Question: Question 2 ( Core Operations Management ) : A photovoltaic panel producer wants to determine the number of panels that it should produce for the

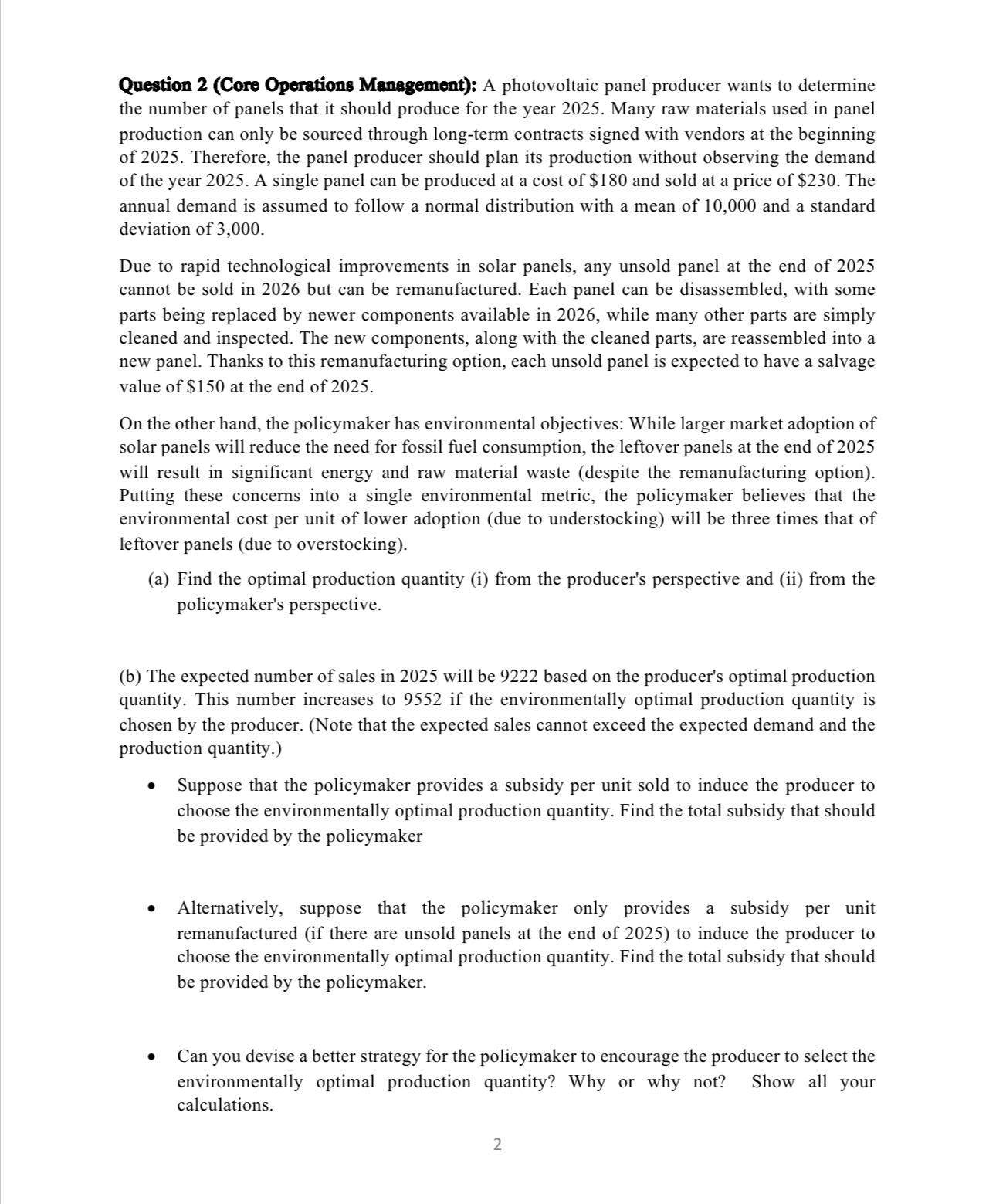

Question Core Operations Management: A photovoltaic panel producer wants to determine the number of panels that it should produce for the year Many raw materials used in panel production can only be sourced through longterm contracts signed with vendors at the beginning of Therefore, the panel producer should plan its production without observing the demand of the year A single panel can be produced at a cost of $ and sold at a price of $ The annual demand is assumed to follow a normal distribution with a mean of and a standard deviation of

Due to rapid technological improvements in solar panels, any unsold panel at the end of cannot be sold in but can be remanufactured. Each panel can be disassembled, with some parts being replaced by newer components available in while many other parts are simply cleaned and inspected. The new components, along with the cleaned parts, are reassembled into a new panel. Thanks to this remanufacturing option, each unsold panel is expected to have a salvage value of $ at the end of

On the other hand, the policymaker has environmental objectives: While larger market adoption of solar panels will reduce the need for fossil fuel consumption, the leftover panels at the end of will result in significant energy and raw material waste despite the remanufacturing option Putting these concerns into a single environmental metric, the policymaker believes that the environmental cost per unit of lower adoption due to understocking will be three times that of leftover panels due to overstocking

a Find the optimal production quantity i from the producer's perspective and ii from the policymaker's perspective.

b The expected number of sales in will be based on the producer's optimal production quantity. This number increases to if the environmentally optimal production quantity is chosen by the producer. Note that the expected sales cannot exceed the expected demand and the production quantity.

Suppose that the policymaker provides a subsidy per unit sold to induce the producer to choose the environmentally optimal production quantity. Find the total subsidy that should be provided by the policymaker

Alternatively, suppose that the policymaker only provides a subsidy per unit remanufactured if there are unsold panels at the end of to induce the producer to choose the environmentally optimal production quantity. Find the total subsidy that should be provided by the policymaker.

Can you devise a better strategy for the policymaker to encourage the producer to select the environmentally optimal production quantity? Why or why not? Show all your calculations.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock