Question: Question 1 & 2 already complete. begin{tabular}{|l|c|c|} hline & Standard Tiller & Custom Tiller hline Annual Sales & 3,000 units & 4,000 units

Question 1 & 2 already complete.

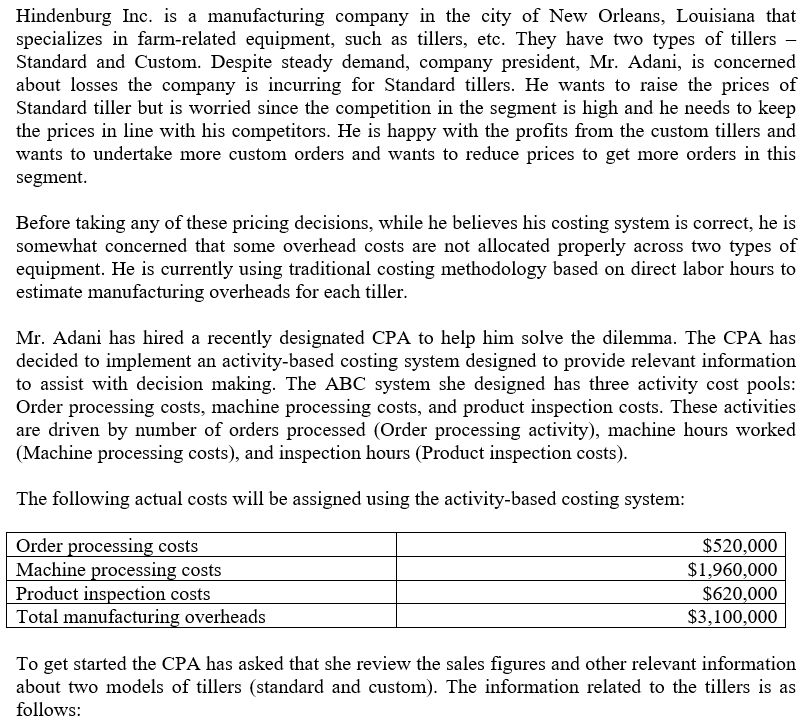

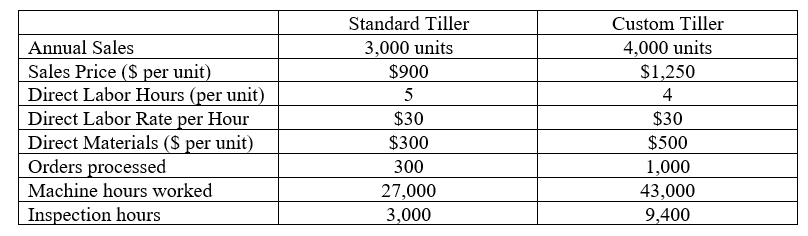

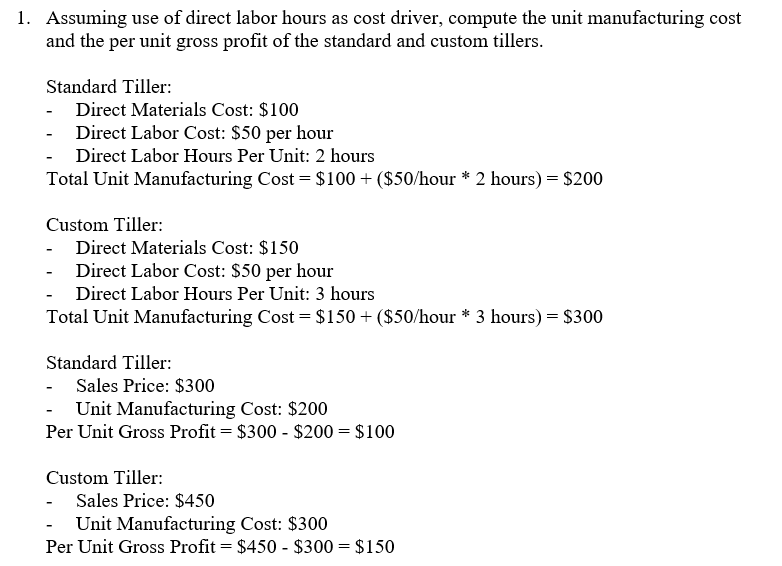

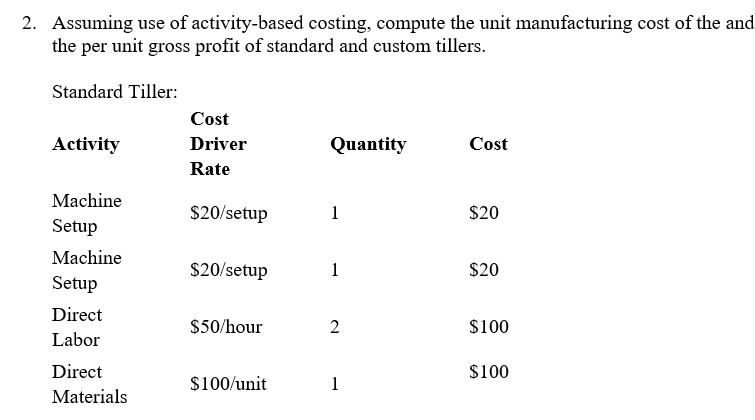

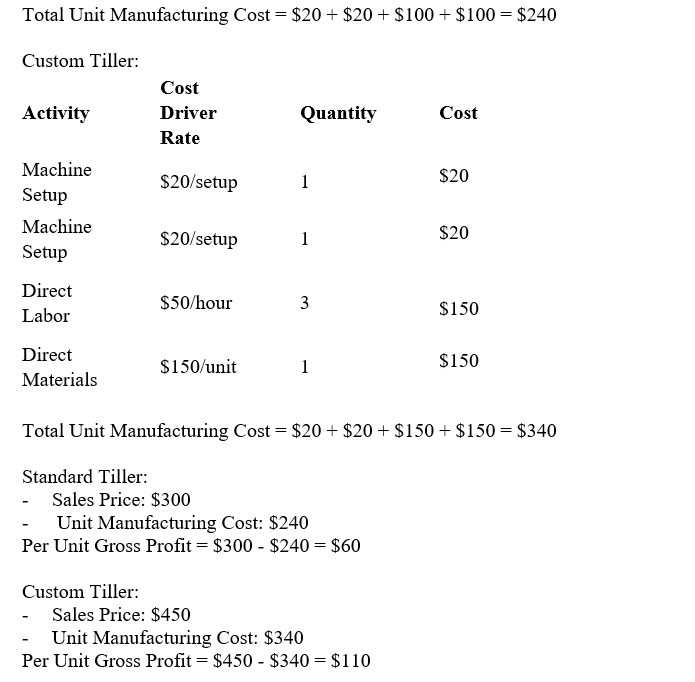

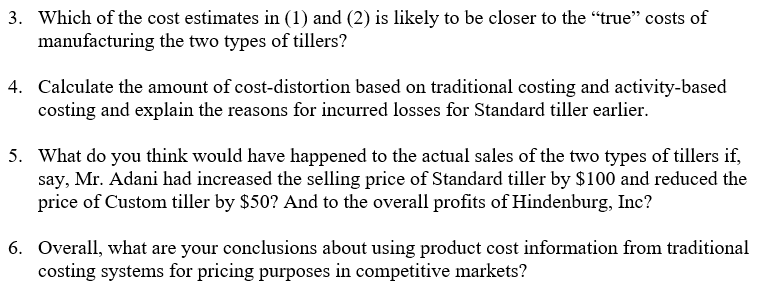

\begin{tabular}{|l|c|c|} \hline & Standard Tiller & Custom Tiller \\ \hline Annual Sales & 3,000 units & 4,000 units \\ \hline Sales Price (\$ per unit) & $900 & $1,250 \\ \hline Direct Labor Hours (per unit) & 5 & 4 \\ \hline Direct Labor Rate per Hour & $30 & $30 \\ \hline Direct Materials (\$ per unit) & $300 & $500 \\ \hline Orders processed & 300 & 1,000 \\ \hline Machine hours worked & 27,000 & 43,000 \\ \hline Inspection hours & 3,000 & 9,400 \\ \hline \end{tabular} Total Unit Manufacturing Cost =$20+$20+$100+$100=$240 Custom Tiller: Total Unit Manufacturing Cost =$20+$20+$150+$150=$340 Standard Tiller: - Sales Price: $300 - Unit Manufacturing Cost: $240 Per Unit Gross Profit =$300$240=$60 Custom Tiller: - Sales Price: $450 - Unit Manufacturing Cost: $340 Per Unit Gross Profit =$450$340=$110 3. Which of the cost estimates in (1) and (2) is likely to be closer to the "true" costs of manufacturing the two types of tillers? 4. Calculate the amount of cost-distortion based on traditional costing and activity-based costing and explain the reasons for incurred losses for Standard tiller earlier. 5. What do you think would have happened to the actual sales of the two types of tillers if, say, Mr. Adani had increased the selling price of Standard tiller by $100 and reduced the price of Custom tiller by $50 ? And to the overall profits of Hindenburg, Inc? 6. Overall, what are your conclusions about using product cost information from traditional costing systems for pricing purposes in competitive markets? 2. Assuming use of activity-based costing, compute the unit manufacturing cost of the and the per unit gross profit of standard and custom tillers. Standard Tiller: Hindenburg Inc. is a manufacturing company in the city of New Orleans, Louisiana that specializes in farm-related equipment, such as tillers, etc. They have two types of tillers Standard and Custom. Despite steady demand, company president, Mr. Adani, is concerned about losses the company is incurring for Standard tillers. He wants to raise the prices of Standard tiller but is worried since the competition in the segment is high and he needs to keep the prices in line with his competitors. He is happy with the profits from the custom tillers and wants to undertake more custom orders and wants to reduce prices to get more orders in this segment. Before taking any of these pricing decisions, while he believes his costing system is correct, he is somewhat concerned that some overhead costs are not allocated properly across two types of equipment. He is currently using traditional costing methodology based on direct labor hours to estimate manufacturing overheads for each tiller. Mr. Adani has hired a recently designated CPA to help him solve the dilemma. The CPA has decided to implement an activity-based costing system designed to provide relevant information to assist with decision making. The ABC system she designed has three activity cost pools: Order processing costs, machine processing costs, and product inspection costs. These activities are driven by number of orders processed (Order processing activity), machine hours worked (Machine processing costs), and inspection hours (Product inspection costs). The following actual costs will be assigned using the activity-based costing system: To get started the CPA has asked that she review the sales figures and other relevant information about two models of tillers (standard and custom). The information related to the tillers is as follows: Assuming use of direct labor hours as cost driver, compute the unit manufacturing co and the per unit gross profit of the standard and custom tillers. Standard Tiller: - Direct Materials Cost: $100 - Direct Labor Cost: $50 per hour - Direct Labor Hours Per Unit: 2 hours Total Unit Manufacturing Cost =$100+($50/ hour 2 hours )=$200 Custom Tiller: - Direct Materials Cost: $150 - Direct Labor Cost: $50 per hour - Direct Labor Hours Per Unit: 3 hours Total Unit Manufacturing Cost =$150+($50/ hour 3 hours )=$300 Standard Tiller: - Sales Price: $300 - Unit Manufacturing Cost: $200 Per Unit Gross Profit =$300$200=$100 Custom Tiller: - Sales Price: $450 - Unit Manufacturing Cost: $300 Per Unit Gross Profit =$450$300=$150

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts