Question: Question 1, Complete the gauge capability worksheet for the dataset provided on Moodle webpage. Gauge capability analysis is of a Camshaft. CTQ dimension is .725

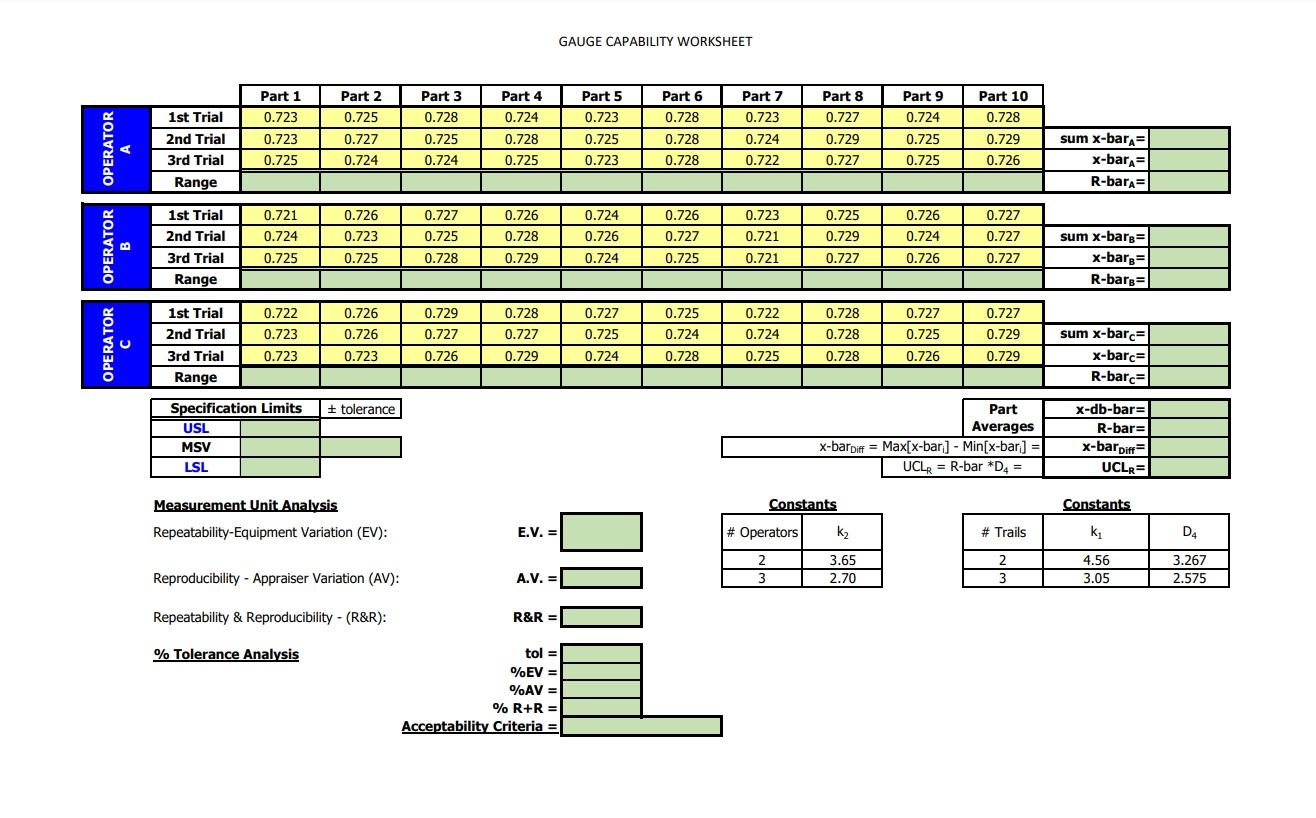

Question 1, Complete the gauge capability worksheet for the dataset provided on Moodle webpage. Gauge capability analysis is of a Camshaft. CTQ dimension is .725 +/- .005. a) Complete the excel worksheet (fill in all green highlighted fields). Create a pdf of the final excel gauge capability worksheet. b) Complete sample calculations for ALL intermediate and final calculations: a. Create a R-chart. Check for out of control points. Remove data if out of control. Create pdf of R-chart. b. Complete sample calculations as shown in class. State your assessment of this gauge. c) Provided the true reading on piece 2 is 0.727: a. Calculate the average measurement. b. Calculate the accuracy shift. c. State the 99% range in gauge readings. d. State the 99% range in true readings. e. Calculate the maximum possible deflection. State if positive or negative shift. d) 1 month later piece 2 is measured again. = 0.729 a. Calculate the stability shift. b. Calculate the combined accuracy. c. State the 99% range in true readings. d. Calculate the maximum possible deflection. State if positive or negative shift. e) A production batch of camshafts goes thru quality control. The sample size set n = 5 and a. the = 0.0372. b. Determine the total process capability. c. What is the true process capability? (ie remove the effect of gauge capability) d. Comment if the gauge capability influences the total process capability.

GAUGE CAPABILITY WORKSHEET Part 5 0.723 1st Trial 2nd Trial 3rd Trial Range Part 1 0.723 0.723 0.725 Part 2 0.725 0.727 0.724 Part 3 0.728 0.725 0.724 Part 4 0.724 0.728 0.725 Part 6 0.728 0.728 0.728 Part 7 0.723 0.724 0.722 Part 8 0.727 0.729 0.727 Part 9 0.724 0.725 0.725 Part 10 0.728 0.729 0.726 0.725 0.723 sum x-bara= x-bara= R-bara= OPERATOR OPERATOR OPERATOR 1st Trial 2nd Trial 3rd Trial Range 0.721 0.724 0.725 0.726 0.723 0.725 0.727 0.725 0.728 0.726 0.728 0.729 0.724 0.726 0.724 0.726 0.727 0.725 0.723 0.721 0.721 0.725 0.729 0.727 0.726 0.724 0.726 0.727 0.727 0.727 sum x-bars= x-bars= R-barg= 1st Trial 2nd Trial 3rd Trial Range 0.722 0.723 0.723 0.726 0.726 0.723 0.729 0.727 0.726 0.728 0.727 0.729 0.727 0.725 0.724 0.725 0.724 0.728 0.722 0.724 0.725 0.728 0.728 0.728 0.727 0.725 0.726 0.727 0.729 0.729 sum x-barc= x-barc= R-barc= + tolerance Specification Limits USL MSV LSL Part Averages X-bardiff = Max[x-bar] - Min[x-bar] = UCLR = R-bar *D4 = X-db-bar= R-bar- x-bardiff UCLR= Constants Constants Measurement Unit Analysis Repeatability-Equipment Variation (EV): E.V. = # Operators k, # Trails ki D4 2 3 3.65 2.70 2 3 4.56 3.05 3.267 2.575 Reproducibility - Appraiser Variation (AV): A.V. = Repeatability & Reproducibility - (R&R): R&R = R % Tolerance Analysis tol = %EV = %AV = % R+R = Acceptability Criteria = GAUGE CAPABILITY WORKSHEET Part 5 0.723 1st Trial 2nd Trial 3rd Trial Range Part 1 0.723 0.723 0.725 Part 2 0.725 0.727 0.724 Part 3 0.728 0.725 0.724 Part 4 0.724 0.728 0.725 Part 6 0.728 0.728 0.728 Part 7 0.723 0.724 0.722 Part 8 0.727 0.729 0.727 Part 9 0.724 0.725 0.725 Part 10 0.728 0.729 0.726 0.725 0.723 sum x-bara= x-bara= R-bara= OPERATOR OPERATOR OPERATOR 1st Trial 2nd Trial 3rd Trial Range 0.721 0.724 0.725 0.726 0.723 0.725 0.727 0.725 0.728 0.726 0.728 0.729 0.724 0.726 0.724 0.726 0.727 0.725 0.723 0.721 0.721 0.725 0.729 0.727 0.726 0.724 0.726 0.727 0.727 0.727 sum x-bars= x-bars= R-barg= 1st Trial 2nd Trial 3rd Trial Range 0.722 0.723 0.723 0.726 0.726 0.723 0.729 0.727 0.726 0.728 0.727 0.729 0.727 0.725 0.724 0.725 0.724 0.728 0.722 0.724 0.725 0.728 0.728 0.728 0.727 0.725 0.726 0.727 0.729 0.729 sum x-barc= x-barc= R-barc= + tolerance Specification Limits USL MSV LSL Part Averages X-bardiff = Max[x-bar] - Min[x-bar] = UCLR = R-bar *D4 = X-db-bar= R-bar- x-bardiff UCLR= Constants Constants Measurement Unit Analysis Repeatability-Equipment Variation (EV): E.V. = # Operators k, # Trails ki D4 2 3 3.65 2.70 2 3 4.56 3.05 3.267 2.575 Reproducibility - Appraiser Variation (AV): A.V. = Repeatability & Reproducibility - (R&R): R&R = R % Tolerance Analysis tol = %EV = %AV = % R+R = Acceptability Criteria =

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts