Question: Q 1 . In an orthogonal turning process, a turning tool is assumed to be more flexible than the Aluminum workpiece with a normal cutting

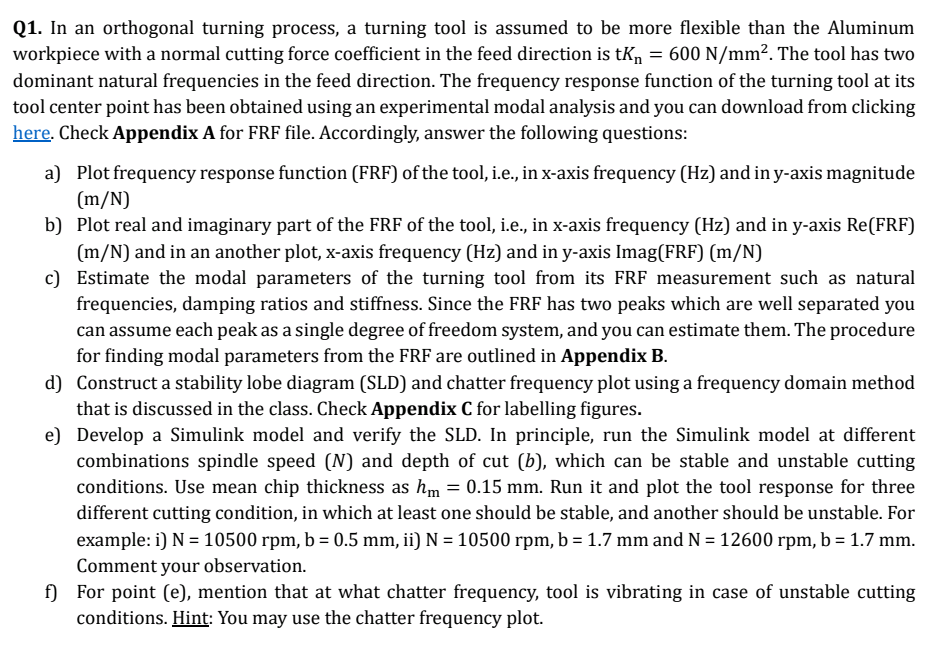

Q In an orthogonal turning process, a turning tool is assumed to be more flexible than the Aluminum workpiece with a normal cutting force coefficient in the feed direction is The tool has two dominant natural frequencies in the feed direction. The frequency response function of the turning tool at its tool center point has been obtained using an experimental modal analysis and you can download from clicking here. Check Appendix A for FRF file. Accordingly, answer the following questions:

a Plot frequency response function FRF of the tool, ie in axis frequency and in axis magnitude

b Plot real and imaginary part of the FRF of the tool, ie in axis frequency Hz and in y axis and in an another plot, x axis frequency Hz and in y axis Imag

c Estimate the modal parameters of the turning tool from its FRF measurement such as natural frequencies, damping ratios and stiffness. Since the FRF has two peaks which are well separated you can assume each peak as a single degree of freedom system, and you can estimate them. The procedure for finding modal parameters from the FRF are outlined in Appendix B

d Construct a stability lobe diagram SLD and chatter frequency plot using a frequency domain method that is discussed in the class. Check Appendix C for labelling figures.

e Develop a Simulink model and verify the SLD In principle, run the Simulink model at different combinations spindle speed and depth of cut b which can be stable and unstable cutting conditions. Use mean chip thickness as Run it and plot the tool response for three different cutting condition, in which at least one should be stable, and another should be unstable. For example: i ii and Comment your observation.

f For point e mention that at what chatter frequency, tool is vibrating in case of unstable cutting conditions. Hint: You may use the chatter frequency plot.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock