Question: Question 1 : Process Capacity Analysis A manufacturing plant produces widgets using three machines operating in parallel. Machine A produces 1 2 0 widgets per

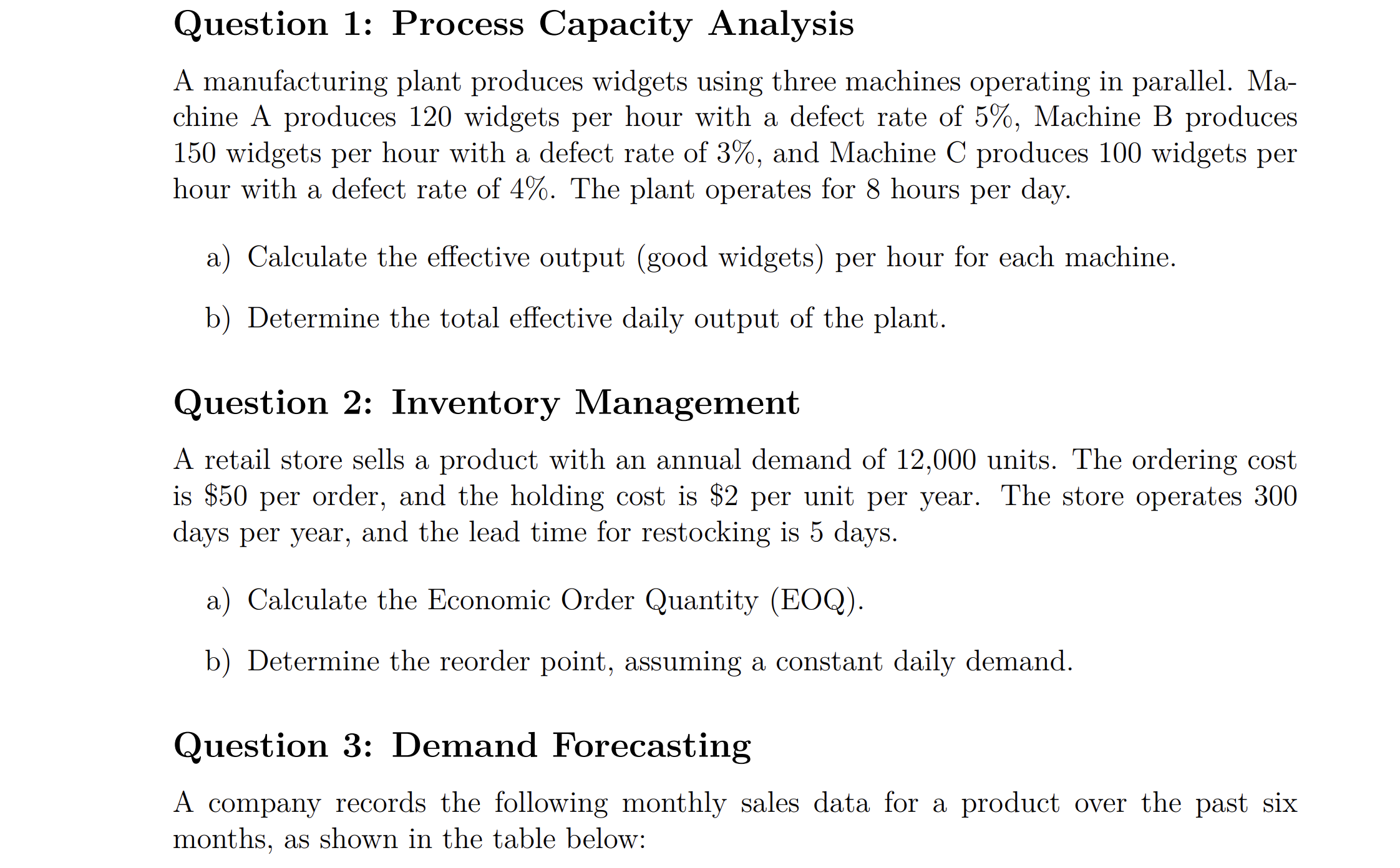

Question : Process Capacity Analysis

A manufacturing plant produces widgets using three machines operating in parallel. Machine A produces widgets per hour with a defect rate of Machine B produces widgets per hour with a defect rate of and Machine C produces widgets per hour with a defect rate of The plant operates for hours per day.

aCalculate the effective output good widgetsper hour for each machine.

bDetermine the total effective daily output of the plant.

Question : Inventory Management

A retail store sells a product with an annual demand of units The ordering cost is $ per order, and the holding cost is $ per unit per year. The store operates days per year, and the lead time for restocking is days

aCalculate the Economic Order Quantity EOQ

bDetermine the reorder point, assuming a constant daily demand.

Question : Demand Forecasting

A company records the following monthly sales data for a product over the past six months, as shown in the table below:

Question : Demand Forecasting

A company records the following monthly sales data for a product over the past six

months, as shown in the table below:

Table : Monthly Sales Data

a Using a month moving average, forecast the demand for the next month month

b Using exponential smoothing with a smoothing constant of and assuming the

forecast for month was units, calculate the forecast for month

Question : Production Scheduling

A factory produces two products, X and Y on a single machine. The machine requires a

setup time of hours when switching from X to Y and hours when switching from Y

to X Product X takes hours per unit to produce, and Product Y takes hours per

unit. The factory needs to produce units of X and units of Y in a week, and the

machine is available for hours.

a Calculate the total production time required for both products excluding setup

times

b Determine the minimum number of setups required and the total time production

setup to meet the demand. Assume the factory can choose the production

sequence.

Question : Process Flowchart

Based on the production process described in Question draw a flowchart to illustrate the

sequence of steps for producing Products X and Y Include the following steps: receiving

raw materials, setting up the machine, producing Product X producing Product Y

inspecting finished products, and packaging. Clearly indicate decision points for switching

between products and any looping structures for repeated production.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock