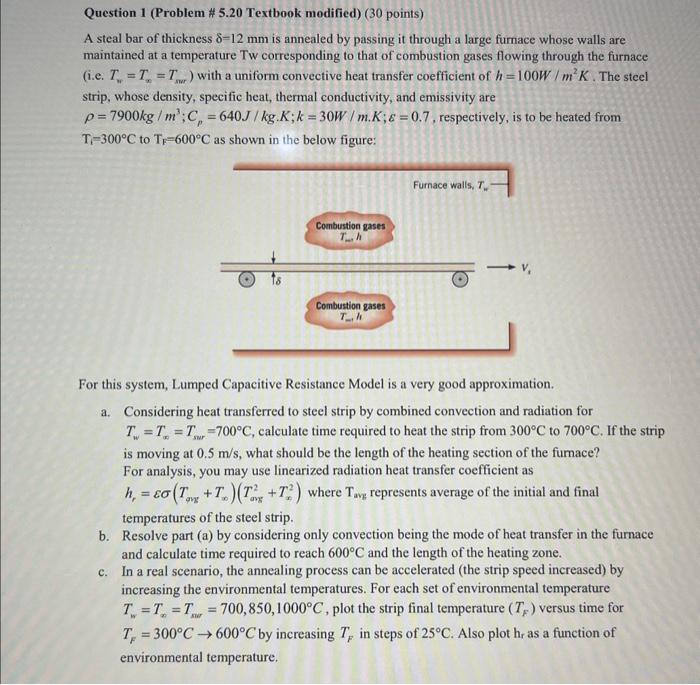

Question: Question 1 (Problem # 5.20 Textbook modified) ( 30 points) A steal bar of thickness =12mm is annealed by passing it through a large furnace

Question 1 (Problem \# 5.20 Textbook modified) ( 30 points) A steal bar of thickness =12mm is annealed by passing it through a large furnace whose walls are maintained at a temperature Tw corresponding to that of combustion gases flowing through the furnace (i.e. Tv=Tn=Tsmr ) with a uniform convective heat transfer coefficient of h=100W/m2K. The steel strip, whose density, specific heat, thermal conductivity, and emissivity are =7900kg/m3;Cp=640J/kg.K;k=30W/m.K;=0.7, respectively, is to be heated from T1=300C to TF=600C as shown in the below figure: For this system, Lumped Capacitive Resistance Model is a very good approximation. a. Considering heat transferred to steel strip by combined convection and radiation for Tw=T=Tswr=700C, calculate time required to heat the strip from 300C to 700C. If the strip is moving at 0.5m/s, what should be the length of the heating section of the furnace? For analysis, you may use linearized radiation heat transfer coefficient as hr=(Tavg+T)(Tar2+Tx2) where Tavg represents average of the initial and final temperatures of the steel strip. b. Resolve part (a) by considering only convection being the mode of heat transfer in the furnace and calculate time required to reach 600C and the length of the heating zone. c. In a real scenario, the annealing process can be accelerated (the strip speed increased) by increasing the environmental temperatures. For each set of environmental temperature Tw=T=Tmir=700,850,1000C, plot the strip final temperature (TF) versus time for TF=300C600C by increasing TF in steps of 25C. Also plot hr as a function of environmental temperature

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts