Question: Q. A production manager is making a decision on batch size for a product with an annual demand of 25,000 units per year. The setup

Q. A production manager is making a decision on batch size for a product with an annual demand of 25,000 units per year. The setup cost for each batch is $45 and once the setup is complete, the product may be produced at the rate of 650 units per day. There is a holding cost of $2 per unit per year and the plant operates on a 250-day production year.

a) How big should the production batch be; and

b) How long (in days) will it take to produce the batch?

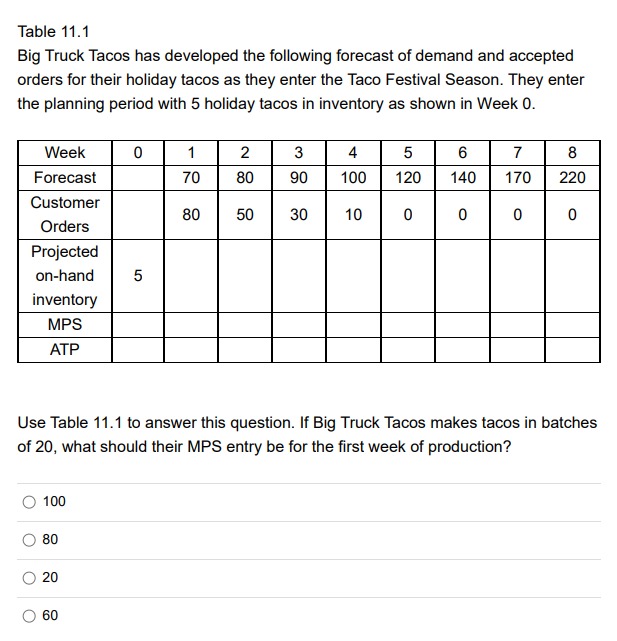

Table 11.1 Big Truck Tacos has developed the following forecast of demand and accepted orders for their holiday tacos as they enter the Taco Festival Season. They enter the planning period with 5 holiday tacos in inventory as shown in Week 0 . Use Table 11.1 to answer this question. If Big Truck Tacos makes tacos in batches of 20 , what should their MPS entry be for the first week of production? 100 80 20 60

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts