Question: Question 16.3, please a) What is the setup cost, based on the desired lot siz! b) What is the setup time, based on S40 per

Question 16.3, please

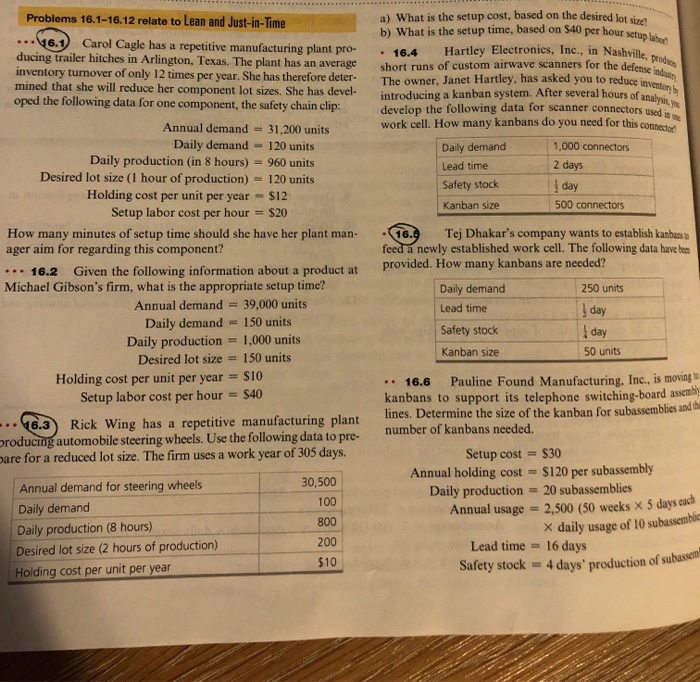

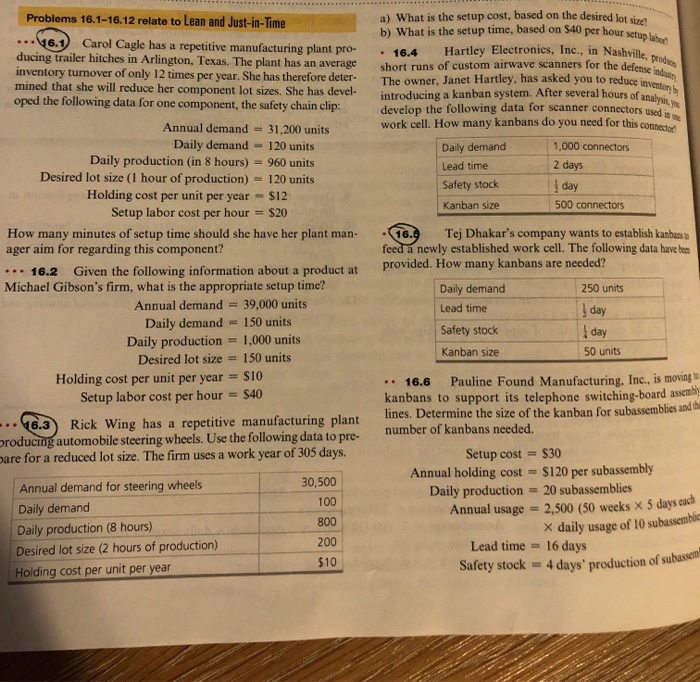

a) What is the setup cost, based on the desired lot siz! b) What is the setup time, based on S40 per hour setup lato Hartley Electronics, Inc., in Nashville, peolen short runs of custom airwave scanners for the defense introducing a kanban system. After several hours of analysis, you The owner, Janet Hartley, has asked you to reduce invention work cell. How many kanbans do you need for this connector Safety stock = 4 days' production of subassem Problems 16.1-16.12 relate to Lean and Just-in-Time ...16.1 Carol Cagle has a repetitive manufacturing plant pro- ducing trailer hitches in Arlington, Texas. The plant has an average 16.4 inventory turnover of only 12 times per year. She has therefore deter- mined that she will reduce her component lot sizes. She has devel- oped the following data for one component, the safety chain clip: Annual demand = 31,200 units Daily demand = 120 units Daily demand 1,000 connectors Daily production (in 8 hours) = 960 units Lead time 2 days Desired lot size (1 hour of production) = 120 units Holding cost per unit per year - $12 Safety stock day Setup labor cost per hour = $20 Kanban size 500 connectors How many minutes of setup time should she have her plant man. 16.9 Tej Dhakar's company wants to establish kanbans to ager aim for regarding this component? feed a newly established work cell. The following data have been ... 16.2 Given the following information about a product at provided. How many kanbans are needed? Michael Gibson's firm, what is the appropriate setup time? Daily demand 250 units Annual demand = 39.000 units Lead time \ day Daily demand = 150 units Safety stock Daily production 1,000 units Kanban size Desired lot size 150 units 50 units Holding cost per unit per year = $10 .. 16.6 Pauline Found Manufacturing, Inc., is moving 1 Setup labor cost per hour S40 kanbans to support its telephone switching-board assembly lines. Determine the size of the kanban for subassemblies and the Rick Wing has a repetitive manufacturing plant number of kanbans needed. producing automobile steering wheels. Use the following data to pre- bare for a reduced lot size. The firm uses a work year of 30 days. Setup cost = $30 Annual holding cost = $120 per subassembly Annual demand for steering wheels 30,500 Daily production 20 subassemblies 100 Daily demand Annual usage 2,500 (50 weeks 5 days cach 800 Daily production (8 hours) 200 Desired lot size (2 hours of production) Lead time = $10 Holding cost per unit per year day .. 6.3 * daily usage of 10 subassemble 16 days