Question: Quality Management Plan It is important in any project that quality be measured at every stage of design, development, and throughout the entire manufacturing sector.

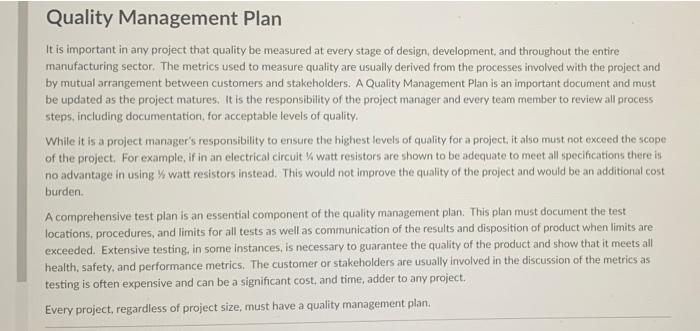

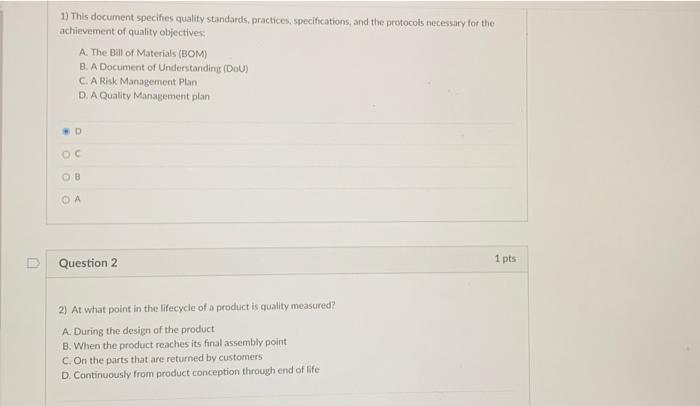

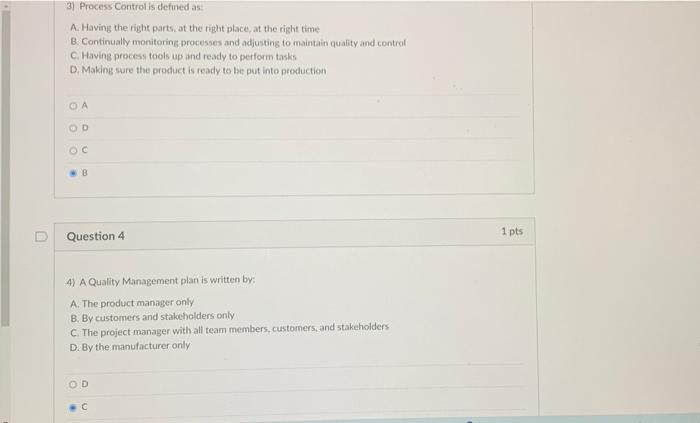

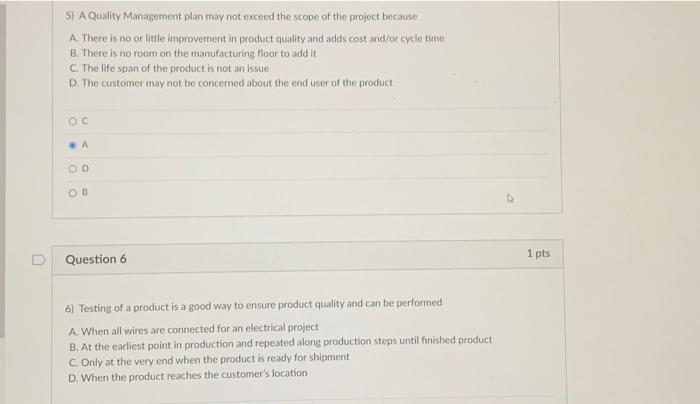

Quality Management Plan It is important in any project that quality be measured at every stage of design, development, and throughout the entire manufacturing sector. The metrics used to measure quality are usually derived from the processes involved with the project and by mutual arrangement between customers and stakeholders. A Quality Management Plan is an important document and must be updated as the project matures. It is the responsibility of the project manager and every team member to review all process steps, including documentation, for acceptable levels of quality. While it is a project manager's responsibility to ensure the highest levels of quality for a project, it also must not exceed the scope of the project. For example, if in an electrical circuit watt resistors are shown to be adequate to meet all specifications there is no advantage in using % watt resistors instead. This would not improve the quality of the project and would be an additional cost burden A comprehensive test plan is an essential component of the quality management plan. This plan must document the test locations, procedures, and limits for all tests as well as communication of the results and disposition of product when limits are exceeded. Extensive testing, in some instances, is necessary to guarantee the quality of the product and show that it meets all health, safety and performance metrics. The customer or stakeholders are usually involved in the discussion of the metrics as testing is often expensive and can be a significant cost, and time, adder to any project. Every project, regardless of project size, must have a quality management plan. 1) This document specifies quality standards, practices, specifications, and the protocols necessary for the achievement of quality objectives A. The Bill of Materials (BOM) B. A Document of Understanding (DU) C. A Risk Management Plan D. A Quality Management plan D OB 0 A Question 2 1 pts 2) At what point in the lifecycle of a product is quality measured? A. During the design of the product B. When the product reaches its final assembly point C. On the parts that are returned by customers D. Continuously from product conception through end of life 3) Process Control is defined as A. Having the right parts at the right place, at the right time B. Continually monitoring processes and adjusting to maintain quality and control C. Having process tools up and ready to perform tasks D. Malding sure the product is ready to be put into production OD U Question 4 1 pts 4) A Quality Management plan is written by: A. The product manager only B. By customers and stakeholders only C. The project manager with all team members, customers, and stakeholders D. By the manufacturer only @D 5) A Quality Management plan may not exceed the scope of the project because A. There is no or little improvement in product quality and adds cost and/or cycle time B. There is no room on the manufacturing floor to add it C. The life span of the product is not an issue D. The customer may not be concerned about the end user of the product A OD 1 pts Question 6 6) Testing of a product is a good way to ensure product quality and can be performed A When all wires are connected for an electrical project B. At the earliest point in production and repeated along production steps until finished product C. Only at the very end when the product is ready for shipment D. When the product reaches the customer's location

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts