Question: Quality Improvement Techniques CASE STUDY 1 Process Improvement PART A. Figure 1 provides the details of a simplified version of a bracket used to hold

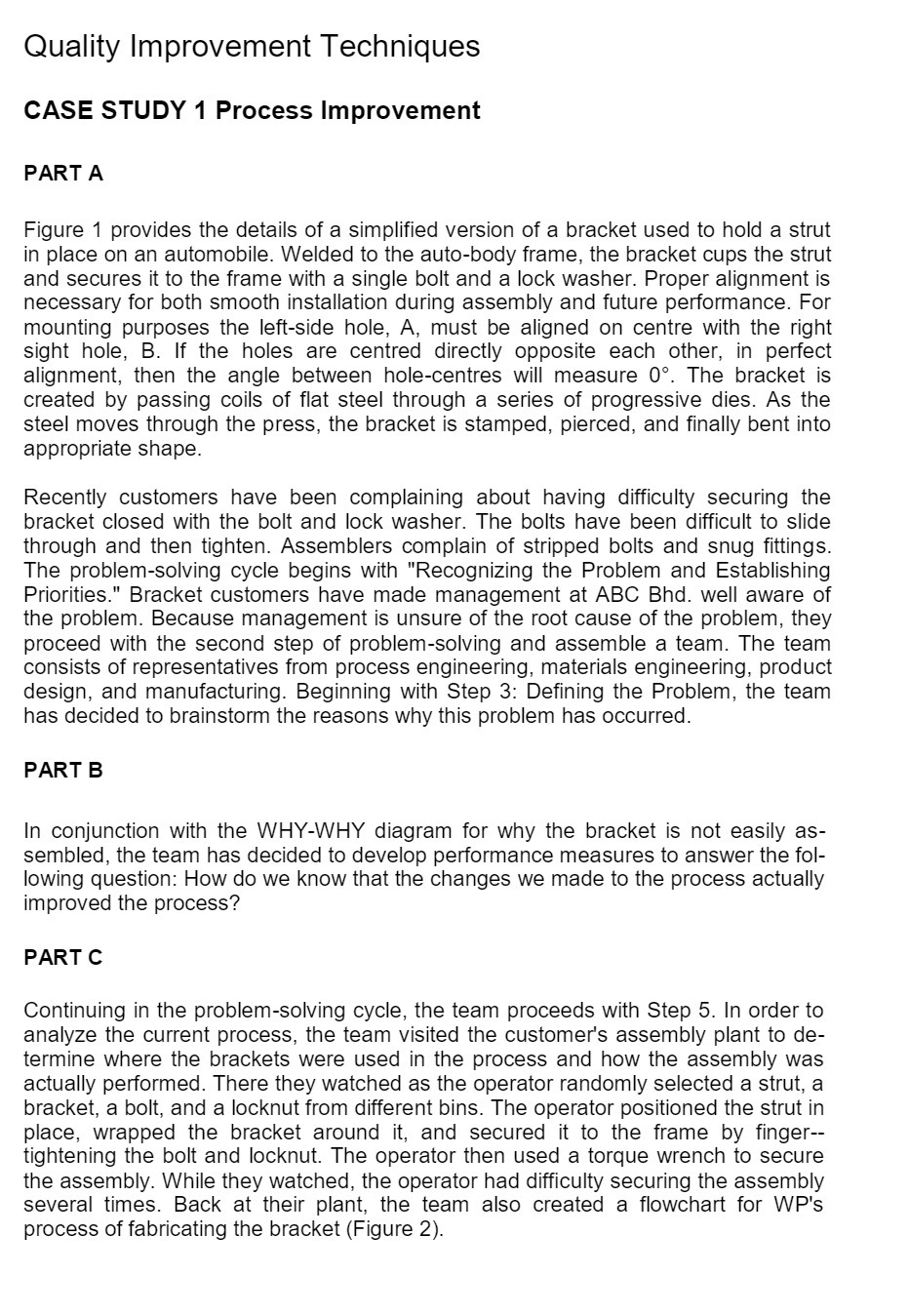

Quality Improvement Techniques CASE STUDY 1 Process Improvement PART A. Figure 1 provides the details of a simplified version of a bracket used to hold a strut in place on an automobile. Welded to the auto-body frame, the bracket cups the strut and secures it to the frame with a single bolt and a lock washer. Proper alignment is necessary for both smooth installation during assembly and future performance. For mounting purposes the left-side hole, A, must be aligned on centre with the right sight hole, B. If the holes are centred directly opposite each other, in perfect alignment, then the angle between hole-centres will measure 0. The bracket is created by passing coils of at steel through a series of progressive dies. As the steel moves through the press, the bracket is stamped, pierced, and nally bent into appropriate shape. Recently customers have been complaining about having difficulty securing the bracket closed with the bolt and lock washer. The bolts have been difficult to slide through and then tighten. Assemblers complain of stripped bolts and snug ttings. The problem-solving cycle begins with "Recognizing the Problem and Establishing Priorities." Bracket customers have made management at ABC Bhd. well aware of the problem. Because management is unsure of the root cause of the problem, they proceed with the second step of problem-solving and assemble a team. The team consists of representatives from process engineering, materials engineering, product design, and manufacturing. Beginning with Step 3: Dening the Problem, the team has decided to brainstorm the reasons why this problem has occurred. PART B In conjunction with the WHY-WHY diagram for why the bracket is not easily as- sembled, the team has decided to develop performance measures to answer the fol- lowing question: How do we know that the changes we made to the process actually improved the process? PART C Continuing in the problem-solving cycle, the team proceeds with Step 5. In order to analyze the current process, the team visited the customer's assembly plant to de- termine where the brackets were used in the process and now the assembly was actually performed. There they watched as the operator randomly selected a strut, a bracket, a bolt, and a locknut from different bins. The operator positioned the strut in place, wrapped the bracket around it, and secured it to the frame by finger- tightening the bolt and locknut. The operator then used a torque wrench to secure the assembly. While they watched, the operator had difficulty securing the assembly several times. Back at their plant, the team also created a owchart for WP's process of fabricating the bracket (Figure 2)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts