Q1) Read the article The missing ingredient? by Richard Schonberger, Industrial Engineer, June 2011, pages 2730. The article has been attached to the homework as a supplement.

- Briefly describe the assembly lines Boeing uses in its Renton manufacturing plant. What is the main objective in adopting a lean manufacturing strategy in this plant?

- Name five lean manufacturing actions taken by Boeing. For each, state what kind of waste is being eliminated or reduced.

- Under current operations, what is the main problem in the assembly line observed by the author that prevents Boeing from observing further benefits of lean manufacturing? What further changes are proposed?

- Name three advantages of the advanced lean system proposed by the author.

- What is the consolidation move that is being planned? Why does the author claim that this is not a good idea?

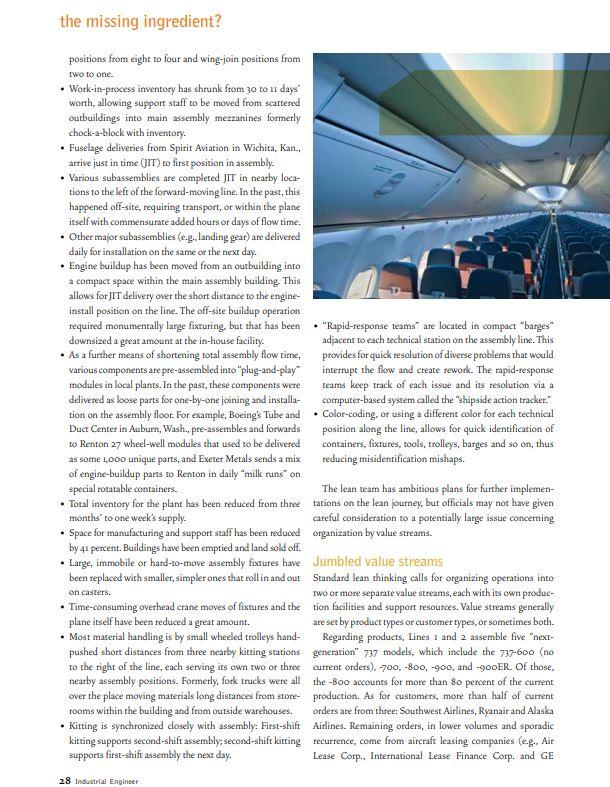

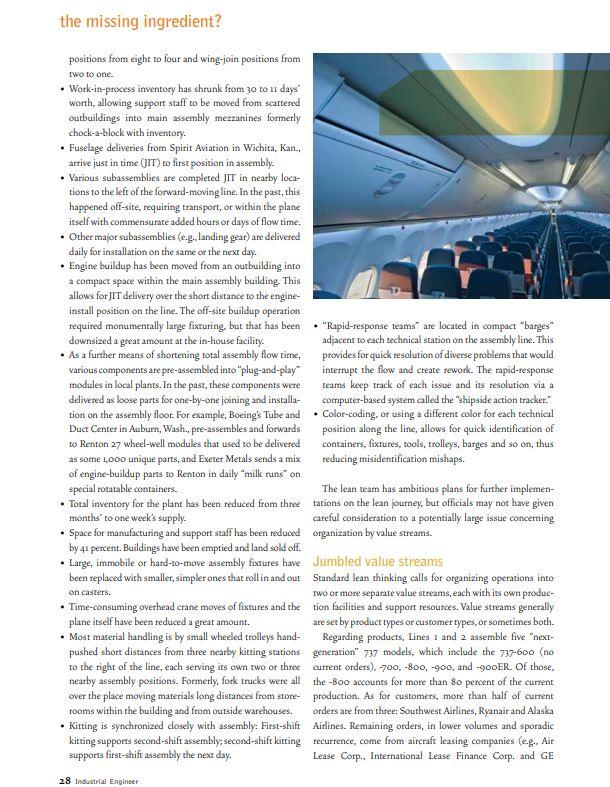

BY RICHARD ). SCHONBERGER MISSING INGREDIENT? Unjumbling value streams could make Boeing's impressive lean gains even better BOEING ASSEMBLES THE WORLD'S LARGEST-SELLING passenger aircraft, the 737, in its Renton, Wash..complex. The production rate is 31.5 aircraft per month, to be raised in stages in coming years. The Renton plant is a marvel of lean manu- facturing. A few highlights of those lean practices follow to set the stage for a discussion about a bedrock aspect of the lean agenda that is missing in Renton. Lean in Renton A well-publicized feature of 737 jer production is the moving assembly line, which became fully operational in the main assembly building in 2002. Since then, continual improve ments have been made. The moving line,call it Line 1, assembles the majority of planes. In the same building, a secondary, nonmoving line, Line 2, assembles the "overflow." A third line in a separate building is devoted to special configurations such as custom business aircraft, military versions and so forth. That the main line moves does not make the process lean, though it helps. The planes sit on transporters that move forward along a metallic pathway at a snail's pace, 2 inches per minute. That covers 80 feet, only half the distance from one position to the next. So twice per shift work pauses so the transporters can be "pulsed" forward quickly to cover the remaining distance. As assembly continues to improve with simpler, more efficient processing, the pulse time can be shortened, further reducing total flow time. That's where lean manufacturing manifests itself in collapsing the process flow time. On Line 1, that time has been reduced from 22 days to 10 days. This is a notable achievement given the complexities of managing the flow of the enormous number of unique parts - all 378,000 of them -- that go into the 737 series. Mitigating some of that complexity, the plan has the favorable planning horizon entailed by an order backlog of five and a half years. Related and contributory lean features include the following: Aircraft in process have been reduced from 27 to 11 or 10, along with consolidation of the number of assembly D June 2011 27 the missing ingredient? positions from eight to four and wing-join positions from two to one. Work-in-process inventory has shrunk from 30 to 11 days worth, allowing support staff to be moved from scattered outbuildings into main assembly mezzanines formerly chock-a-block with inventory. Fuselage deliveries from Spirit Aviation in Wichita, Kan., arrive just in time (JIT) to first position in assembly. Various subassemblies are completed JIT in nearby loca- tions to the left of the forward-moving line. In the past, this happened off-site, requiring transport, or within the plane itself with commensurate added hours or days of flow time. Other major subassemblies (e.g., landing gear) are delivered daily for installation on the same or the next day. Engine buildup has been moved from an outbuilding into a compact space within the main assembly building. This allows for JIT delivery over the short distance to the engine- install position on the line. The off-site buildup operation required monumentally large fixturing, but that has been "Rapid-response Teams" are located in compact "barges" downsized a great amount at the in-house facility. adjacent to each technical station on the assembly line. This . As a further means of shortening total assembly flow time, provides for quick resolution of diverse problems that would various components are pre-assembled into "plug-and-play interrupt the flow and create rework. The rapid-response modules in local plants. In the past, these components were teams keep track of each issue and its resolution via a delivered as loose parts for one-by-one joining and installa- computer-based system called the "shipside action tracker." tion on the assembly floor. For example, Boeing's Tube and . Color-coding, or using a different color for each technical Dua Center in Auburn, Wash., pre-assembles and forwards position along the line, allows for quick identification of to Renton 27 wheel-well modules that used to be delivered containers, fixtures, tools, trolleys, barges and so on, thus as some 1,000 unique parts, and Exeter Metals sends a mix reducing misidentification mishaps. of engine-buildup parts to Renton in daily "milk runs on special rotatable containers. The lean team has ambitious plans for further implemen- Total inventory for the plant has been reduced from three tations on the lean journey, but officials may not have given months' to one week's supply careful consideration to a potentially large issue concerning Space for manufacturing and support staff has been reduced organization by value streams. by 41 percent. Buildings have been emptied and land sold off. Large, immobile or hard-to-move assembly fixtures have Jumbled value streams been replaced with smaller, simpler ones that roll in and out Standard lean thinking calls for organizing operations into on casters. two or more separate value streams, each with its own produc- Time-consuming overhead crane moves of fixtures and the tion facilities and support resources. Value streams generally plane itself have been reduced a great amount. are set by product types or customer types, or sometimes both. . Most material handling is by small wheeled trolleys hand- Regarding products, Lines 1 and 2 assemble five "next- pushed short distances from three nearby kitting stations generation" 737 models, which include the 737-600 (no to the right of the line, each serving its own iwo or three current orders). -700,-800, -900, and -900ER. Of those, nearby assembly positions. Formerly, fork trucks were all the -8oo accounts for more than 80 percent of the current over the place moving materials long distances from store production. As for customers, more than half of current rooms within the building and from outside warehouses. orders are from three: Southwest Airlines, Ryanair and Alaska Kitting is synchronized closely with assembly: First-shift Airlines. Remaining orders, in lower volumes and sporadic kitting supports second-shift assembly; second-shift kitting recurrence, come from aircraft leasing companies (e.g., Air supports first-shift assembly the next day. Lease Corp., International Lease Finance Corp. and GE 28 Industrial Engineer The Inside of this next-generation 737-800 features the revamped Boeing Sky interior. Leasing and many different airlines. FUTURE FLIGHT From this information it would seem logi- cal for Line 1 and Line 2 to be organized into Boeing officials could decide on the future of the popu- separate value streams. Line 1 would be dedi- lar 737 jet passenger planes this year, Reuters news cated to "high runner" configurations and Line service reported. 2 to "dogs and cats" configurations, or those Randy Tinseth, the marketing vice president for ordered irregularly and in lower volumes by Boeing's commercial aircraft division, said the world's numerous other customers. second-largest plane maker expects airlines in Latin The high-runner mix of products and custom- America to demand 2,180 new planes for expansion ers for Line 1 would be based primarily on during the next 20 years. The planes would be worth commonalities: customer orders that included about $210 billion. the same sets of major, expensive-to-build aircraft subassem- Tinseth said in late April that Boeing was flight-test- blies. The mix's production load must roughly equal Line is ing improvements to the airframe and the engine. That capacity. Such a separate high-runner line would be scheduled and other improvements will have 737s delivered next as repeating mixed-model/customer modules. The schedule year about 7 percent more fuel efficient than previous would be fixed for a period of time, say, a month - with most models. But the company still was evaluating whether component deliveries and staging synchronized predictably to to build a new 737 line or add a fuel-efficient engine that month's schedule of usage on the assembly line. A first-cur to existing production plan - to be refined through analysis - might be to dedicate The Financial Times reported that a radical revamp Line I to the 737-800 series and orders from perhaps two of could include a new aircraft with a main body of plastic the largest three customers, say, Southwest and Ryan. However composites. Another option would replace the single- it tums out, this two-value-stream strategy is not inviolable. aisle 737 with a new twin-aisle aircraft. Either line maintains the flexibility to assemble any model, and situations could arise for one or more high runners to go to Let's take a closer look at the workings and likely payoff of Line 2, or dogs-cats to Line 1. the advanced lean strategy. On dedicated Line : Nothing like that strategy is operative in Renton, Rather, on both Line 1 and Line 2, aircraft models/customer orders are . In operating the dominant configuration line to a repeating sequenced irregularly, which is tantamount to treating each mixed-model schedule, that regularity passes back to suppli- plane undergoing assembly as a separate project. The consid- ers, greatly simplifying their operations and making them erable benefits of dedicated production by two separate value more routine. Significant inventory and cost reductions streams are squandered, as is the main benefit of the moving would accrue in nearly every aspect of Renton operations assembly line: regularity. and upstream to suppliers and their suppliers. Asit stands, Line 1 moves the planes like clockwork, but since . The repeating, mixed-model line offers, in addition, advan- the configurations are scrambled, so are the requirements for tageous delivery regularity to 737 customers. component modules, parts, tooling, material deliveries and Kirting becomes partially more routine, allowing for a regu- employee skills. Irregularity of parts requirements requires lar, repeating takt-time-like schedule without the need for extra buffer inventories at Renton and upstream in the supply pick lists. For frequently used kits, each is conveyed by a chains. Even though the added buffer inventories of suppli- pait of dedicated trolleys, one at the point of use and its ers are on their balance sheets, Boeing pays for that inventory twin back at the kitting site being filled. This lowers the in higher supplier prices stemming from the suppliers' higher direct costs and overhead costs of kitting, which currently inventory carrying costs. is- at least for parts not common to successive aircraft - June 2011 29 the missing ingredient? . a one-off scramble for each plane coming down the line. value streams dim both the sight lines through supply and Issues that confront the rapid-response teams in their customer echelons and linkages with company support func- barges and that enter the shipside action tracker are reduced tions, including critical costing and pricing. considerably. Under the present system, most of those The engineering mindset is strong at Boeing, since engi- concerns may be related to delays on incoming materi- neers are inherently the dominant force at the company. als, wrong or defective parts, and assembler errors related That being so, it is no surprise that some have said Renton is to excessive part-number variety and lack of repeatability. considering a move to consolidate Line 2 into Line 1. For the dedicated line, numbers of shipside action tracker That's not a good idea. Accommodating so many more issues are cut by as much as half- orders into a single assembly line would stretch out average With fewer issues, the rapid-response teams and their tech lead times, and every increment of lead time carries a realm of nical support backup shrink in size and budget. added costs with it. More planes would need to be undergoing With fewer issues and much more repeatability, flow time assembly in increased numbers of technical stations, reversing soon falls to say, eight days or less instead of 11 days, with some standout lean-based gains of the past few years. And a commensurate increased Line 1 capacity. single line raises the likelihood, frequency and risk of a single Total production costs are lowered considerably, and product serious disruption rippling negatively along the entire line. costing becomes a lot sharper since cost assignment would The idea of a single super line would have made more sense be focused narrowly on a limited number of configurations in the 737's pre-lean era. At that time the massive, costly tool- The two or three dominant customers get further price ing fixtures were resistant to being moved. Much of assembly breaks, thus solidifying their commitment to Boeing 737 depended on frequent, costly, time-consuming moves of the and helping ward off Airbus and Bombardier incursions. aircraft itself and of major aircraft modules by a massive over- . With costs and prices of the dominant configurations bead crane built into the building. So assembly needed to be lowered, one or a few configuration "packages" might be in a bay beneath an overhead crane and near the bulky fixtures. marketed as high-volume, low-priced "standard configura- Now, with smaller, simpler, mostly mobile facilities and tions" - standard, that is, with regard to many of the most material handling, assembly lines can go about any place costly subsystems, while still accommodating customer large enough to accommodate the length and wing spans preferences in, especially, passenger-service facilities. That a few planes, although the existing overhead crane is still in marketing strategy would aim at getting other airlines, use and useful. In other words, consolidating into a single line those now in the dogs-and-cats ordering mode, to switch now offers very little in the way of monetary savings in physi- to orders conforming more closely to a standard package. cal facilities savings that engineers typically count on in The main attraction: A standard configuration is costed and support of their consolidation proclivities. priced at $5 million to $15 million less than low-volume, The Renton 737's lean production design is outstanding in irregularly ordered dog-cat configurations. many respects and ranks among the lean world's best exam- Overall results indude greater sales and market share; ples. However, there seems to be a missing ingredient, one higher margins via lower overhead and direct costs plus that should beneficially combine the lean assembly design lower supplier and customer service costs; more money to with other aspects of the competitive whole invest in continual upgrading of the 737 aircraft design and orders, production/delivery lead times, predictability, simplic- production, and an extended lifecycle for the brand. ity, supplier costs and lead times, total costs, prices, profit margins and quality. A hard focus on value-stream identity for What else? dominant plane configurations and customers could be that The engineering mindset includes a preference for consoli- missing ingredient. dation: If the product line is manufactured in four modestly sized buildings, then enlarge one of them enough to accom- Richard Schonberger is president of Schonberger & Associates Inc. modate all the products under a single roof. And if the product of Seattle. He has authored more than 170 articles and papers, a line is manufactured on four separate production lines, design 12-volume video set and several books, including Best Practices in a single super line capable and flexible enough to accommo- Lean Six Sigma Process Improvement: A Deeper Look... date all the products - a prideful engineering feat. However, Telling Evidence from the Leanness Studies. Schonberger was a consolidation into a single line is a complex endeavor, costly practicing industrial engineer and then a professor at the University of to engineer, install and maintain. Moreover, its muddled Nebraska teaching production management and information systems. of customers, a 30 Industrial Engineer