Question: Question 2 (10 Marks) The MPC system at 123 Ltd is run weekly to update the master production schedule (MPS) and MRP records. At the

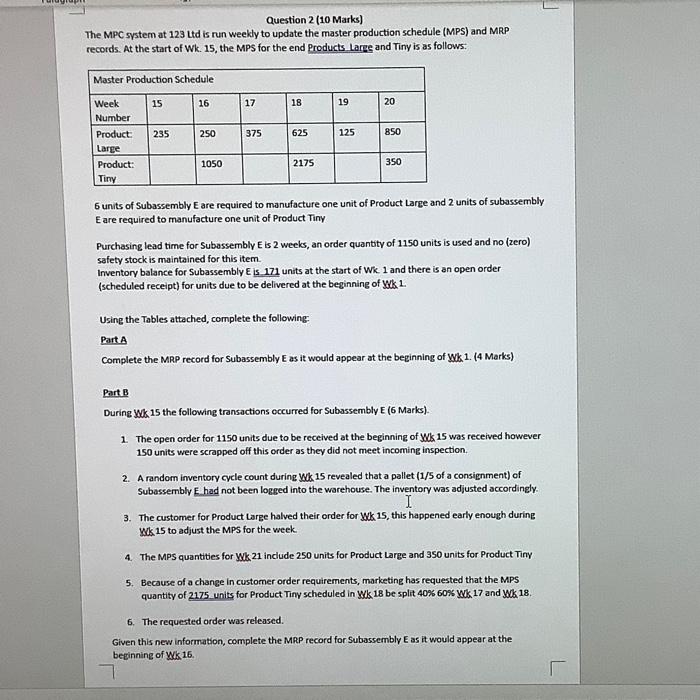

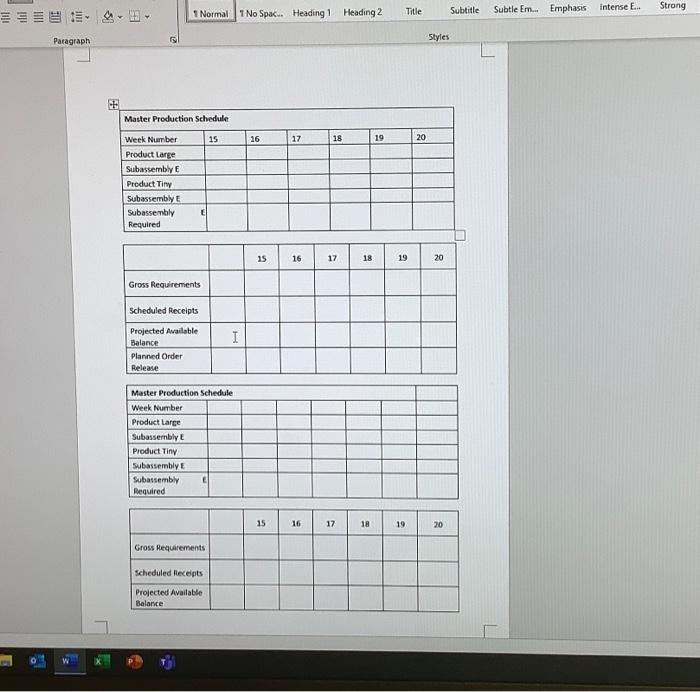

Question 2 (10 Marks) The MPC system at 123 Ltd is run weekly to update the master production schedule (MPS) and MRP records. At the start of Wk. 15, the MPS for the end Products Large and Tiny is as follows: 6 units of Subassembly E are required to manufacture one unit of Product Large and 2 units of subassembly E are required to manufacture one unit of Product Tiny Purchasing lead time for Subassembly E is 2 weeks, an order quantity of 1150 units is used and no (zero) safety stock is maintained for this item. Inventory balance for Subassembly is.171 units at the start of WK. 1 and there is an open order (scheduled receipt) for units due to be delivered at the beginning of W/K 1. Using the Tables attached, complete the following: Part A Complete the MRP record for Subassembly E as it would appear at the beginning of Wk. 1. ( 4 Marks) Part B During Wak, 15 the following transactions occurred for Subassembly E ( 6 Marks). 1. The open order for 1150 units due to be received at the beginning of Wk. 15 was received however 150 units were scrapped off this order as they did not meet incoming inspection. 2. A random inventory cycle count during WK. 15 revealed that a pallet ( 1/5 of a consignment) of Subassembly E had not been logged into the warehouse. The inventory was adjusted accordingly. I 3. The customer for Product Large halved their order for Wk 15, this happened early enough during Wh. 15 to adjust the MPS for the week. 4. The MPS quantities for Wk, 21 include 250 units for Product Large and 350 units for Product Tiny 5. Because of a change in customer order requirements, marketing has requested that the MPS quantity of 2175 units for Product Tiny scheduled in WKk, 18 be split 40\% 60\% WKk. 17 and WKk 18. 6. The requested order was released. Given this new information, complete the MRP record for Subassembly E as it would appear at the beginning of Wk. 16. I Normal TNo Spac.. Heading 1 Heading 2 Title Subtitle Subtle Em... Emphasis intense E.. Strong Pacagraph 5. Styles Master Production Schedule \begin{tabular}{|l|l|l|l|l|l|l|} \hline Week Number & 15 & 16 & 17 & 18 & 19 & 20 \\ \hline Product Large & & & & & & \\ \hline Subassembly E & & & & & & \\ \hline Product Tiny & & & & & & \\ \hline \begin{tabular}{l} Subassembly E \\ Rubassembly \\ Required \end{tabular} & & & & & & \\ \hline \end{tabular} \begin{tabular}{|l|l|l|l|l|l|l|l|} \hline & & 15 & 16 & 17 & 18 & 19 & 20 \\ \hline Gross Requirements & & & & & & & \\ \hline Scheduled Receipts & & & & & & & \\ \hline \begin{tabular}{l} Projected Available \\ Balance \end{tabular} & I & & & & & & \\ \hline \begin{tabular}{l} Planned Order \\ Release \end{tabular} & & & & & & & \\ \hline \end{tabular} \begin{tabular}{|l|l|l|l|l|l|l|l|} \hline & & 15 & 16 & 17 & 18 & 19 & 20 \\ \hline Gross Requicments & & & & & & & \\ \hline Scheduled fleceipts & & & & & & & \\ \hline \begin{tabular}{l} Projected Available \\ Balarce \end{tabular} & & & & & & & \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts