Question: Project description A typical multivariable control problem in the figure below is to be considered as a case study in this project. Namely, the control

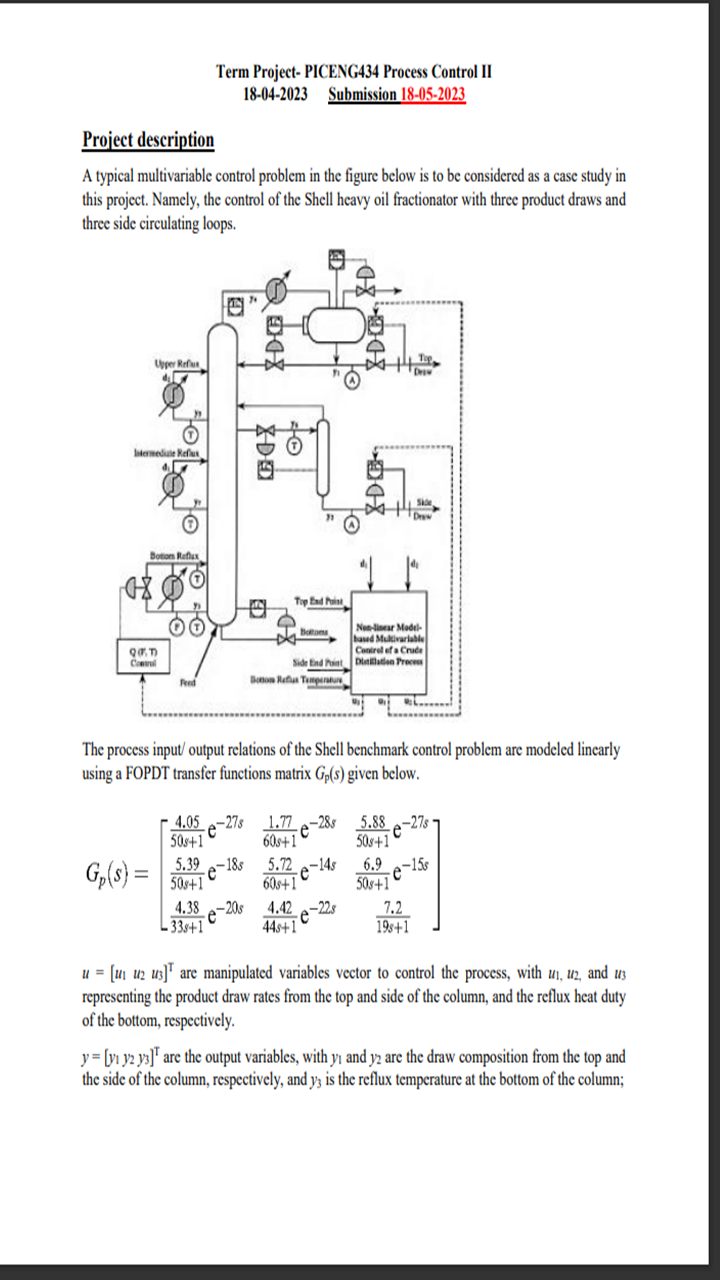

Project description A typical multivariable control problem in the figure below is to be considered as a case study in this project. Namely, the control of the Shell heavy oil fractionator with three product draws and three side circulating loops. The process input/ output relations of the Shell benchmark control problem are modeled linearly using a FOPDT transfer functions matrix Gp(s) given below. Gp(s)=50s+14.05e27s50s+15.39e18s33s+14.38e20s60s+11.77e28s60s+15.72e14s44s+14.42e22s50s+15.88e27s50s+16.9e15s19s+17.2 u=[u1u2u3] are manipulated variables vector to control the process, with u1,u2, and u3 representing the product draw rates from the top and side of the column, and the reflux heat duty of the bottom, respectively. y=[y1y2y3] are the output variables, with y1 and y2 are the draw composition from the top and the side of the column, respectively, and y3 is the reflux temperature at the bottom of the column; Project task: A. Suggest a control pairing for the process if three single-loop controllers are to be used, and verify your suggestion using the Niederlinski Index (NI) and the Condition number (CN). B. Design a multi-loop PI controller for this process based on your recommendation from part (a). Use an appropriate tuning approach for the controllers. C. Design a steady-state de-coupler; simulate the closed-loop system response to a unit step change in the y1 set-point (no set-point change in y2 and y3.) D. Obtain the closed loop system response to a unit change in the y1 set point. Plot the responses of the input as well as the output variables for Parts (B) and (C). E. Design an MPC controller using MATLAB/Simulink and evaluate the performance for the same set point change as in part (D). Use appropriate tuning parameters for the MPC. Plot the responses of the input as well as the output variables. Note that the controllers' performance evaluation should be carried out using criteria such as settling time, overshoot, oscillations, etc. Project report Produce a concise report detailing your procedure, design, calculations, graphs, results, analysis and, discussion. - Title - Abstract - Introduction - Block diagram representation - Controller design and implementation (PI and MPC) - Simulation and results discussion - Conclusion and recommendation - References SIMULINK file is to be submitted as well. Project description A typical multivariable control problem in the figure below is to be considered as a case study in this project. Namely, the control of the Shell heavy oil fractionator with three product draws and three side circulating loops. The process input/ output relations of the Shell benchmark control problem are modeled linearly using a FOPDT transfer functions matrix Gp(s) given below. Gp(s)=50s+14.05e27s50s+15.39e18s33s+14.38e20s60s+11.77e28s60s+15.72e14s44s+14.42e22s50s+15.88e27s50s+16.9e15s19s+17.2 u=[u1u2u3] are manipulated variables vector to control the process, with u1,u2, and u3 representing the product draw rates from the top and side of the column, and the reflux heat duty of the bottom, respectively. y=[y1y2y3] are the output variables, with y1 and y2 are the draw composition from the top and the side of the column, respectively, and y3 is the reflux temperature at the bottom of the column; Project task: A. Suggest a control pairing for the process if three single-loop controllers are to be used, and verify your suggestion using the Niederlinski Index (NI) and the Condition number (CN). B. Design a multi-loop PI controller for this process based on your recommendation from part (a). Use an appropriate tuning approach for the controllers. C. Design a steady-state de-coupler; simulate the closed-loop system response to a unit step change in the y1 set-point (no set-point change in y2 and y3.) D. Obtain the closed loop system response to a unit change in the y1 set point. Plot the responses of the input as well as the output variables for Parts (B) and (C). E. Design an MPC controller using MATLAB/Simulink and evaluate the performance for the same set point change as in part (D). Use appropriate tuning parameters for the MPC. Plot the responses of the input as well as the output variables. Note that the controllers' performance evaluation should be carried out using criteria such as settling time, overshoot, oscillations, etc. Project report Produce a concise report detailing your procedure, design, calculations, graphs, results, analysis and, discussion. - Title - Abstract - Introduction - Block diagram representation - Controller design and implementation (PI and MPC) - Simulation and results discussion - Conclusion and recommendation - References SIMULINK file is to be submitted as well

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts