Question: QUESTION 2 a) Consider a product with a daily demand of 400 units, a setup cost per production run of K100, a monthly holding cost

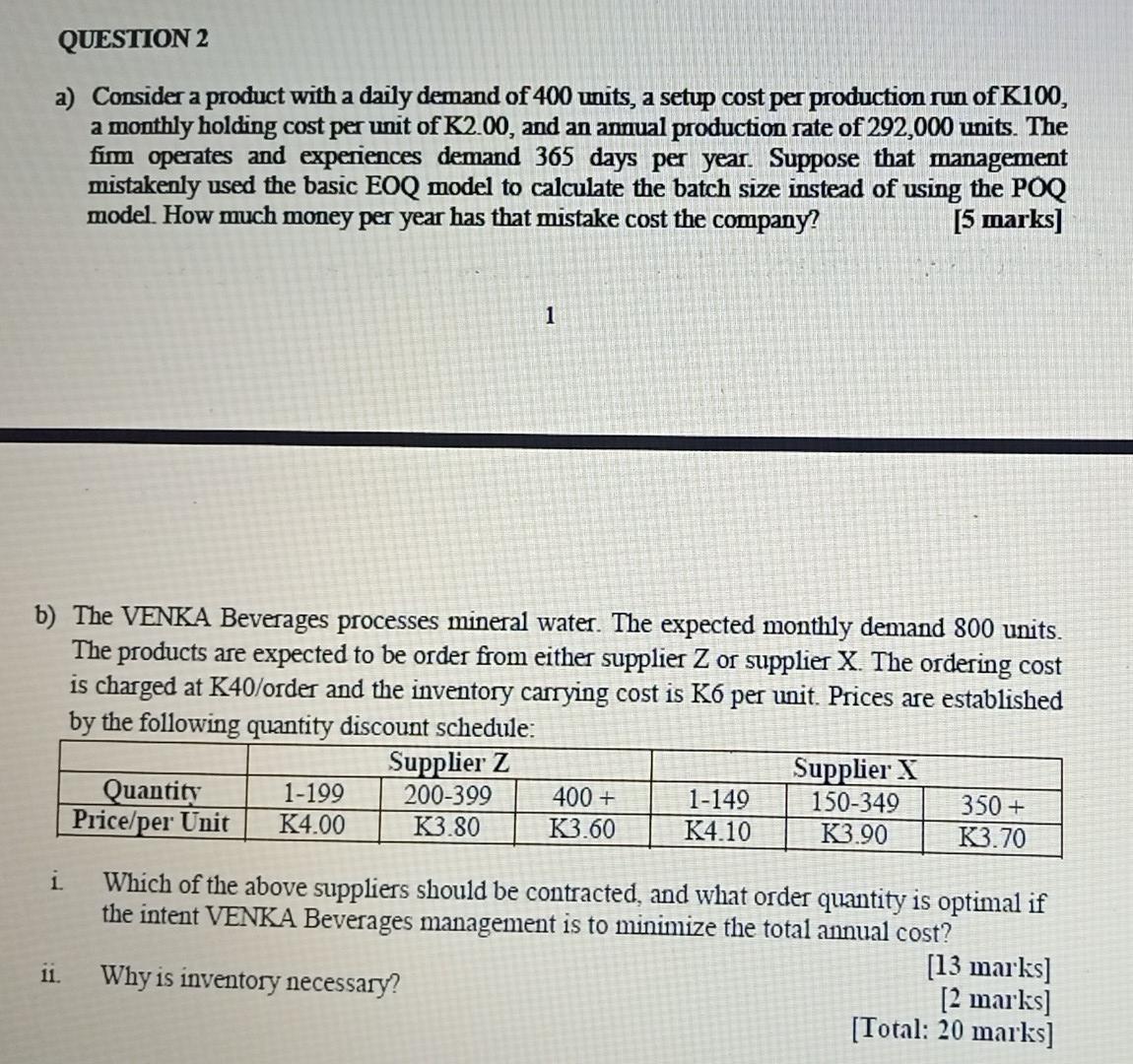

QUESTION 2 a) Consider a product with a daily demand of 400 units, a setup cost per production run of K100, a monthly holding cost per unit of K2.00, and an annual production rate of 292,000 units. The firm operates and experiences demand 365 days per year. Suppose that management mistakenly used the basic EOQ model to calculate the batch size instead of using the POQ model. How much money per year has that mistake cost the company? [5 marks) 1 b) The VENKA Beverages processes mineral water. The expected monthly demand 800 units. The products are expected to be order from either supplier Z or supplier X. The ordering cost is charged at K40/order and the inventory carrying cost is K6 per unit. Prices are established by the following quantity discount schedule: Supplier Z Supplier X Quantity 1-199 200-399 400 + 1-149 150-349 350+ Price/per Unit K4.00 K3.80 K3.60 K4.10 K3.90 K3.70 Which of the above suppliers should be contracted, and what order quantity is optimal if the intent VENKA Beverages management is to minimize the total annual cost? [13 marks] Why is inventory necessary? [2 marks] [Total: 20 marks) 11

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock