Question: Question 1 Achieving optimal cutting speed involves two objectives, one of which is the maximization of the production rate. For maximum production rate, the speed

Question

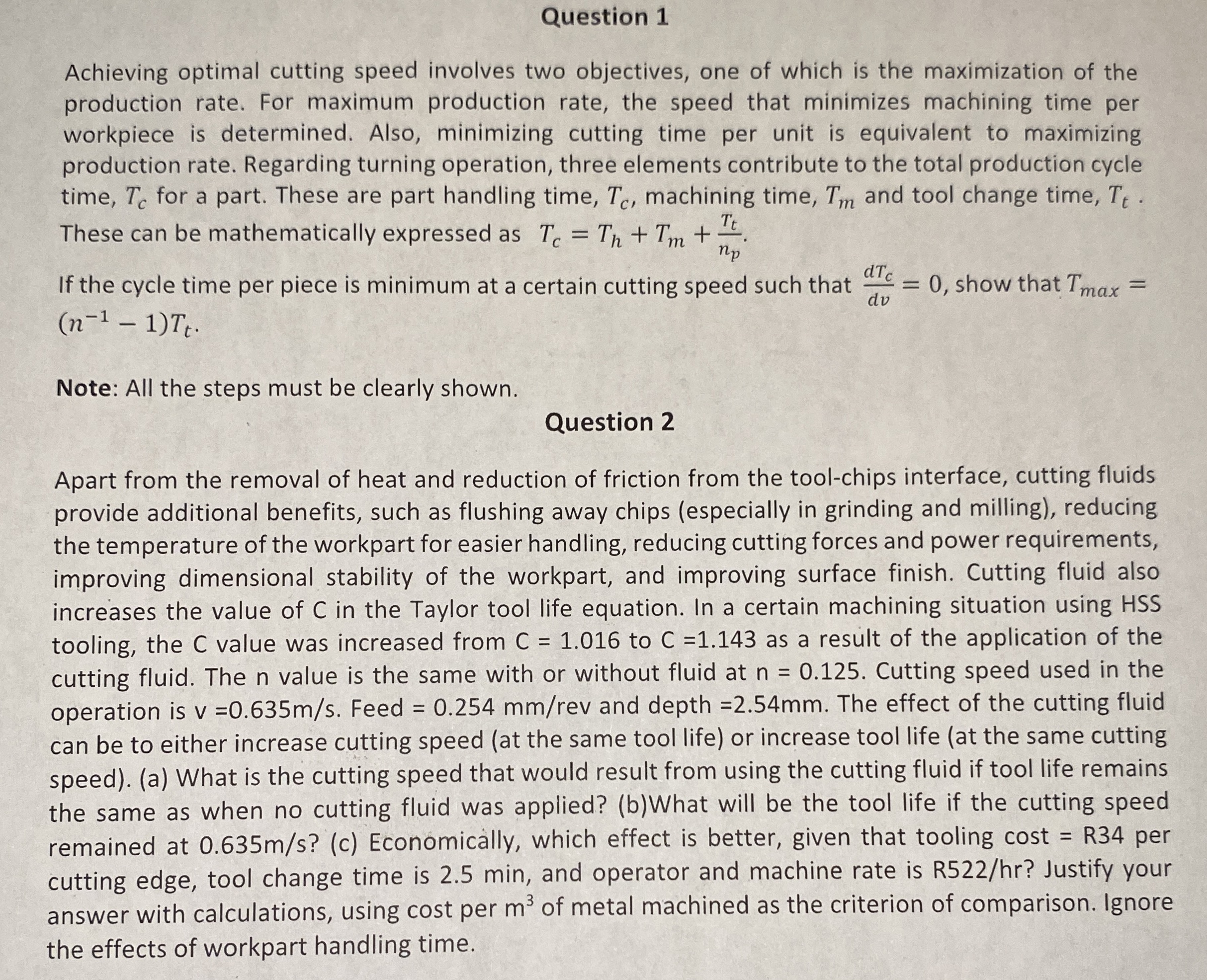

Achieving optimal cutting speed involves two objectives, one of which is the maximization of the production rate. For maximum production rate, the speed that minimizes machining time per workpiece is determined. Also, minimizing cutting time per unit is equivalent to maximizing production rate. Regarding turning operation, three elements contribute to the total production cycle time, for a part. These are part handling time, machining time, and tool change time, These can be mathematically expressed as

If the cycle time per piece is minimum at a certain cutting speed such that show that

Note: All the steps must be clearly shown.

Question

Apart from the removal of heat and reduction of friction from the toolchips interface, cutting fluids provide additional benefits, such as flushing away chips especially in grinding and milling reducing the temperature of the workpart for easier handling, reducing cutting forces and power requirements, improving dimensional stability of the workpart, and improving surface finish. Cutting fluid also increases the value of in the Taylor tool life equation. In a certain machining situation using HSS tooling, the value was increased from to as a result of the application of the cutting fluid. The value is the same with or without fluid at Cutting speed used in the operation is Feed and depth The effect of the cutting fluid can be to either increase cutting speed at the same tool life or increase tool life at the same cutting speeda What is the cutting speed that would result from using the cutting fluid if tool life remains the same as when no cutting fluid was applied? bWhat will be the tool life if the cutting speed remained at c Economically, which effect is better, given that tooling cost R per cutting edge, tool change time is min and operator and machine rate is Rhr Justify your answer with calculations, using cost per of metal machined as the criterion of comparison. Ignore the effects of workpart handling time.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock