Question: Que 1 : Quality Control in Aircraft Component Manufacturing ( See Notes 5 ) In an aerospace manufacturing plant, two processes, Process X and Process

Que : Quality Control in Aircraft Component Manufacturing See Notes

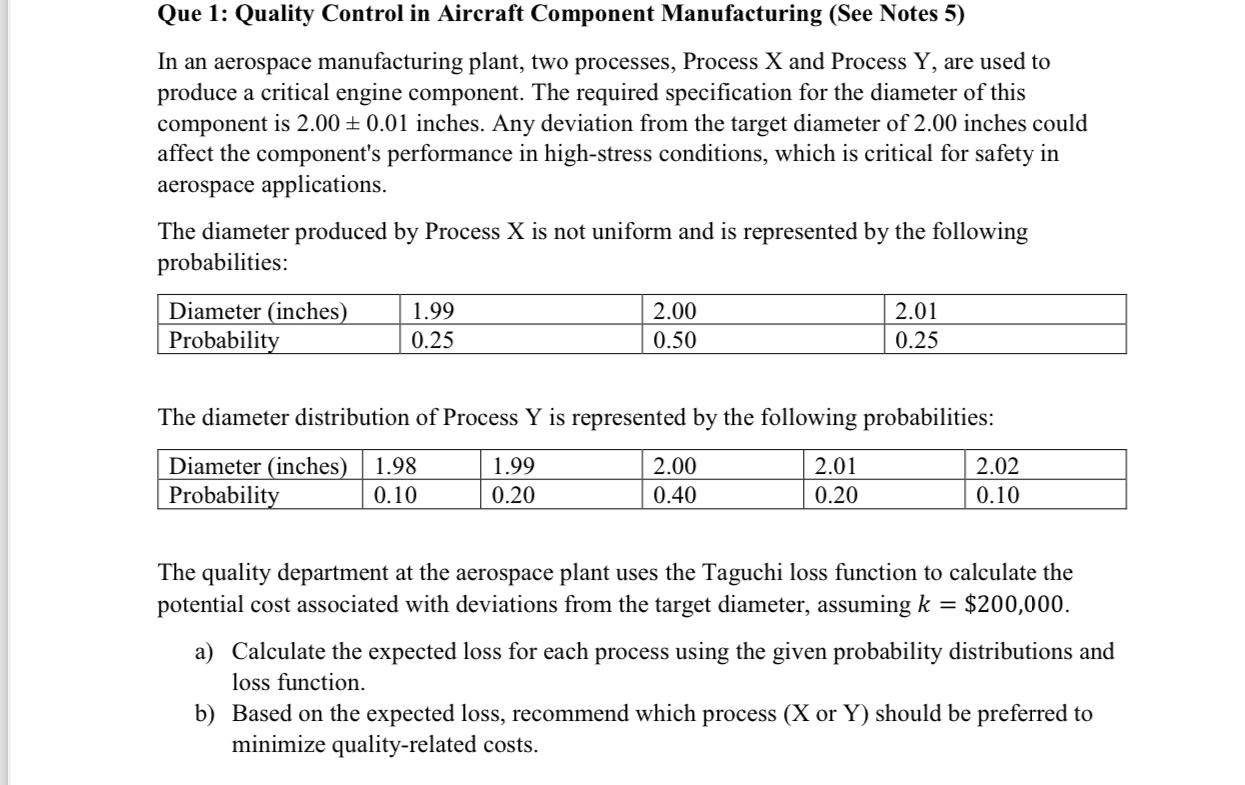

In an aerospace manufacturing plant, two processes, Process X and Process Y are used to produce a critical engine component. The required specification for the diameter of this component is inches. Any deviation from the target diameter of inches could affect the component's performance in highstress conditions, which is critical for safety in aerospace applications.

The diameter produced by Process X is not uniform and is represented by the following probabilities:

tableDiameter inchesProbability

The diameter distribution of Process Y is represented by the following probabilities:

tableDiameter inchesProbability

The quality department at the aerospace plant uses the Taguchi loss function to calculate the potential cost associated with deviations from the target diameter, assuming $

a Calculate the expected loss for each process using the given probability distributions and loss function.

b Based on the expected loss, recommend which process X or Y should be preferred to minimize qualityrelated costs.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock