Question: Question 2 Chapter 10: Consider Managerial Practice 10.1 on page 410 of the textbook and the scheduling of Major League Baseball umpires. Relate the three

Question 2

Chapter 10: Consider Managerial Practice 10.1 on page 410 of the textbook and the scheduling of Major League Baseball umpires. Relate the three levels in Figure 10.2 on page 400 to the seasonal production of baseball games (about 300-400 words).

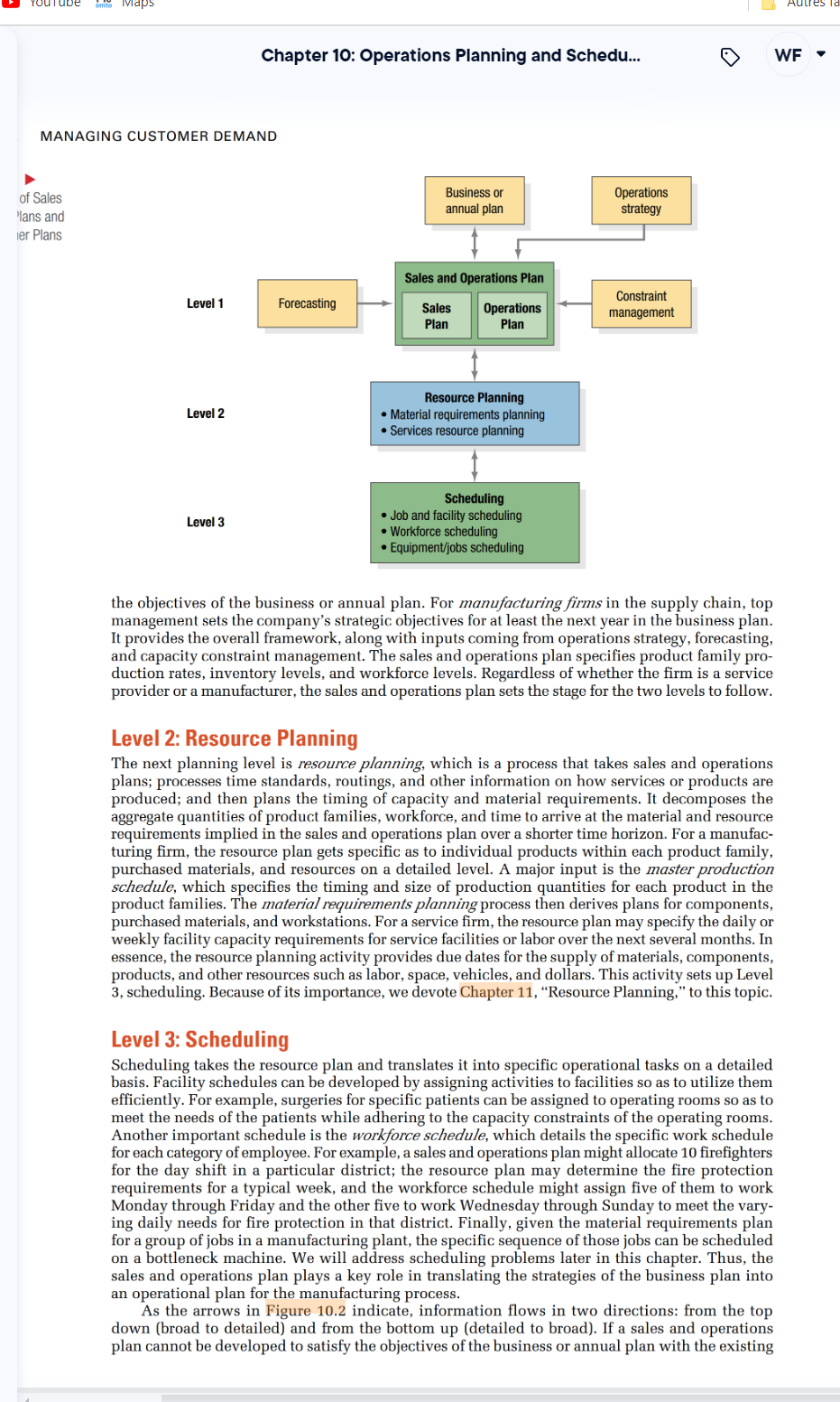

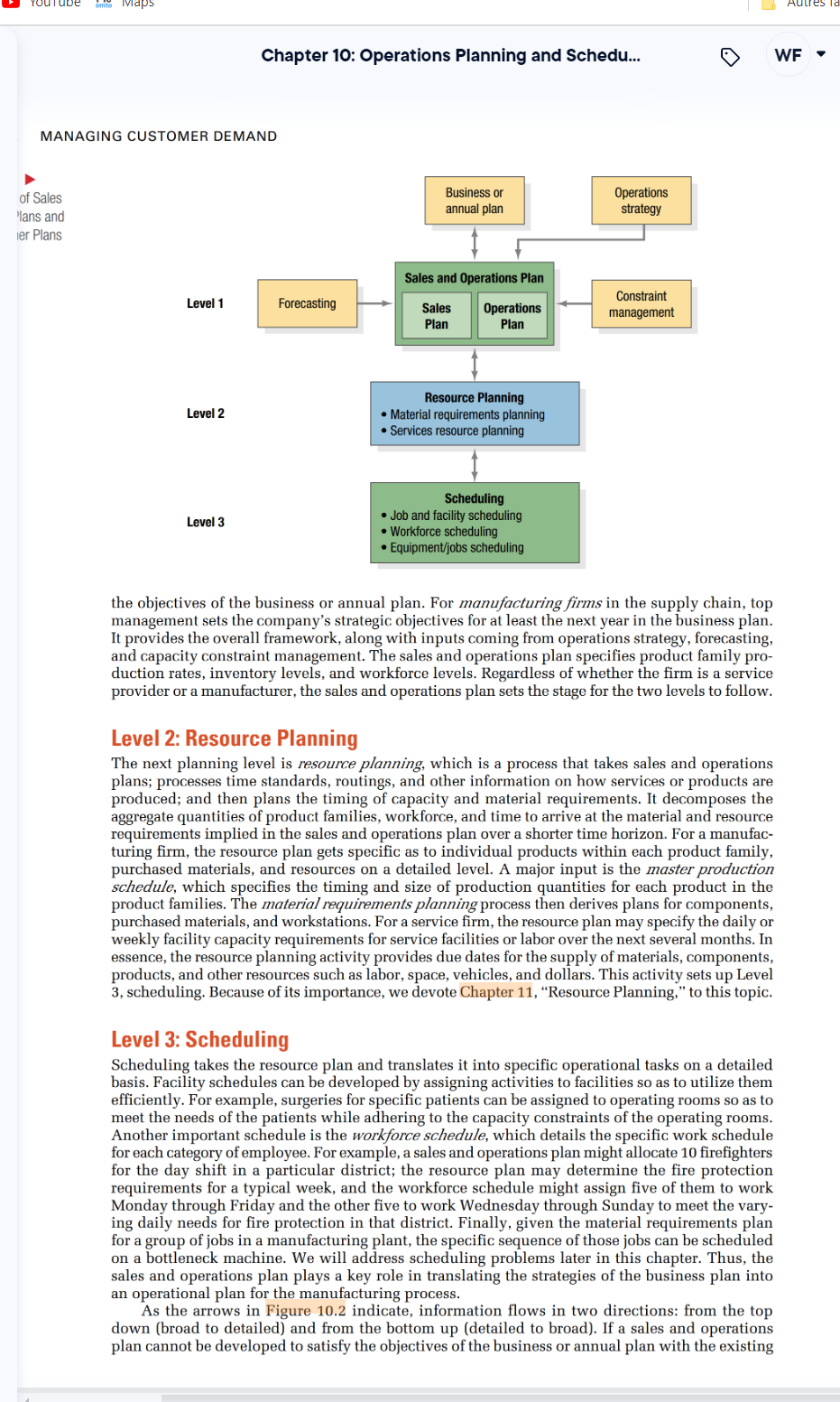

410 PART 2 MANAGING CUSTOMER DEMAND MANAGERIAL PRACTICE It's 7:07 p.m. on October 30, 2019, at Minute Maid Park in Houston, Texas. The Houston Astros and the Washington Nationals are playing game 7 of the World Series, the deciding game. The stadium is rocking with 43,326 fans, and 40 million more are watching the event on television in the United States alone. Astros pitcher, Zack Greinke, prepares to fire the first pitch to Nationals shortstop Trea Turner, and home-plate umpire Sam Holbrook leans down to call the balls and strikes. The Nationals won 62 and won the World Series 4 games to 3 . There was a lot of press about the performances of the players; however, the umpires largely went unnoticed. Yet, the game could not have been played without them. Each year, 30 teams in Major League Baseball (MLB) play 2,430 games in 780 series during a 6-month season. Each series, defined as a sequence of two to four games played consecutively between two opponents, requires a crew of four umpires. Each crew stays together for the entire season and gets scheduled as a unit. An umpire's job is full time, working about 142 games a year and spending most of his time traveling. Unlike a baseball player, whose team has a home city and plays half of its games there, an umpire who lives near a team's home city will not be able to work half of his games there. The reason is that MLB does not want an umpire working the games of any one team too frequently in one season. Consequently, umpires must travel after the completion of a series. A typical umpire crew may travel up to 35,000 miles during the season. Before you submit your resume for the position of umpire scheduler, let's take a look at the complexity of the problem. There are 17 umpire crews - Crews should not work more than 21 days without a day off in the staffing plan. Because of union vacation requirements, each week (21-day rule). 15 crews are available to schedule a series. The schedule of games has - Umpiring more than one series played by any team within an 18-day already been developed, so the problem is to assign crews to series so as to period should be avoided (18-day rule). minimize the number of miles traveled by each crew. Now comes the hard - Working more than four series played by any one team during the entire part. There are many constraints that any solution must recognize. Here are season should be avoided (four-series rule). several examples: Beyond these constraints, the crews should travel to every MLB city, work - Crews traveling from the West Coast to the East Coast must have an each team at home and on the road, and have roughly equivalent schedules intermediate day off. regarding travel and vacations. Creating these schedules manually would be - Working consecutive series more than 1,700 miles apart must have an mindboggling. Fortunately, Raquel Wagner, MLB Manager of Umpire Operations, intermediate day off. has access to powerful mathematical models to help. Resumes, anyone?2 a period of time, each person has the same opportunity to have weekends and holidays off and to work days, as well as evenings and nights. A rotating schedule gives each employee the next fixed schedule employee's schedule the following week. In contrast, a fixed schedule calls for each employee to A schedule that calls for each work the same days and hours each week. employee to work the same days Developing a Workforce Schedule Suppose that we are interested in developing a workforce and hours each week. schedule for a company that operates 7 days a week and provides each employee with 2 consecutive days off. In this section, we demonstrate a method that recognizes this constraint. The objective is to identify the 2 consecutive days off for each employee that will minimize the amount of total slack capacity, thereby maximizing the utilization of the workforce. The work schedule for each employee, then, is the 5 days that remain after the 2 days off have been determined. The procedure involves the following steps. Step 1. From the schedule of net requirements for the week, derived from the resource plan in Level 2, find all the pairs of consecutive days, excluding the day (or days) with the maximum daily requirement. Select the unique pair that has the lowest total requirements for the 2 days. In some unusual situations, all pairs may contain a day with the maximum requirements. the Travelling Umpire Problem," Interfaces vol. 42, no. 3 (May-June 2012), pp. 232-244; Ted Berg, "Umpiring a World Series Game is Extremely Hard and MLB Umps Are Great at It," http://ftw.usatoday.com (November 1, 2016); https:/en.wikipedia.org/wiki/2019_World_Series. the objectives of the business or annual plan. For manufacturing firms in the supply chain, top management sets the company's strategic objectives for at least the next year in the business plan. It provides the overall framework, along with inputs coming from operations strategy, forecasting, and capacity constraint management. The sales and operations plan specifies product family production rates, inventory levels, and workforce levels. Regardless of whether the firm is a service provider or a manufacturer, the sales and operations plan sets the stage for the two levels to follow. Level 2: Resource Planning The next planning level is resource planning, which is a process that takes sales and operations plans; processes time standards, routings, and other information on how services or products are produced; and then plans the timing of capacity and material requirements. It decomposes the aggregate quantities of product families, workforce, and time to arrive at the material and resource requirements implied in the sales and operations plan over a shorter time horizon. For a manufacturing firm, the resource plan gets specific as to individual products within each product family, purchased materials, and resources on a detailed level. A major input is the master production schedule, which specifies the timing and size of production quantities for each product in the product families. The material requirements planning process then derives plans for components, purchased materials, and workstations. For a service firm, the resource plan may specify the daily or weekly facility capacity requirements for service facilities or labor over the next several months. In essence, the resource planning activity provides due dates for the supply of materials, components, products, and other resources such as labor, space, vehicles, and dollars. This activity sets up Level 3, scheduling. Because of its importance, we devote Chapter 11, "Resource Planning," to this topic. Level 3: Scheduling Scheduling takes the resource plan and translates it into specific operational tasks on a detailed basis. Facility schedules can be developed by assigning activities to facilities so as to utilize them efficiently. For example, surgeries for specific patients can be assigned to operating rooms so as to meet the needs of the patients while adhering to the capacity constraints of the operating rooms. Another important schedule is the workforce schedule, which details the specific work schedule for each category of employee. For example, a sales and operations plan might allocate 10 firefighters for the day shift in a particular district; the resource plan may determine the fire protection requirements for a typical week, and the workforce schedule might assign five of them to work Monday through Friday and the other five to work Wednesday through Sunday to meet the varying daily needs for fire protection in that district. Finally, given the material requirements plan for a group of jobs in a manufacturing plant, the specific sequence of those jobs can be scheduled on a bottleneck machine. We will address scheduling problems later in this chapter. Thus, the sales and operations plan plays a key role in translating the strategies of the business plan into an operational plan for the manufacturing process. As the arrows in Figure 10.2 indicate, information flows in two directions: from the top down (broad to detailed) and from the bottom up (detailed to broad). If a sales and operations plan cannot be developed to satisfy the objectives of the business or annual plan with the existing