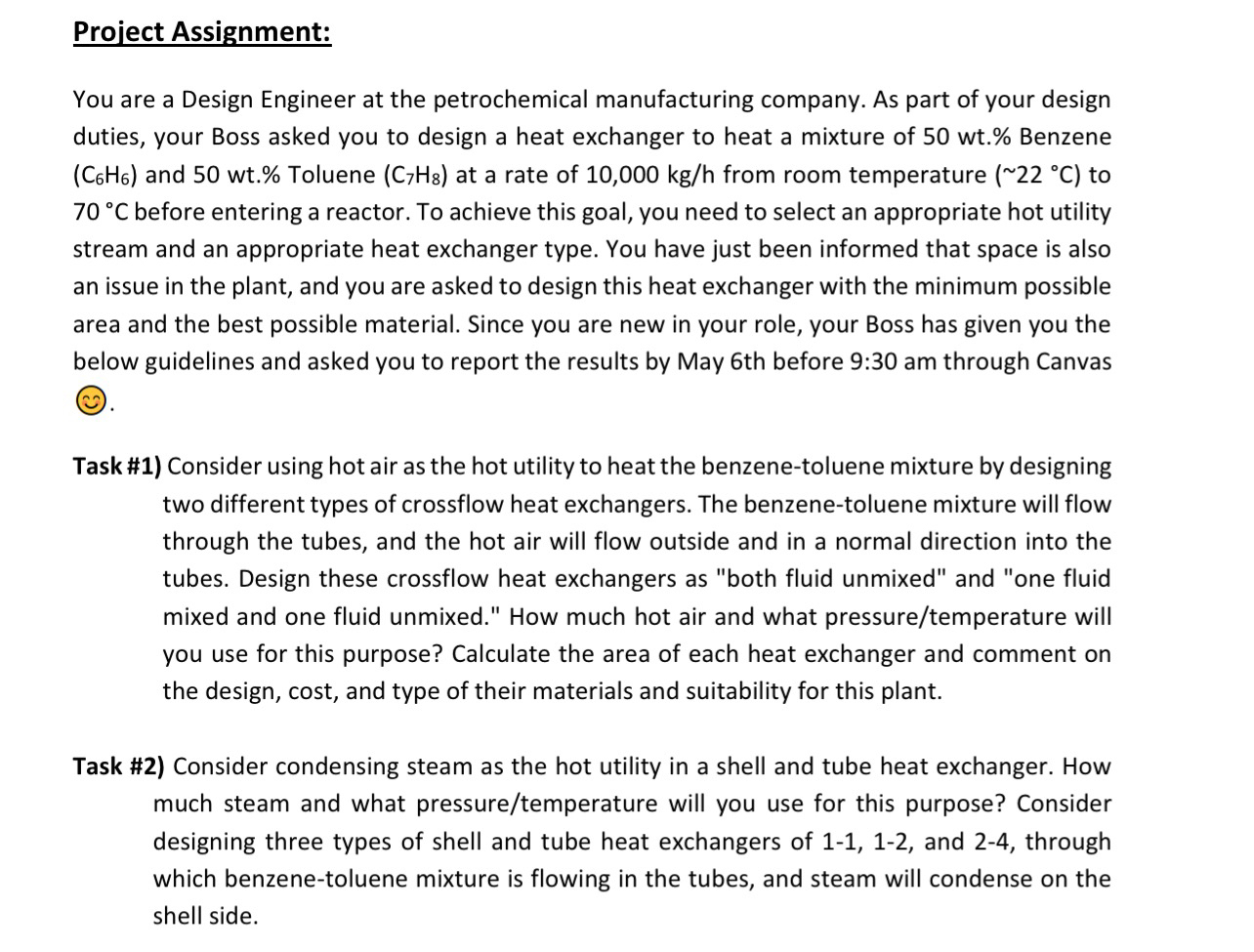

You are a Design Engineer at the petrochemical manufacturing company. As part of your design duties, your Boss asked you to design a heat exchanger to heat a mixture of Benzene and To luene at a rate of from room temperature to before entering a reactor. To achieve this goal, you need to select an appropriate hot utility stream and an appropriate heat exchanger type. You have just been informed that space is also an issue in the plant, and you are asked to design this heat exchanger with the minimum possible area and the best possible material. Since you are new in your role, your Boss has given you the below guidelines and asked you to report the results by May Th

Task # Consider condensing steam as the hot utility in a shell and tube heat exchanger. How much steam and what pressuretemperature will you use for this purpose? Consider designing three types of shell and tube heat exchangers of and through which benzenetoluene mixture is flowing in the tubes, and steam will condense on the shell side.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock