Question: QUALITY CONTROLCASE STUDY ASSIGNMENT SEMESTER II SESSION 2020/2021 Cecil Rice Export operates a facility in Tg. Karang, Selangor, where bulk white rice is bagged for

QUALITY CONTROLCASE STUDY ASSIGNMENT

SEMESTER II SESSION 2020/2021

Cecil Rice Export operates a facility in Tg. Karang, Selangor, where bulk white rice is bagged for export in 70kg grain bags. The bagged rice is then palletized and brought by truck to a quay in the harbor and loaded onto a break-bulk ship for transport to foreign customers.

Cecil Rice Export has experienced good growth in the past decade due to a concentration on continuos improvement and lean techniques. It has gained an enviable reputation for being a low-cost, high-value supplier. This growth has led to the need to increase capacity by expanding the number of shifts at Cecil Rice Exports facility. In 2005, it operated only one shift, from 08:00 to 16:00. In 2007, a second shift was added and the facility operated from 04:00 to 20:00, switching shifts at 12:00. Since the start of 2009, the company has increased to three shifts, operating from 00:00 to 08:00, 08:00 to 16:00 and 16:00 to 00:00. As these shifts were added, most of the more experienced employees, due to seniority, chose to remain on the day shift. Those originally on the second shift added in 2007 (at that time the 12:00 to 20:00 shift) mostly moved onto the 16:00 to 00:00 shift. Those on the shift added in 2009, the greenest shift, were therefore left with the 00:00 to 08:00 shift. As the new shift was added, some senior personnel were assigned to the new shifts to break in the new workforce. Eventually, these experienced hands returned to their preferred day shift. Traditionally, working bonds between shift members have resulted in a good amount of cohesion in the workforce and shift members are usually quite averse to changing shifts.

Rice is delivered to the Cecil Rice Export facility and stored in a silo. From the silo, an air-powered transport system moves the grain to the hopper of the bagging machine. The bagging machine fills bags from the hopper to a specific weight, 70kg and past records indicate that the mean is in fact 70.0kg with a standard deviation of 1.0kg. This machine, however, is very sensitive and requires calibration by trained personnel. In the past, this was not a problem due to the experience of the personnel in the original production shift. As shifts were added, there was no effort to examine whether the weight of the bags remained within acceptable limits.

Recently, during the loading of the pallets on the merchant ship, the ships officers have detected abnormalities in the pallets. The pallets are loaded with 30 bags each, for a presumed weight of 2,100kg. When confronted with abnormalities, plant management initially suspected the bagging operation and specifically over or underweight bags. Both under and overweight bags are undesirable from the firms point of view. Overweight bags decrease Cecil Rice Exports revenue as product is given away in the overage. Underweight bags, on the other hand, are a customer service issue. Cecil Rice Exports customers have come to expect bags to have a proper weight and are dissapointed when the bags are underweight.

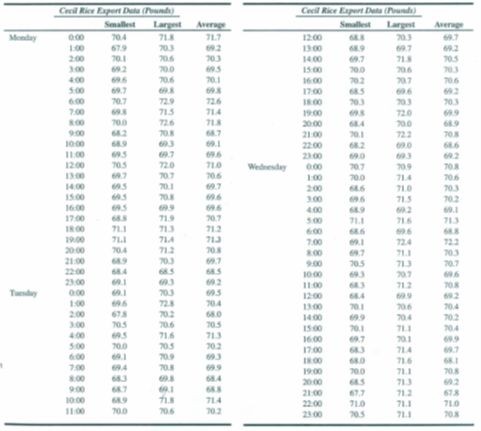

For these reasons, over and underweight bags are equally undesirable. The following table (as shown in next page) shows the minimum, maximum and average from hourly samples of five bags per hour, taken over three days.

TASK

Work and carry out the following tasks:

- Applying SPC tools and techniques in solving the problem.

- The control chart must be developed base on days and shifts to see the differences.

- Produce a group report with the following details:

- Introduction

- Problem statement and objectives

- Problems/ data analysis( Use minitab software if possible )

- Discussion and Proposed solutions

- Reflection & Conclusion

Report Specification

Assessment Marks : 20% from the total assessment marks, 60%

Average 71.7 Cecil Rior Expert Dele (Pund) Smallest 12.00 Monday 69.7 71 703 605 7025 702 14.00 15.00 16:00 17:00 18.00 19:00 707 696 706 70 703 714 687 701 Cecil Rice Export Data (Pan) Smallest Largest 718 679 2.00 701 706 700 706 5.00 69.7 70.7 720 715 700 9.00 10:00 11.00 695 6.7 12.00 705 707 14.00 701 15.00 16.00 60 17.00 63 719 711 19.00 71.1 71.4 71.2 21:00 689 703 64 GRS 720 700 722 690 21:00 22.00 23:00 696 710 706 69.7 Wednesday 707 70.0 1:00 200 3.00 209 714 710 715 602 716 686 602 703 706 703 702 691 707 712 713 686 724 710 713 703 707 7035 685 10:00 11:00 12.00 712 703 Tuesday 0:00 695 704 728 702 701 70,6 70.4 70 704 705 711 691 696 678 7035 695 70,0 691 694 683 701 69.7 716 205 709 703 702 693 15.00 16:00 17.00 18.00 19.00 6.00 7.00 60 700 681 703 714 716 711 713 712 711 711 9:00 10.00 684 68 714 69.1 21:00 22.00 23:00 677 710 705 700 706 710 708Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts