Question: Provide Source code of ABAQUS Model .jnl file Consider the following composite structure with the dimensions illustrated below: 5 inch 1.18 in Width=2 in 13

Provide Source code of ABAQUS Model .jnl file

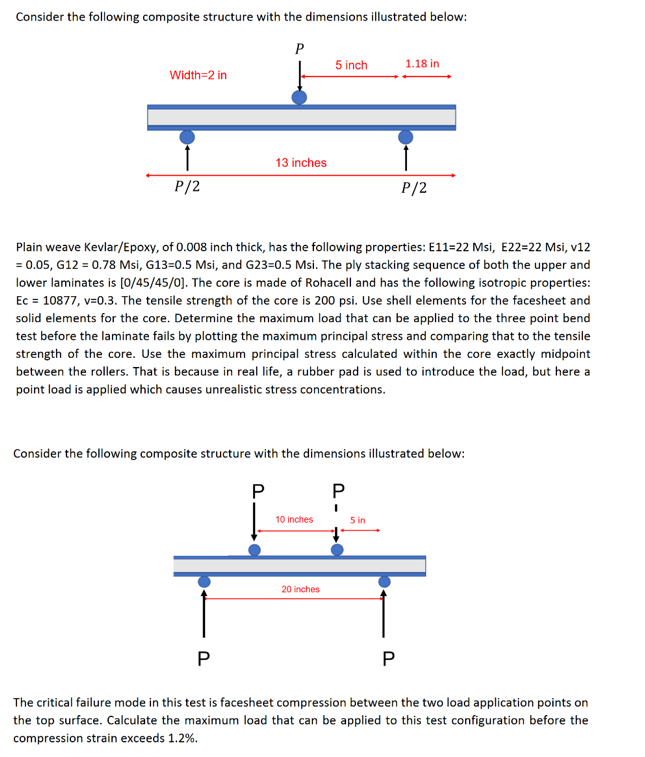

Consider the following composite structure with the dimensions illustrated below: 5 inch 1.18 in Width=2 in 13 inches P/2 P/2 Plain weave Kevlar/Epoxy, of 0.008 inch thick, has the following properties: E11-22 Msi, E22=22 Msi, v12 = 0.05, G12 = 0.78 Msi, G13=0.5 Msi, and G23=0.5 Msi. The ply stacking sequence of both the upper and lower laminates is [0/45/45/0). The core is made of Rohacell and has the following isotropic properties: Ec = 10877, v=0.3. The tensile strength of the core is 200 psi. Use shell elements for the facesheet and solid elements for the core. Determine the maximum load that can be applied to the three point bend test before the laminate fails by plotting the maximum principal stress and comparing that to the tensile strength of the core. Use the maximum principal stress calculated within the core exactly midpoint between the rollers. That is because in real life, a rubber pad is used to introduce the load, but here a point load is applied which causes unrealistic stress concentrations. Consider the following composite structure with the dimensions illustrated below: P 1 10 inches 5 in 20 inches The critical failure mode in this test is facesheet compression between the two load application points on the top surface. Calculate the maximum load that can be applied to this test configuration before the compression strain exceeds 1.2%. Consider the following composite structure with the dimensions illustrated below: 5 inch 1.18 in Width=2 in 13 inches P/2 P/2 Plain weave Kevlar/Epoxy, of 0.008 inch thick, has the following properties: E11-22 Msi, E22=22 Msi, v12 = 0.05, G12 = 0.78 Msi, G13=0.5 Msi, and G23=0.5 Msi. The ply stacking sequence of both the upper and lower laminates is [0/45/45/0). The core is made of Rohacell and has the following isotropic properties: Ec = 10877, v=0.3. The tensile strength of the core is 200 psi. Use shell elements for the facesheet and solid elements for the core. Determine the maximum load that can be applied to the three point bend test before the laminate fails by plotting the maximum principal stress and comparing that to the tensile strength of the core. Use the maximum principal stress calculated within the core exactly midpoint between the rollers. That is because in real life, a rubber pad is used to introduce the load, but here a point load is applied which causes unrealistic stress concentrations. Consider the following composite structure with the dimensions illustrated below: P 1 10 inches 5 in 20 inches The critical failure mode in this test is facesheet compression between the two load application points on the top surface. Calculate the maximum load that can be applied to this test configuration before the compression strain exceeds 1.2%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts