Question: Question 11 question 2 For the plan presented in the table below, it has been shown that 76 workers in 22 days have produced 245

Question 11

question 2

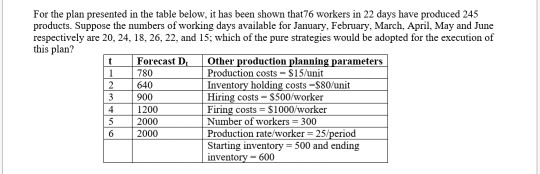

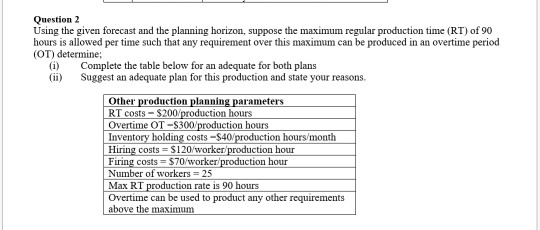

For the plan presented in the table below, it has been shown that 76 workers in 22 days have produced 245 products. Suppose the numbers of working days available for January, February March April, May and June respectively are 20, 24, 18, 26, 22, and 15, which of the pure strategies would be adopted for the execution of this plan? Forecast D. Other production planning parameters 780 Production costs - S15/unit 2 640 Inventory holding costs -$80/unit 3 900 Hiring costs - $500/worker 1200 Firing costs = $1000/worker 2000 Number of workers = 300 2000 Production rate/worker = 25/period Starting inventory = 500 and ending inventory - 600 4 5 6 Question 2 Using the given forecast and the planning horizon, suppose the maximum regular production time (RT) of 90 hours is allowed per time such that any requirement over this maximum can be produced in an overtime period (OT) determine: (i) Complete the table below for an adequate for both plans Suggest an adequate plan for this production and state your reasons. Other production planning parameters RT costs - $200/production hours Overtime OT -S300/production hours Inventory holding costs -$40/production hours/month Hiring costs = $120/worker' production hour Firing costs = $70/worker production hour Number of workers = 25 Max RT production rate is 90 hours Overtime can be used to product any other requirements above the maximum For the plan presented in the table below, it has been shown that 76 workers in 22 days have produced 245 products. Suppose the numbers of working days available for January, February March April, May and June respectively are 20, 24, 18, 26, 22, and 15, which of the pure strategies would be adopted for the execution of this plan? Forecast D. Other production planning parameters 780 Production costs - S15/unit 2 640 Inventory holding costs -$80/unit 3 900 Hiring costs - $500/worker 1200 Firing costs = $1000/worker 2000 Number of workers = 300 2000 Production rate/worker = 25/period Starting inventory = 500 and ending inventory - 600 4 5 6 Question 2 Using the given forecast and the planning horizon, suppose the maximum regular production time (RT) of 90 hours is allowed per time such that any requirement over this maximum can be produced in an overtime period (OT) determine: (i) Complete the table below for an adequate for both plans Suggest an adequate plan for this production and state your reasons. Other production planning parameters RT costs - $200/production hours Overtime OT -S300/production hours Inventory holding costs -$40/production hours/month Hiring costs = $120/worker' production hour Firing costs = $70/worker production hour Number of workers = 25 Max RT production rate is 90 hours Overtime can be used to product any other requirements above the maximum

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock