Question: Question 1: Case study - Landmark Auto Parts, Inc. Landmark Auto Parts was founded in Egypt in 1987 as a manufacturer and supplier of various

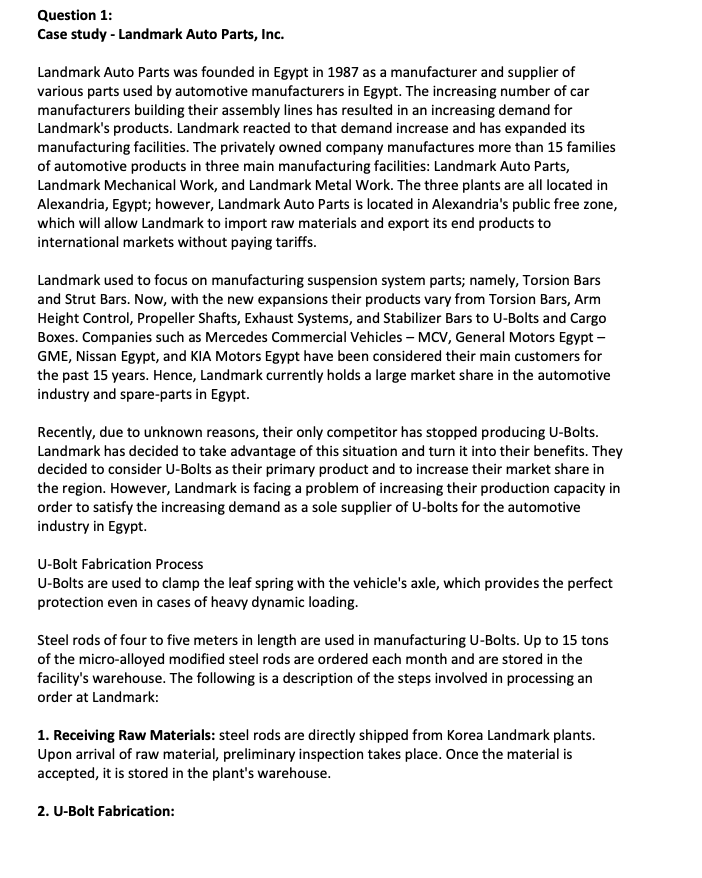

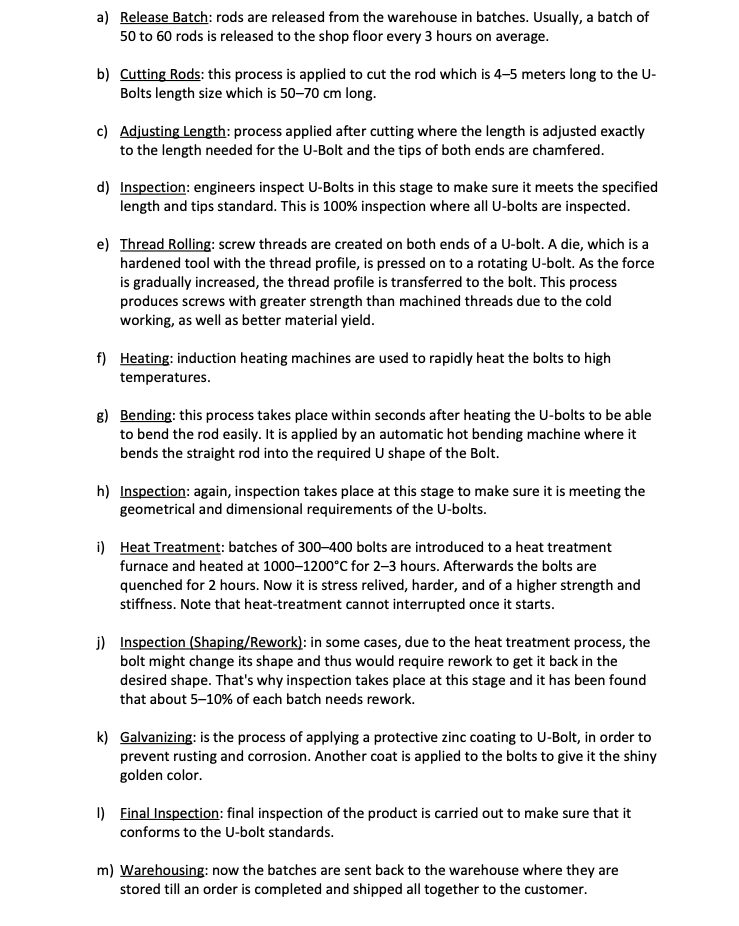

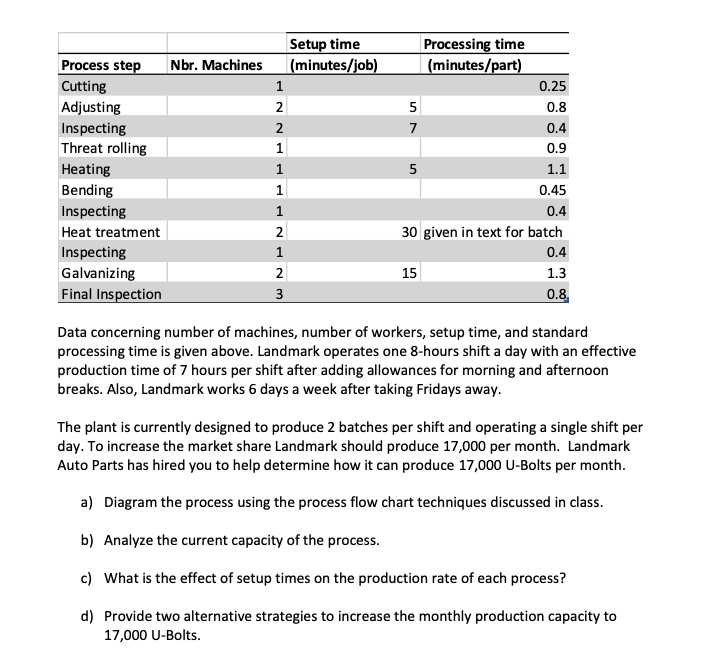

Question 1: Case study - Landmark Auto Parts, Inc. Landmark Auto Parts was founded in Egypt in 1987 as a manufacturer and supplier of various parts used by automotive manufacturers in Egypt. The increasing number of car manufacturers building their assembly lines has resulted in an increasing demand for Landmark's products. Landmark reacted to that demand increase and has expanded its manufacturing facilities. The privately owned company manufactures more than 15 families of automotive products in three main manufacturing facilities: Landmark Auto Parts, Landmark Mechanical Work, and Landmark Metal Work. The three plants are all located in Alexandria, Egypt; however, Landmark Auto Parts is located in Alexandria's public free zone, which will allow Landmark to import raw materials and export its end products to international markets without paying tariffs. Landmark used to focus on manufacturing suspension system parts; namely, Torsion Bars and Strut Bars. Now, with the new expansions their products vary from Torsion Bars, Arm Height Control, Propeller Shafts, Exhaust Systems, and Stabilizer Bars to U-Bolts and Cargo Boxes. Companies such as Mercedes Commercial Vehicles - MCV, General Motors Egypt - GME, Nissan Egypt, and KIA Motors Egypt have been considered their main customers for the past 15 years. Hence, Landmark currently holds a large market share in the automotive industry and spare parts in Egypt. Recently, due to unknown reasons, their only competitor has stopped producing U-Bolts. Landmark has decided to take advantage of this situation and turn it into their benefits. They decided to consider U-Bolts as their primary product and to increase their market share in the region. However, Landmark is facing a problem of increasing their production capacity in order to satisfy the increasing demand as a sole supplier of U-bolts for the automotive industry in Egypt. U-Bolt Fabrication Process U-Bolts are used to clamp the leaf spring with the vehicle's axle, which provides the perfect protection even in cases of heavy dynamic loading. Steel rods of four to five meters in length are used in manufacturing U-Bolts. Up to 15 tons of the micro-alloyed modified steel rods are ordered each month and are stored in the facility's warehouse. The following is a description of the steps involved in processing an order at Landmark: 1. Receiving Raw Materials: steel rods are directly shipped from Korea Landmark plants. Upon arrival of raw material, preliminary inspection takes place. Once the material is accepted, it is stored in the plant's warehouse. 2. U-Bolt Fabrication: a) Release Batch: rods are released from the warehouse in batches. Usually, a batch of 50 to 60 rods is released to the shop floor every 3 hours on average. b) Cutting Rods: this process is applied to cut the rod which is 4-5 meters long to the U- Bolts length size which is 5070 cm long. c) Adjusting Length: process applied after cutting where the length is adjusted exactly to the length needed for the U-Bolt and the tips of both ends are chamfered. d) Inspection: engineers inspect U-Bolts in this stage to make sure it meets the specified length and tips standard. This is 100% inspection where all U-bolts are inspected. e) Thread Rolling: screw threads are created on both ends of a U-bolt. A die, which is a hardened tool with the thread profile, is pressed on to a rotating U-bolt. As the force is gradually increased, the thread profile is transferred to the bolt. This process produces screws with greater strength than machined threads due to the cold working, as well as better material yield. f) Heating: induction heating machines are used to rapidly heat the bolts to high temperatures. g) Bending: this process takes place within seconds after heating the U-bolts to be able to bend the rod easily. It is applied by an automatic hot bending machine where it bends the straight rod into the required U shape of the Bolt. h) Inspection: again, inspection takes place at this stage to make sure it is meeting the geometrical and dimensional requirements of the U-bolts. i) Heat Treatment: batches of 300-400 bolts are introduced to a heat treatment furnace and heated at 1000-1200C for 2-3 hours. Afterwards the bolts are quenched for 2 hours. Now it is stress relived, harder, and of a higher strength and stiffness. Note that heat-treatment cannot interrupted once it starts. j) Inspection (Shaping/Rework): in some cases, due to the heat treatment process, the bolt might change its shape and thus would require rework to get it back in the desired shape. That's why inspection takes place at this stage and it has been found that about 5-10% of each batch needs rework. k) Galvanizing: is the process of applying a protective zinc coating to U-Bolt, in order to prevent rusting and corrosion. Another coat is applied to the bolts to give it the shiny golden color. 1) Final Inspection: final inspection of the product is carried out to make sure that it conforms to the U-bolt standards. m) Warehousing: now the batches are sent back to the warehouse where they are stored till an order is completed and shipped all together to the customer. Nbr. Machines Process step Cutting Adjusting Inspecting Threat rolling Heating Bending Inspecting Heat treatment Inspecting Galvanizing Final Inspection Setup time (minutes/job) 1 2 2 1 1 1 1 2 1 2 3 Processing time (minutes/part) 0.25 5 0.8 7 0.4 0.9 5 1.1 0.45 0.4 30 given in text for batch 0.4 15 1.3 0.8. Data concerning number of machines, number of workers, setup time, and standard processing time is given above. Landmark operates one 8-hours shift a day with an effective production time of 7 hours per shift after adding allowances for morning and afternoon breaks. Also, Landmark works 6 days a week after taking Fridays away. The plant is currently designed to produce 2 batches per shift and operating a single shift per day. To increase the market share Landmark should produce 17,000 per month. Landmark Auto Parts has hired you to help determine how it can produce 17,000 U-Bolts per month. a) Diagram the process using the process flow chart techniques discussed in class. b) Analyze the current capacity of the process. c) What is the effect of setup times on the production rate of each process? d) Provide two alternative strategies to increase the monthly production capacity to 17,000 U-Bolts