Question: Q2. A polystyrene component must not fail when a tensile stress of 3.0MPa is applied. Determine the maximum allowable surface crack length if the surface

Q2. A polystyrene component must not fail when a tensile stress of

3.0MPais applied. Determine\ the maximum allowable surface crack length if the surface energy of polystyrene is

0.50(J)/(m^(2)).\ Assume a modulus of elasticity of

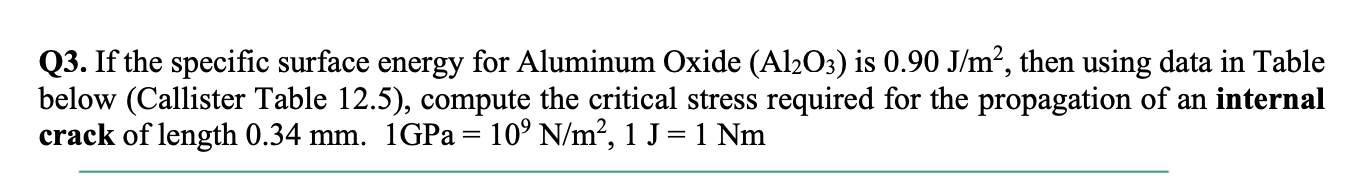

2.5GPa.1GPa=10^(9)(N)/(m^(2)),1J=1NmQ3. If the specific surface energy for Aluminum Oxide

(Al_(2)O_(3))is

0.90(J)/(m^(2)), then using data in Table\ below (Callister Table 12.5), compute the critical stress required for the propagation of an internal\ crack of length

0.34mm.1GPa=10^(9)(N)/(m^(2)),1J=1Nm

Q3. If the specific surface energy for Aluminum Oxide (Al2O3) is 0.90J/m2, then using data in Table below (Callister Table 12.5), compute the critical stress required for the propagation of an internal crack of length 0.34mm.1GPa=109N/m2,1J=1Nm Q3. If the specific surface energy for Aluminum Oxide (Al2O3) is 0.90J/m2, then using data in Table below (Callister Table 12.5), compute the critical stress required for the propagation of an internal crack of length 0.34mm.1GPa=109N/m2,1J=1Nm

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts