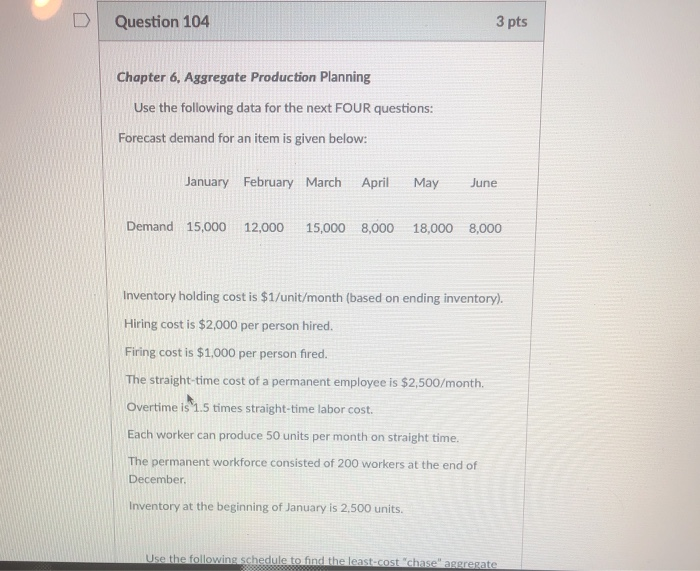

Question: Question 104 3 pts Chapter 6, Aggregate Production Planning Use the following data for the next FOUR questions: Forecast demand for an item is given

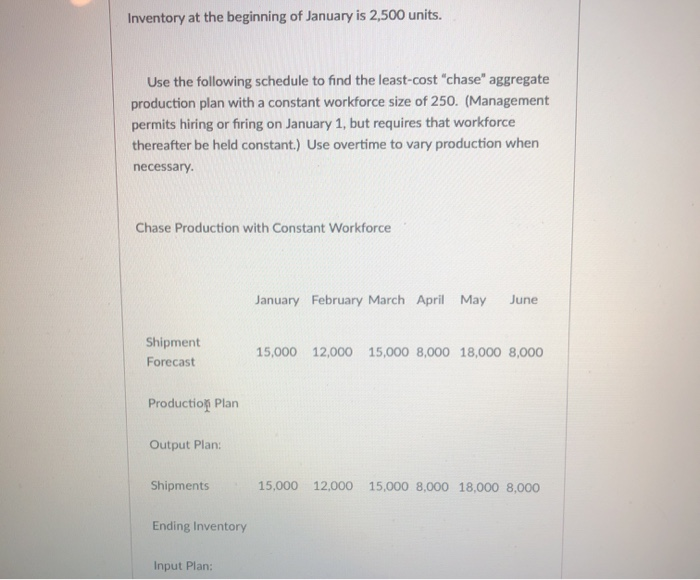

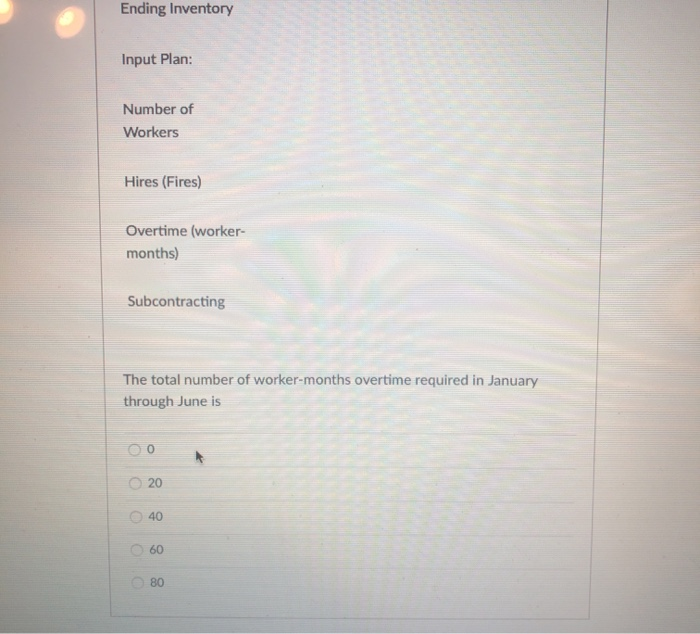

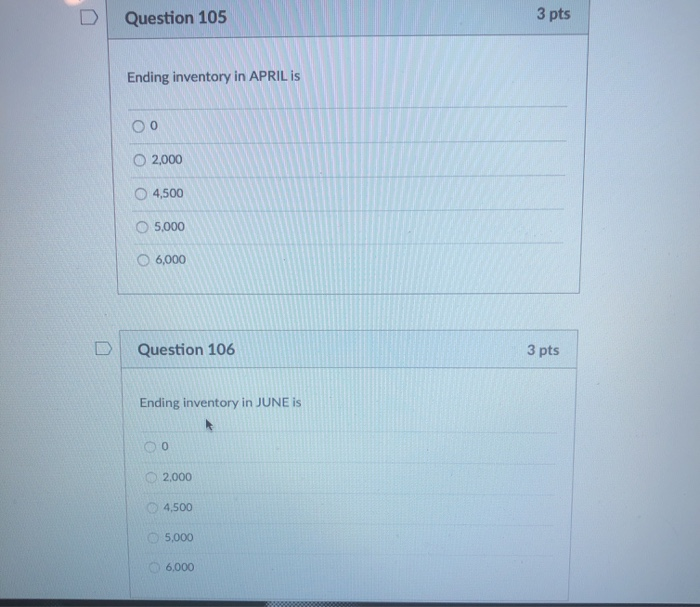

Question 104 3 pts Chapter 6, Aggregate Production Planning Use the following data for the next FOUR questions: Forecast demand for an item is given below: January February March April May June Demand 15,000 12,000 15,000 8,000 18,000 8,000 Inventory holding cost is $1/unit/month (based on ending inventory). Hiring cost is $2,000 per person hired. Firing cost is $1,000 per person fired. The straight-time cost of a permanent employee is $2,500/month Overtime is 1.5 times straight-time labor cost. Each worker can produce 50 units per month on straight time. The permanent workforce consisted of 200 workers at the end of December Inventory at the beginning of January is 2.500 units. Use the following schedule to find the least-cost "chase aggregate Inventory at the beginning of January is 2,500 units. Use the following schedule to find the least-cost "chase" aggregate production plan with a constant workforce size of 250. (Management permits hiring or firing on January 1, but requires that workforce thereafter be held constant.) Use overtime to vary production when necessary. Chase Production with Constant Workforce January February March April May June Shipment Forecast 15,000 12,000 15,000 8,000 18,000 8,000 Production Plan Output Plan: Shipments 15.000 12.000 15,000 8,000 18,000 8,000 Ending Inventory Input Plan: Ending Inventory Input Plan: Number of Workers Hires (Fires) Overtime (worker- months) Subcontracting The total number of worker-months overtime required in January through June is 0 20 40 0 0 C 60 80 Question 105 3 pts Ending inventory in APRIL is O 2,000 4,500 5,000 6,000 Question 106 3 pts Ending inventory in JUNE is OO 2,000 4,500 5,000 6,000 Question 107 3 pts The total cost of this aggregate production plan is $3,975,000 O $3,984,500 $4,075,000 $4,084,500 $4,125,000 Question 108 3 pts Chapter 7, Capacity Planning with Queuing and Simulation Models