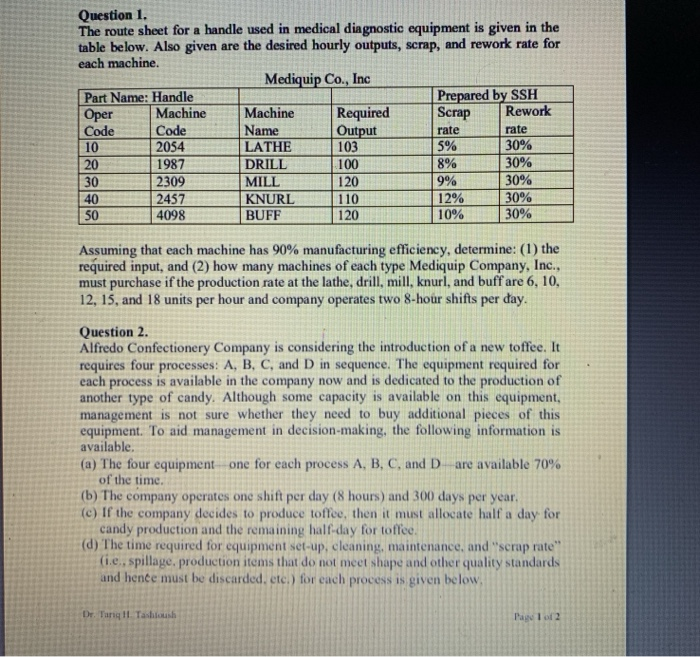

Question: Question 1. The route sheet for a handle used in medical diagnostic equipment is given in the table below. Also given are the desired hourly

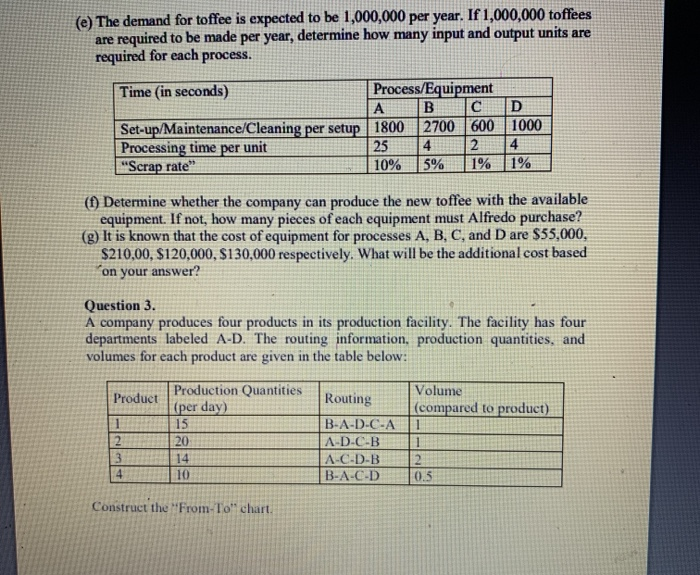

Question 1. The route sheet for a handle used in medical diagnostic equipment is given in the table below. Also given are the desired hourly outputs, scrap, and rework rate for each machine. Mediquip Co., Inc Part Name: Handle Prepared by SSH Oper Machine Machine Required Scrap Rework Code Code Name Output rate rate 10 2054 LATHE 103 5% 30% 20 1987 DRILL 100 8% 30% 30 2309 MILL 120 9% 30% 40 2457 KNURL 110 12% 30% 50 4098 BUFF 120 10% 30% Assuming that each machine has 90% manufacturing efficiency, determine: (1) the required input, and (2) how many machines of each type Mediquip Company, Inc., must purchase if the production rate at the lathe, drill, mill, knurl, and buffare 6, 10, 12, 15, and 18 units per hour and company operates two 8-hour shifts per day. Question 2. Alfredo Confectionery Company is considering the introduction of a new toffee. It requires four processes: A, B, C, and D in sequence. The equipment required for each process is available in the company now and is dedicated to the production of another type of candy. Although some capacity is available on this equipment, management is not sure whether they need to buy additional pieces of this equipment. To aid management in decision-making, the following information is available (a) The four equipment one for each process A, B, C, and D are available 70% of the time. (b) The company operates one shift per day (8 hours) and 300 days per year. (c) If the company decides to produce toffee, then it must allocate half a day for candy production and the remaining half-day for toffee. (d) The time required for equipment set-up, cleaning, maintenance, and "scrap rate" (ie, spillage, production items that do not meet shape and other quality standards and hence must be discarded, etc.) for each process is given below. Dr. Tangil Tashoush Page 1 of 2 () The demand for toffee is expected to be 1,000,000 per year. If 1,000,000 toffees are required to be made per year, determine how many input and output units are required for each process. Time (in seconds) Process/Equipment B D Set-up/Maintenance/Cleaning per setup 1800 2700 600 1000 Processing time per unit 25 4 2 4 "Scrap rate" 10% 5% 1% 1% (1) Determine whether the company can produce the new toffee with the available equipment. If not, how many pieces of each equipment must Alfredo purchase? (g) It is known that the cost of equipment for processes A, B, C, and D are $55,000, $210,00, $120,000, $130,000 respectively. What will be the additional cost based on your answer? Question 3. A company produces four products in its production facility. The facility has four departments labeled A-D. The routing information, production quantities, and volumes for each product are given in the table below: Routing Volume (compared to product) Product 1 2 Production Quantities (per day) 15 20 14 10 1 B-A-D-C-A A-D-C-B A-C-D-B B-A-C-D 4 2 0.5 Construct the "From-To" chart