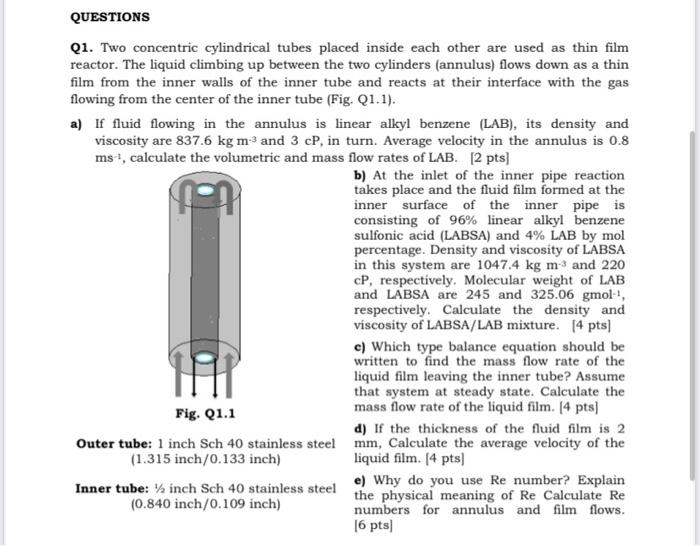

Question: Q1. Two concentric cylindrical tubes placed inside each other are used as thin film reactor. The liquid climbing up between the two cylinders (annulus) flows

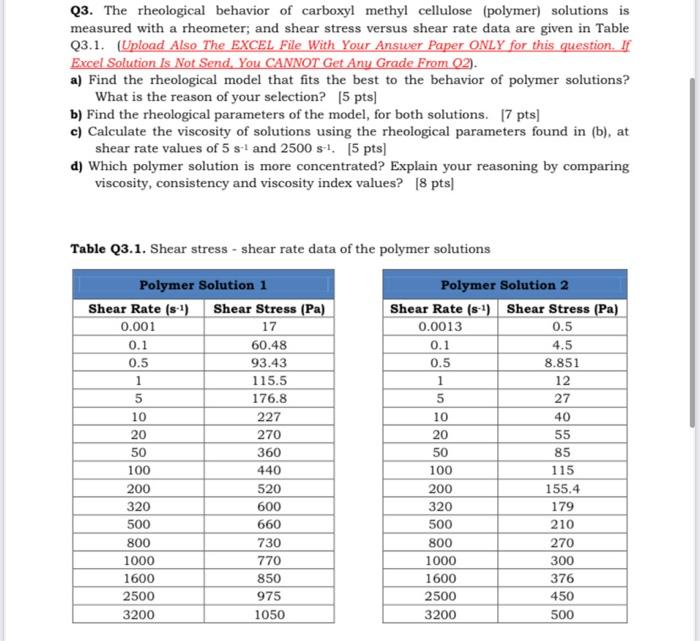

Q1. Two concentric cylindrical tubes placed inside each other are used as thin film reactor. The liquid climbing up between the two cylinders (annulus) flows down as a thin film from the inner walls of the inner tube and reacts at their interface with the gas flowing from the center of the inner tube (Fig. Q1.1). a) If fluid flowing in the annulus is linear alkyl benzene (LAB), its density and viscosity are 837.6kgm3 and 3cP, in turn. Average velocity in the annulus is 0.8 ms1, calculate the volumetric and mass flow rates of LAB. [2 pts] b) At the inlet of the inner pipe reaction takes place and the fluid film formed at the inner surface of the inner pipe is consisting of 96% linear alkyl benzene sulfonic acid (LABSA) and 4\% LAB by mol percentage. Density and viscosity of LABSA in this system are 1047.4kgm3 and 220 cP, respectively. Molecular weight of LAB and LABSA are 245 and 325.06 gmol 1, respectively. Calculate the density and viscosity of LABSA/LAB mixture. [4 pts] c) Which type balance equation should be written to find the mass flow rate of the liquid film leaving the inner tube? Assume that system at steady state. Calculate the mass flow rate of the liquid film. [4 pts] d) If the thickness of the fluid film is 2 Outer tube: 1 inch Sch 40 stainless steel mm, Calculate the average velocity of the (1.315 inch/0.133 inch) liquid film. [4 pts] Inner tube: 1/2 inch Sch 40 stainless steel e) Why do you use Re number? Explain (0.840 inch/0.109 inch) the physical meaning of Re Calculate Re numbers for annulus and film flows. [6 pts] Q3. The rheological behavior of carboxyl methyl cellulose (polymer) solutions is measured with a rheometer; and shear stress versus shear rate data are given in Table Q3.1. (Upload Also The EXCEL File With Your Answer Paper ONLY for this question. If. Excel Solution Is Not Send. You CANNOT Get Any Grade From Q2). a) Find the rheological model that fits the best to the behavior of polymer solutions? What is the reason of your selection? [5 pts] b) Find the rheological parameters of the model, for both solutions. [7 pts] c) Calculate the viscosity of solutions using the rheological parameters found in (b), at shear rate values of 5s1 and 2500s1. [5 pts] d) Which polymer solution is more concentrated? Explain your reasoning by comparing viscosity, consistency and viscosity index values? [8 pts] Table Q3.1. Shear stress - shear rate data of the polymer solutions Q1. Two concentric cylindrical tubes placed inside each other are used as thin film reactor. The liquid climbing up between the two cylinders (annulus) flows down as a thin film from the inner walls of the inner tube and reacts at their interface with the gas flowing from the center of the inner tube (Fig. Q1.1). a) If fluid flowing in the annulus is linear alkyl benzene (LAB), its density and viscosity are 837.6kgm3 and 3cP, in turn. Average velocity in the annulus is 0.8 ms1, calculate the volumetric and mass flow rates of LAB. [2 pts] b) At the inlet of the inner pipe reaction takes place and the fluid film formed at the inner surface of the inner pipe is consisting of 96% linear alkyl benzene sulfonic acid (LABSA) and 4\% LAB by mol percentage. Density and viscosity of LABSA in this system are 1047.4kgm3 and 220 cP, respectively. Molecular weight of LAB and LABSA are 245 and 325.06 gmol 1, respectively. Calculate the density and viscosity of LABSA/LAB mixture. [4 pts] c) Which type balance equation should be written to find the mass flow rate of the liquid film leaving the inner tube? Assume that system at steady state. Calculate the mass flow rate of the liquid film. [4 pts] d) If the thickness of the fluid film is 2 Outer tube: 1 inch Sch 40 stainless steel mm, Calculate the average velocity of the (1.315 inch/0.133 inch) liquid film. [4 pts] Inner tube: 1/2 inch Sch 40 stainless steel e) Why do you use Re number? Explain (0.840 inch/0.109 inch) the physical meaning of Re Calculate Re numbers for annulus and film flows. [6 pts] Q3. The rheological behavior of carboxyl methyl cellulose (polymer) solutions is measured with a rheometer; and shear stress versus shear rate data are given in Table Q3.1. (Upload Also The EXCEL File With Your Answer Paper ONLY for this question. If. Excel Solution Is Not Send. You CANNOT Get Any Grade From Q2). a) Find the rheological model that fits the best to the behavior of polymer solutions? What is the reason of your selection? [5 pts] b) Find the rheological parameters of the model, for both solutions. [7 pts] c) Calculate the viscosity of solutions using the rheological parameters found in (b), at shear rate values of 5s1 and 2500s1. [5 pts] d) Which polymer solution is more concentrated? Explain your reasoning by comparing viscosity, consistency and viscosity index values? [8 pts] Table Q3.1. Shear stress - shear rate data of the polymer solutions

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts